Electromagnetic suspension water-cooling copper crucible

A water-cooled copper crucible and electromagnetic levitation technology, applied in crucible furnaces, furnaces, lighting and heating equipment, etc., can solve the problems of liquid alloy contamination of samples, large temperature gradients, and easy extinguishment of melts, etc., and achieve small solidification structures and high Cleanliness, the effect of avoiding melt contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

[0042] like figure 1 As shown, an electromagnetic levitation water-cooled copper crucible includes a crucible body 1, an induction coil 2, a copper mold 3, a compression plug 4, a rubber pad 5 and an insulating tape 6, the induction coil 2 surrounds the upper part of the crucible body 1, and the copper mold 3 is set In the copper mold cavity 13 of the crucible body 1 and fixed and leak-proof by the compression plug 4 and the rubber pad 5, the upper part of the crucible split 11 on the crucible body 1 is wound with an insulating tape 6.

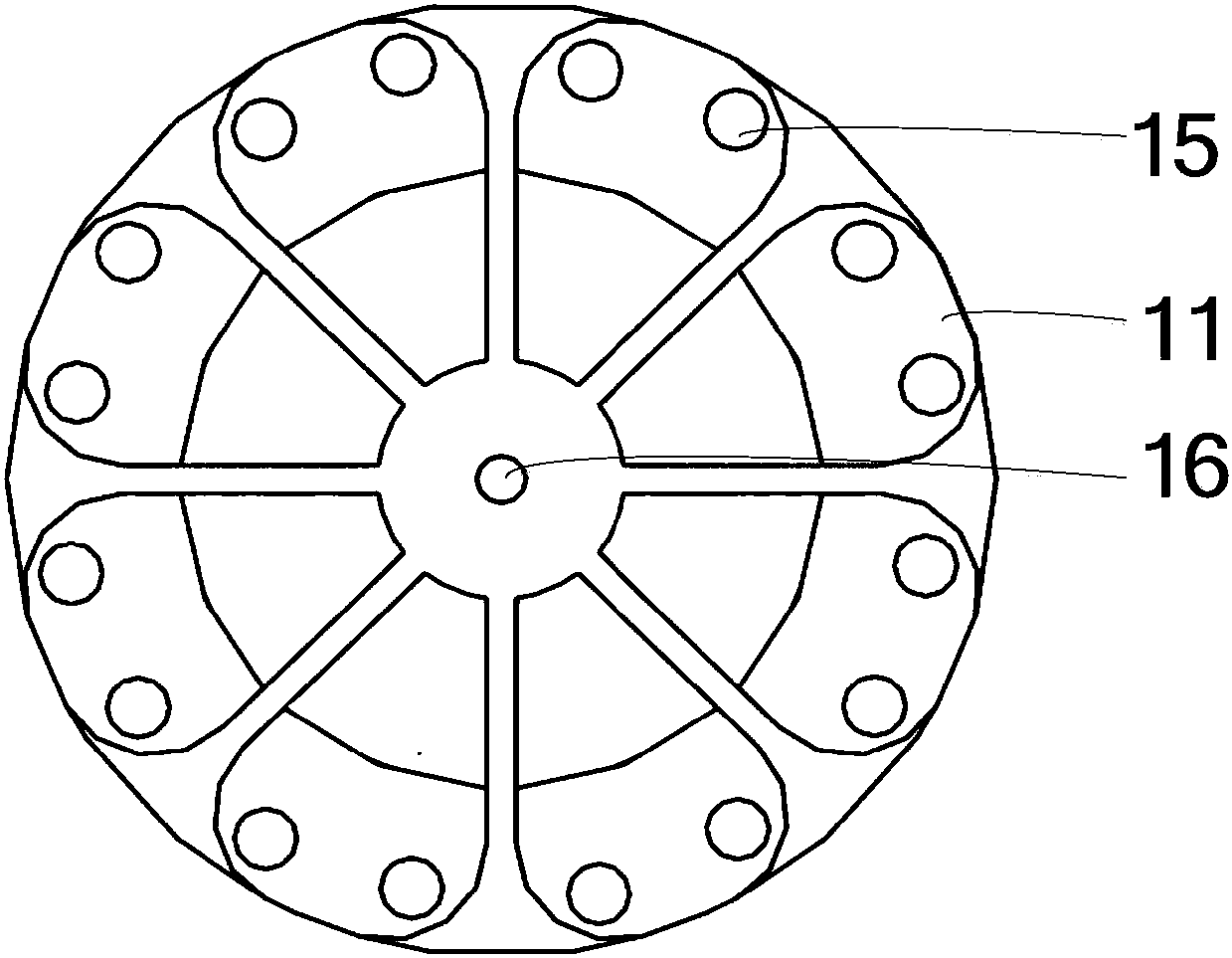

[0043] like figure 2 As shown, the shape of the crucible body 1 is cylindrical, and its upper part includes eight crucible segments 11 distributed in a circle. The crucible segments 11 form an upwardly open melt cavity 12; there are gaps between the crucible segments 11. The valve gap is filled with high tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com