Baking method of dried fishes

A technology of fish drying and drying chamber, which is applied in the field of aquatic product drying technology, which can solve the problems of losing flavor, easy breakage, and affecting the shape of dried fish, so as to avoid high-temperature scorching of fish and save energy and equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further detailed explanation through specific implementation mode below:

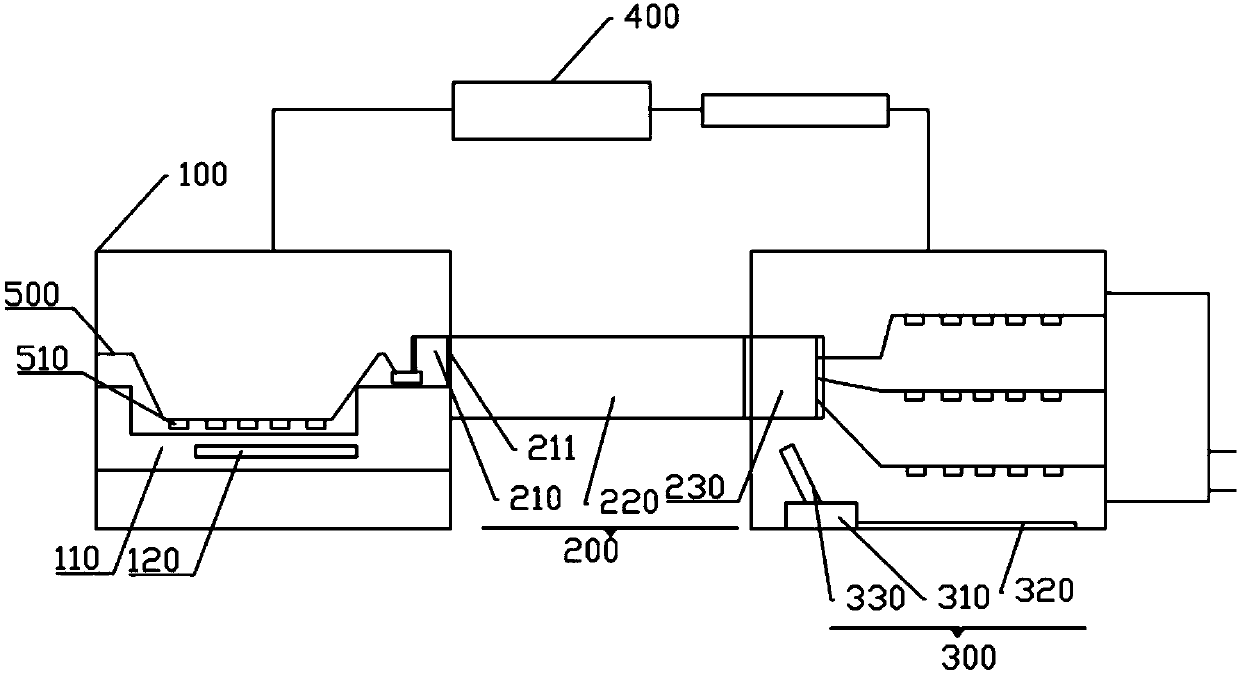

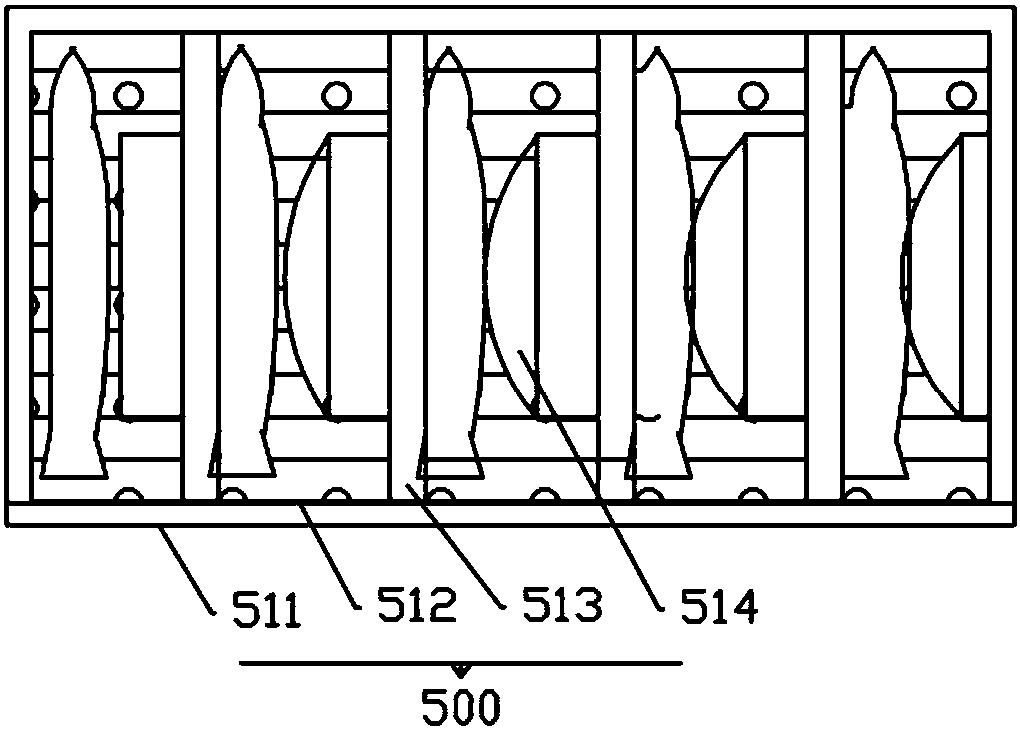

[0027] The reference signs in the drawings of the description include: high-pressure cooking chamber 100, boiling pool 110, heater 120, communication chamber 200, high-pressure transition room 210, sealing valve 211, normal-pressure operating room 220, low-pressure transition room 230, low-pressure transition room 230, low-pressure Drying chamber 300 , internal circulation pump 310 , dryer 320 , low temperature heater 330 , high pressure pump 400 , transport system 500 , transport frame 510 , frame 511 , breathable net 512 , partition 513 , elastic block 514 .

[0028] Example using attached figure 1 The drying room shown is implemented: comprising a high-pressure cooking chamber 100, a communication chamber 200, a high-pressure pump 400, and a low-pressure drying chamber 300, and a transport system 500 for transporting dried fish from the high-pressure cooking chamber 100 to the low-pressure dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com