Quick-heat-dissipation anti-disengagement rubber roller

An anti-shedding and rubber roller technology, applied in the field of rubber rollers, can solve the problems of poor heat dissipation effect of solid rubber rollers, shorten the service life of the rubber rollers, increase the production cost of manufacturers, etc., achieve good resistance, increase air intake, and reduce maintenance. The effect of replacement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

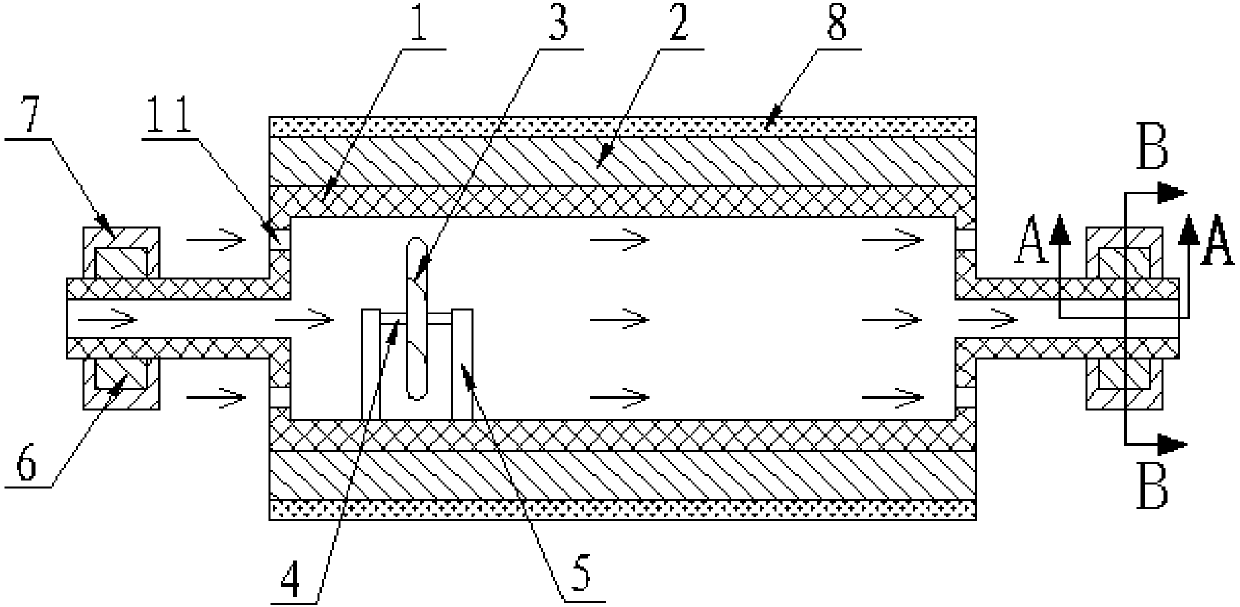

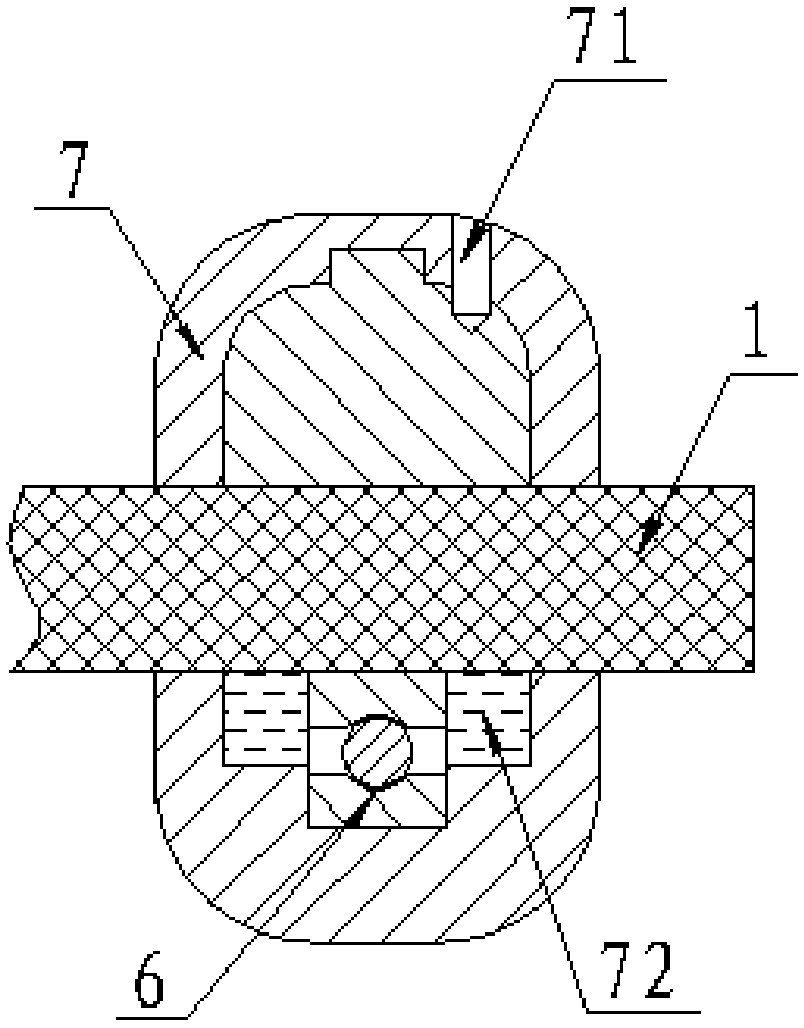

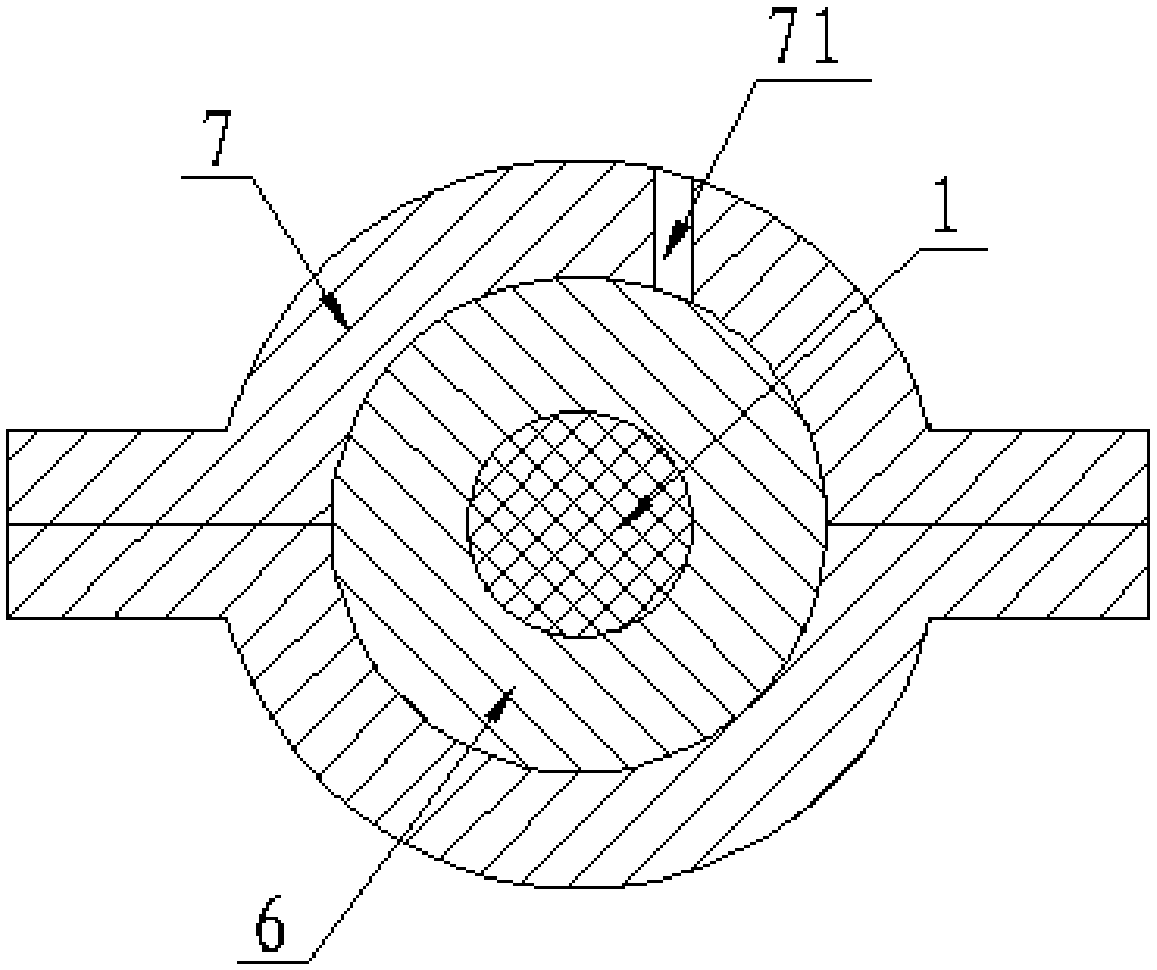

[0027] Embodiment 1: A kind of rapid heat dissipation anti-shedding rubber roller, such as Figure 1 ~ Figure 3 As shown, it includes a roller core 1, a rubber layer 2, an impeller 3, an impeller shaft 4, a mounting seat 5, a roller core bearing 6 and a bearing seat 7, and the rubber layer 2 is fixedly installed on the outer surface of the roller core 1, and the roller core The middle section of 1 is a hollow roller, the impeller 3 is fixedly set on the impeller shaft 4, the two ends of the impeller shaft 4 are fixedly installed on the mounting seat 5, and the mounting seat 5 is fixedly installed in the inner cavity of the roller core 1, and the impeller 3 is fixed along the roller The core 1 rotates in the circumferential direction, and there is a gap between the two top ends of the impeller 3 and the inner cavity of the roller core 1. A circular through hole 11, the through hole diameter is 1 centimeter, the through hole 11 communicates with the inner cavity of the roll core...

Embodiment 2

[0028] Embodiment 2: The difference with Embodiment 1 is that, as Figure 4 As shown, the outer surface of the roller core 1 is equidistantly arranged in the axial direction with six overall annular anti-slip grooves 12 whose longitudinal cross-sectional shape is rectangular.

Embodiment 3

[0029] Embodiment 3: The difference with Embodiment 2 is that, as Figure 5 As shown, the through hole 11 is a heat dissipation hole with a slope of 45 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com