Modular split assembled axial flow fan impeller and assembling method thereof

A fan impeller and axial flow technology, which is applied to the components of pumping devices for elastic fluids, liquid fuel engines, mechanical equipment, etc., can solve the problems of increasing the production cost of the user, blade deformation or breakage, waste, etc. Achieve the effects of improving stability and safety, reducing axial wind noise and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

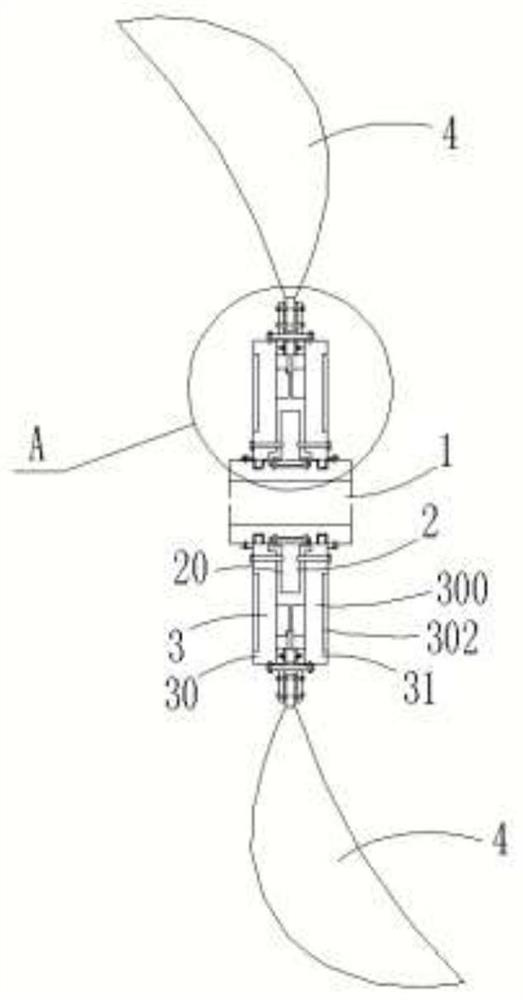

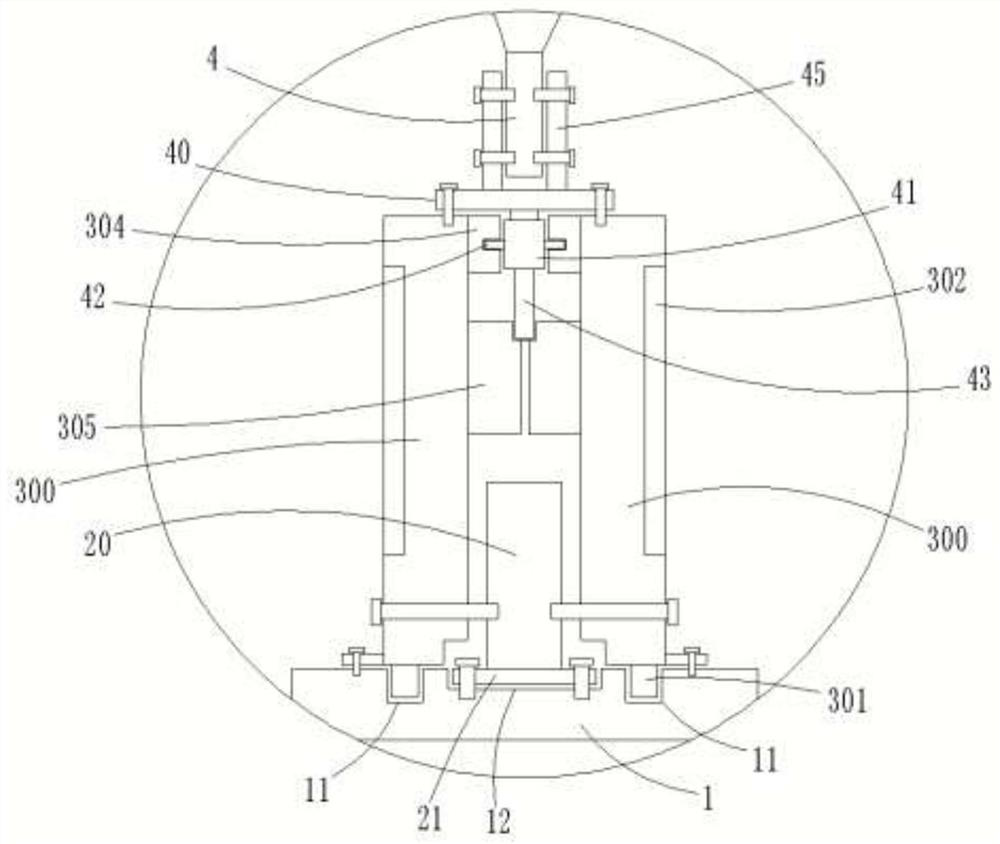

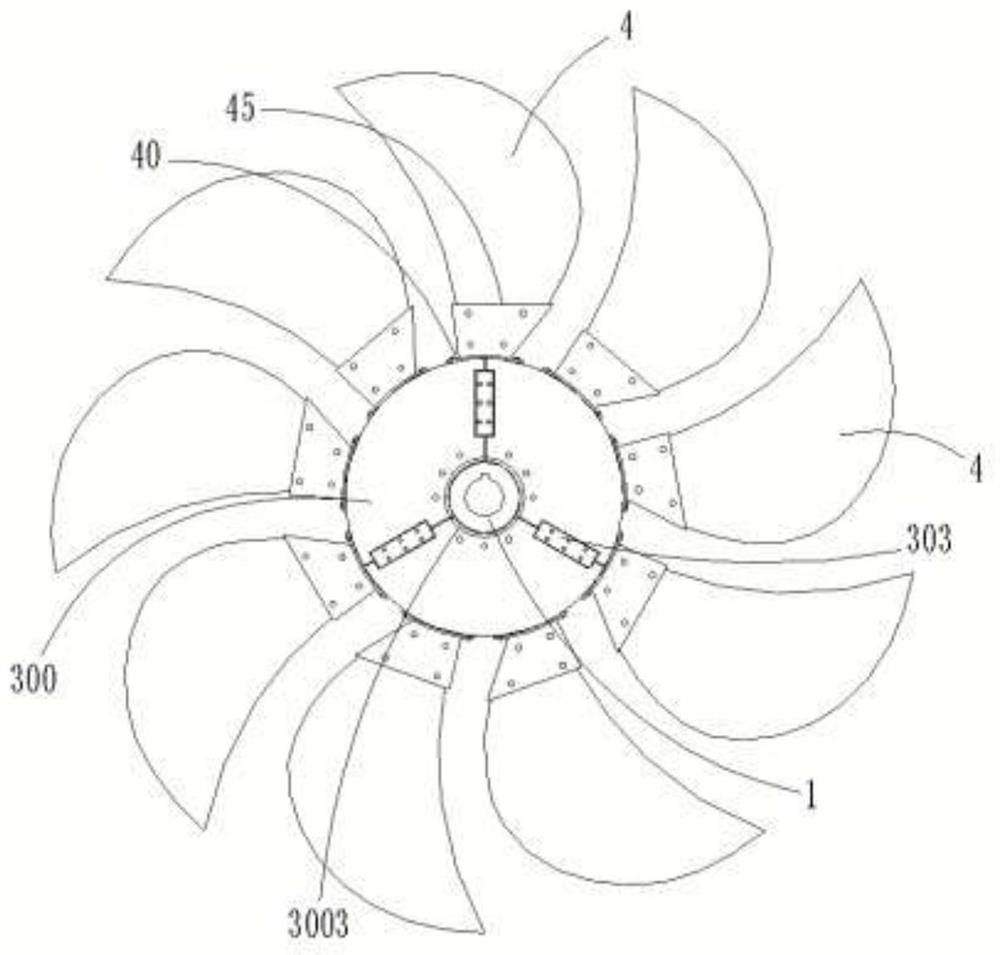

[0033] Example: such as figure 1 , 4 A modular split-assembled axial-flow fan impeller shown includes a mounting sleeve 1, a hub 2, a disc 3 and blades 4; the mounting sleeve 1 is axially provided with a keyway 10, and the outer wall is provided with a A limiting groove 11 and a second limiting groove 12, the first limiting groove 11 is provided with two groups, each group is provided with 3 pieces, and the two ends of the installation sleeve 1 are distributed in a ring, the number of the second limiting groove 12 It corresponds to the first limiting groove 11 and is located between two groups of first limiting grooves 11;

[0034] Such as figure 2 , 5 As shown, the hub 2 is spliced by three wheel petals 20, and the inner side of each wheel petal 20 is provided with a first installation arc plate 21, and each wheel petal 20 passes through the first installation arc plate 21 and each second limiting groove respectively. 12 installation and fixing;

[0035] Such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com