Pneumatic expanding machine for 3D printing garment blank

A 3D printing and pneumatic technology, applied in the field of clothing production, can solve the problems of heavy weight, small elasticity, and low wearing comfort, and achieve the effect of improving elasticity and flexibility, improving elasticity and flexibility, and improving quality and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

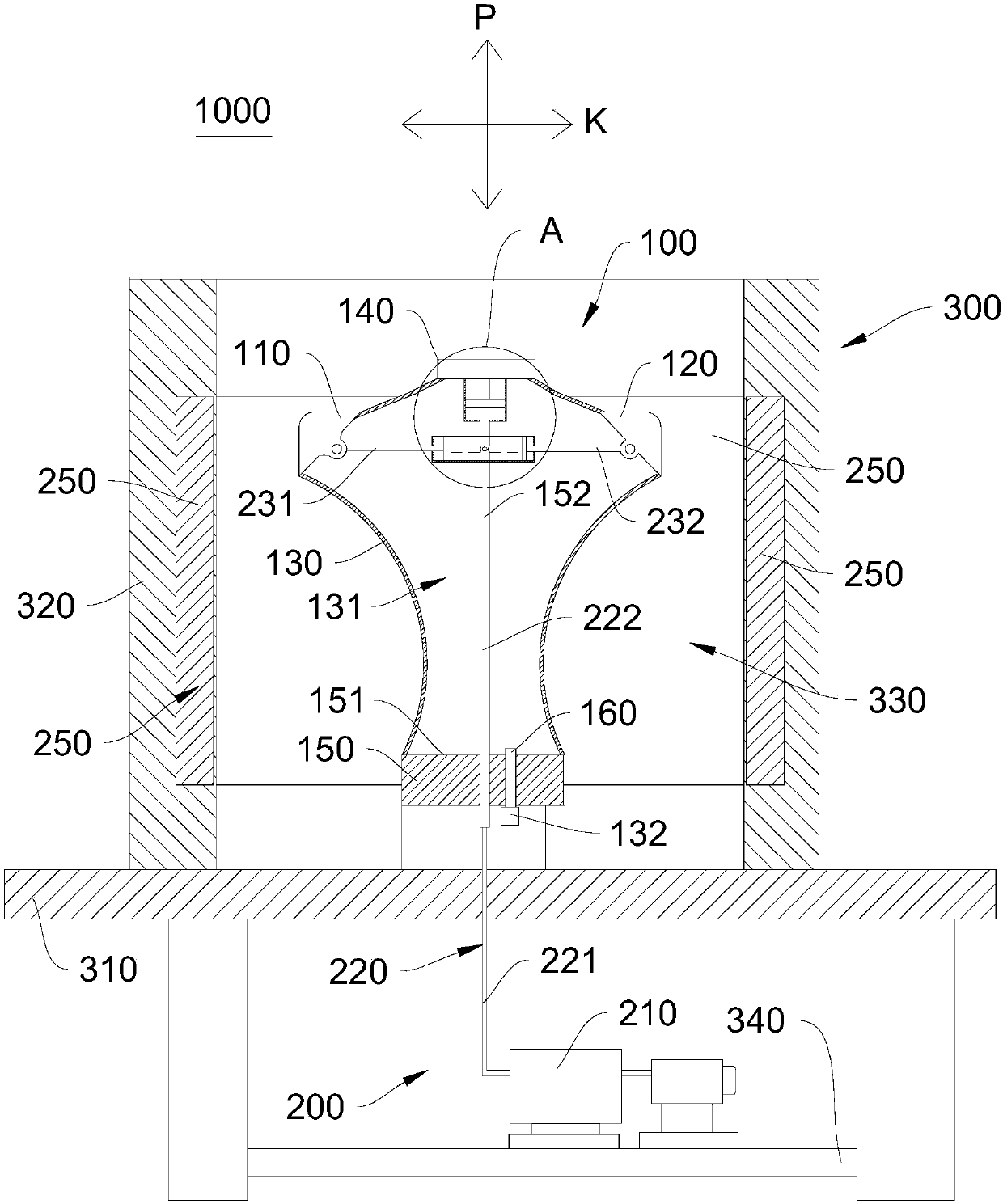

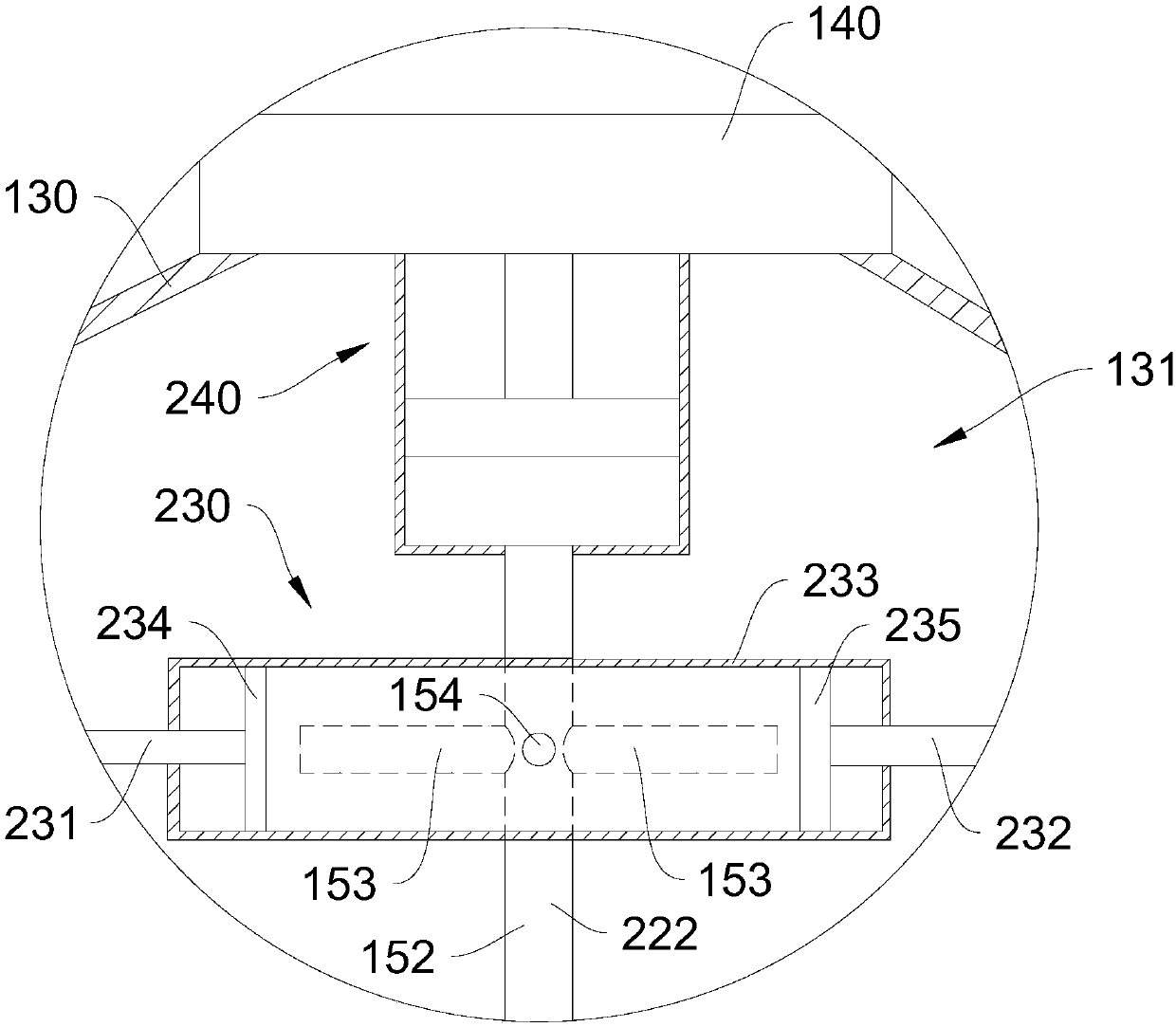

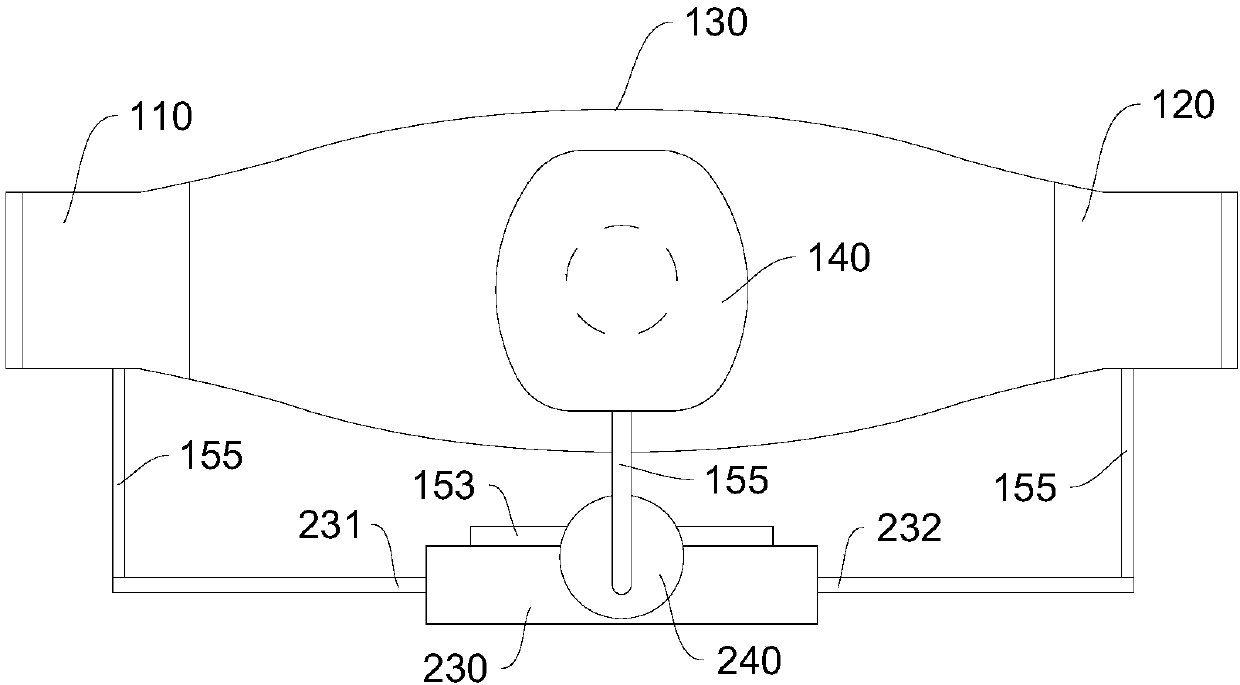

[0033] Please refer to Figure 1~2 , the present embodiment provides a 3D printed garment blank pneumatic stretching machine 1000. The 3D printed garment blank pneumatic stretching machine 1000 includes: an elastic mannequin 100, a drive assembly 200 and a device for heating the garment blank located on the elastic mannequin 100 Heater 250. The elastic mannequin 100 includes a first shoulder rest 110, a second shoulder rest 120 and a phantom body 130 made of elastic material. The driving assembly 200 includes an air pump 210 , an air delivery pipe 220 and a shoulder cylinder 230 .

[0034]The phantom body 130 has a cavity 131 for inflating air and an exhaust valve 132 for exhausting the cavity 131 . The first shoulder rest 110 and the second shoulder rest 120 are respectively connected to two shoulders of the phantom body 130 . The shoulder rest cylinder 230 includes a first piston rod 231 and a second piston rod 232 , the first shoulder rest 110 is connected to the first pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com