Machine and method for automatic feeding and bending

A feeding and bending technology, which is applied in the field of automatic feeding and bending, can solve the problems of high cost, cumbersome processing technology, and low yield rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

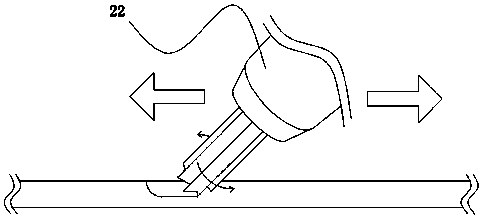

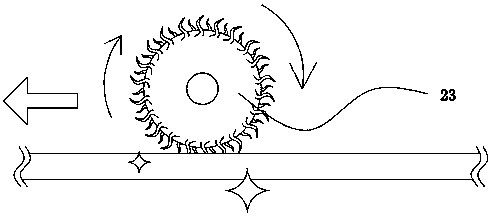

[0093] Combine below Figure 1 to Figure 28 , the present invention is further described:

[0094] The invention relates to an automatic feeding and bending method and mechanical equipment for automatic production of frame products. The automatic feeding and bending technology integrates the following processes and their flow sequences.

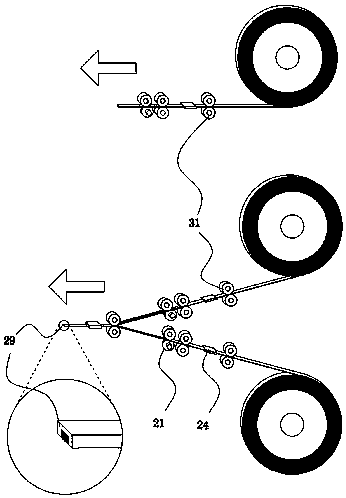

[0095] like figure 1 As shown, S1. Material preparation stage: the function of this material preparation stage is to straighten the materials, which can be continuous coils or fixed-length strips. Straightening equipment includes rollers, pipes, belts or levelers.

[0096] The single material is straightened by rollers, pipes, belts, and levelers, and the continuous straight material or coil is straightened, and it is supplied to the direction of the machine tool in the S2. material forming stage. The material is driven forward through the driving wheel 31 .

[0097] In addition, when a plurality of materials are added according to the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com