Cotton harvester

A cotton harvesting and transmission box technology, which is applied to harvesters, agricultural machinery and implements, pickers, etc., can solve the problems of low service life and harsh environment of harvesters, and achieve long service life, good rigidity and stable lifting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

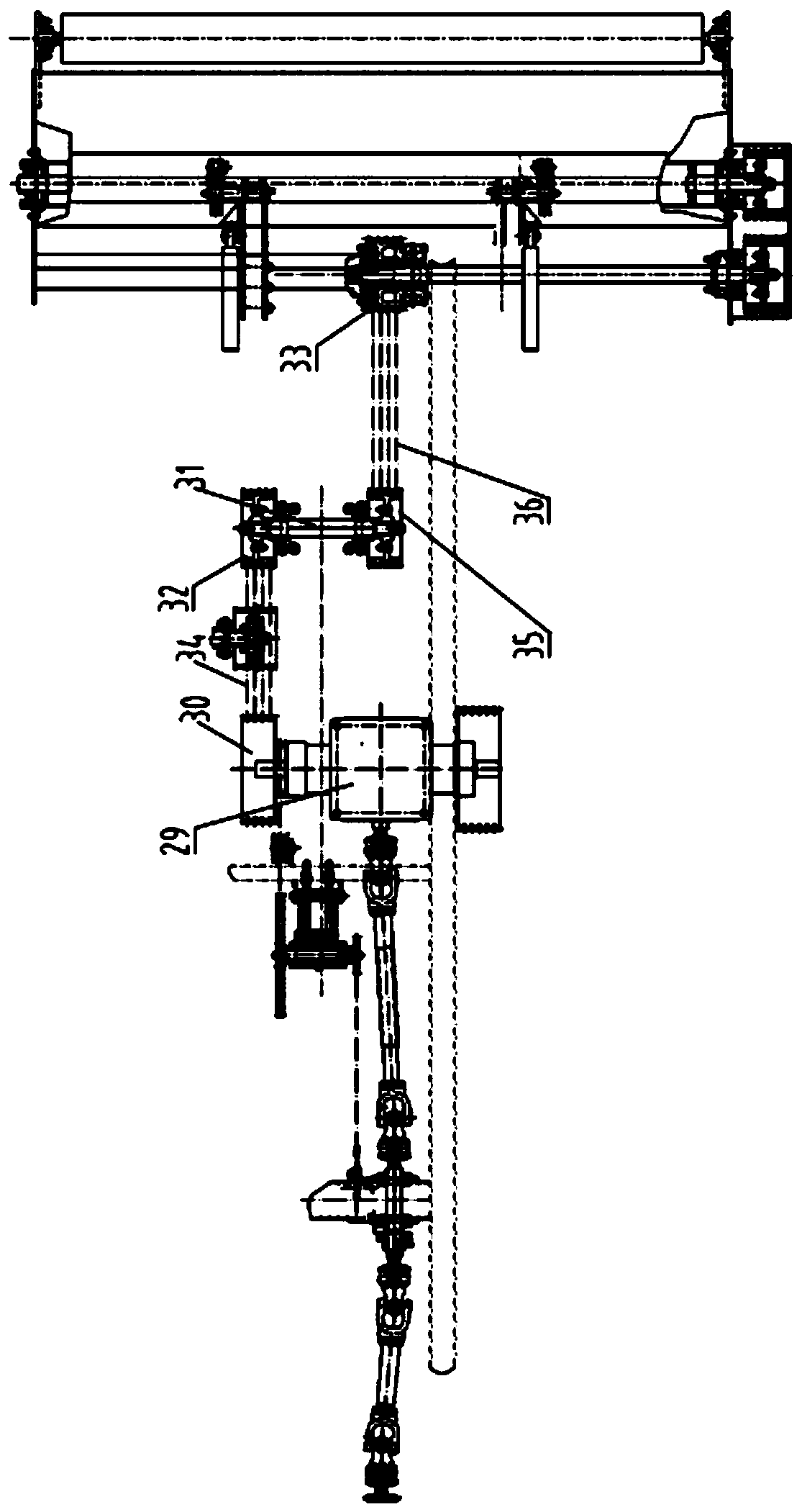

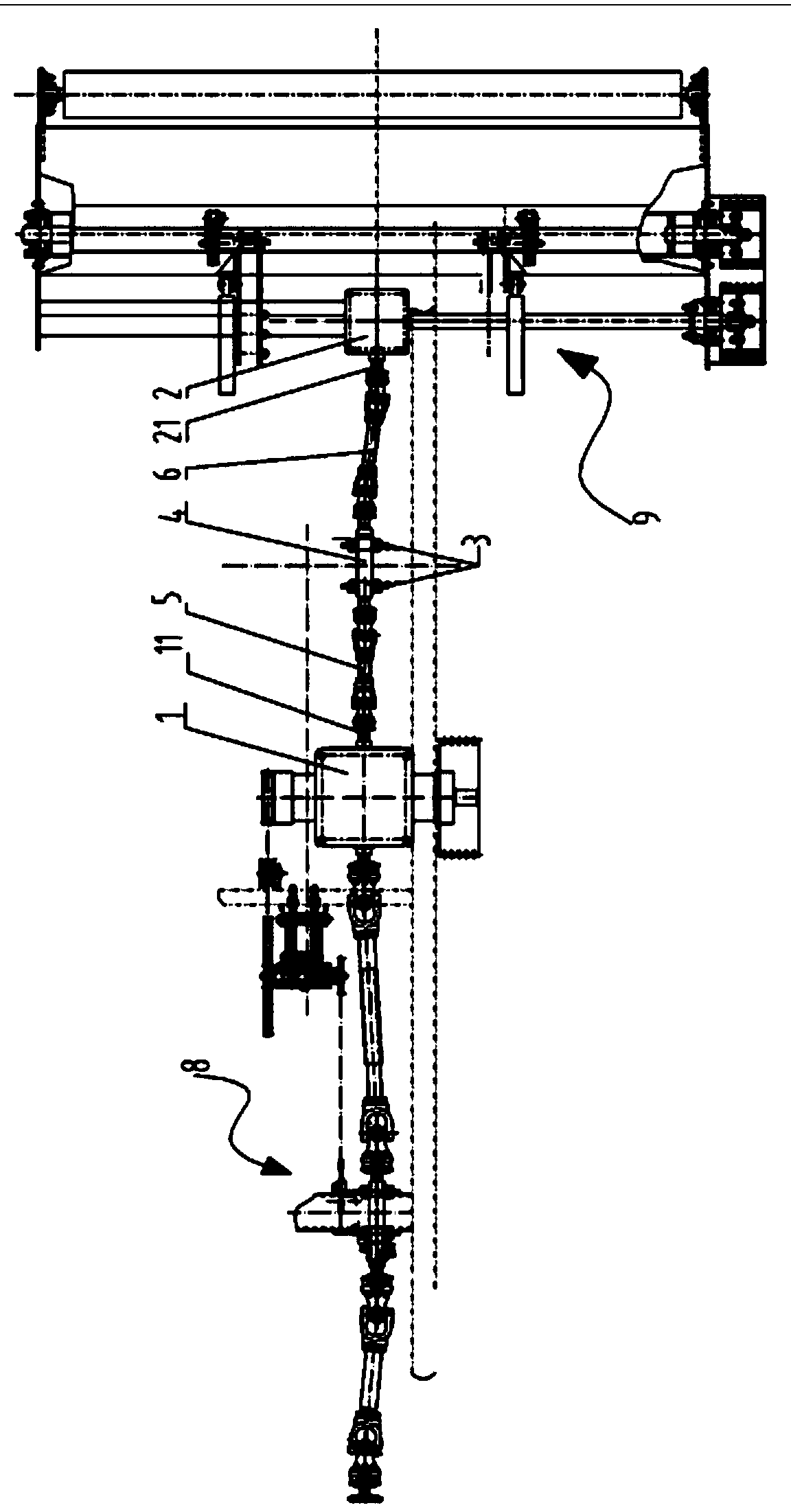

[0012] Examples of cotton harvesters, such as figure 2 As shown, it includes a transmission box 1 that transmits driving force to the chopper, and is arranged on the chopper to transmit the power input from the transmission box to the reversing box 2 of the chopper. The rear end of the transmission box 1 is provided with a The output shaft 11 of the transmission box connected by transmission, the front end of the reversing box 2 is provided with the output shaft 21 of the reversing box connected with the reversing transmission of the chopper, the position between the transmission box 1 and the reversing box 2 is horizontal through the support 3 The transition shaft 4 is installed in rotation, and the first universal joint transmission shaft 5 is connected between the transmission box output shaft 11 and the front end of the transition shaft 4. The first universal joint transmission shaft 5 is a telescopic universal joint transmission shaft, and the transition shaft A second u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com