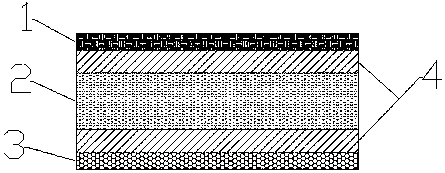

Impervious geosynthetic clay liner

A technology of bentonite waterproof blanket and bentonite, applied in geotextiles, water conservancy projects, protective devices, etc., can solve the problems of poor impermeability and other problems, and achieve the effects of good viscosity and elasticity, good bonding, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026]Pour sodium-based bentonite into a pulverizer, and pass through a 325-mesh sieve after crushing to obtain sodium-based bentonite powder. Mix 10% sulfuric acid solution with a mass fraction of 8% hydrochloric acid at a volume ratio of 1:3 to obtain a mixed acid solution , and then mix the sodium-based bentonite powder and the mixed acid solution according to the mass ratio of 1:30 and pour them into the reaction kettle. Under the conditions of temperature of 55°C and rotation speed of 600r / min, stir and react at a constant temperature for 4 hours, and filter to obtain a filter cake. And wash the filter cake with deionized water until the washing liquid is neutral, then transfer the washed filter cake to an oven, and dry it to a constant weight at a temperature of 110°C to obtain acid-leached bentonite, and then mix the acid-leached bentonite with the mass The fraction of 10% silver nitrate solution is mixed according to the mass ratio of 1:50 and poured into the beaker, an...

example 2

[0028] Pour sodium-based bentonite into a pulverizer, and pass through a 325-mesh sieve after crushing to obtain sodium-based bentonite powder. Mix 10% sulfuric acid solution with a mass fraction of 8% hydrochloric acid at a volume ratio of 1:3 to obtain a mixed acid solution , and then mix the sodium-based bentonite powder and the mixed acid solution according to the mass ratio of 1:30 and pour them into the reaction kettle. Under the conditions of temperature of 55°C and rotation speed of 600r / min, stir and react at a constant temperature for 4 hours, and filter to obtain a filter cake. And wash the filter cake with deionized water until the washing liquid is neutral, then transfer the washed filter cake to an oven, and dry it to a constant weight at a temperature of 110°C to obtain acid-leached bentonite, and then mix the acid-leached bentonite with the mass The fraction of 10% silver nitrate solution is mixed according to the mass ratio of 1:50 and poured into the beaker, a...

example 3

[0030] Then in parts by weight, successively take 100 parts of sodium bentonite, 20 parts of binder, and 40 parts of water, stir and mix with a mixer at a speed of 800 r / min for 60 minutes to obtain a bentonite mixture, and then transfer the bentonite mixture to vacuum kneading Extruder, after vacuum kneading for 30 minutes, extrude to obtain a bentonite layer; pour agar, gluten powder and water into a beaker with a mass ratio of 10:3:100, stir and mix with a glass rod for 20 minutes, and let it stand for swelling 4h, then move the beaker into a digital speed measuring constant temperature magnetic stirrer, at a temperature of 95°C and a speed of 400r / min, stir and dissolve at a constant temperature for 5h, then cool naturally to room temperature to obtain a mixed solution; Take 30 parts of the mixed solution preheated to 80°C and 80 parts of the organic solvent at the temperature of 25°C, and spray the mixed solution into the beaker containing the organic solvent through the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com