Plugging head for effectively preventing oil leakage of high voltage breaker hydraulic mechanism and manufacturing method thereof

A technology for high-voltage circuit breakers and hydraulic mechanisms, applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problems of increased oil leakage of hydraulic mechanisms, failure to block oil nozzles, etc., and achieve enhanced sealing effect and easy installation and disassembly Simple and avoid the effect of poor airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

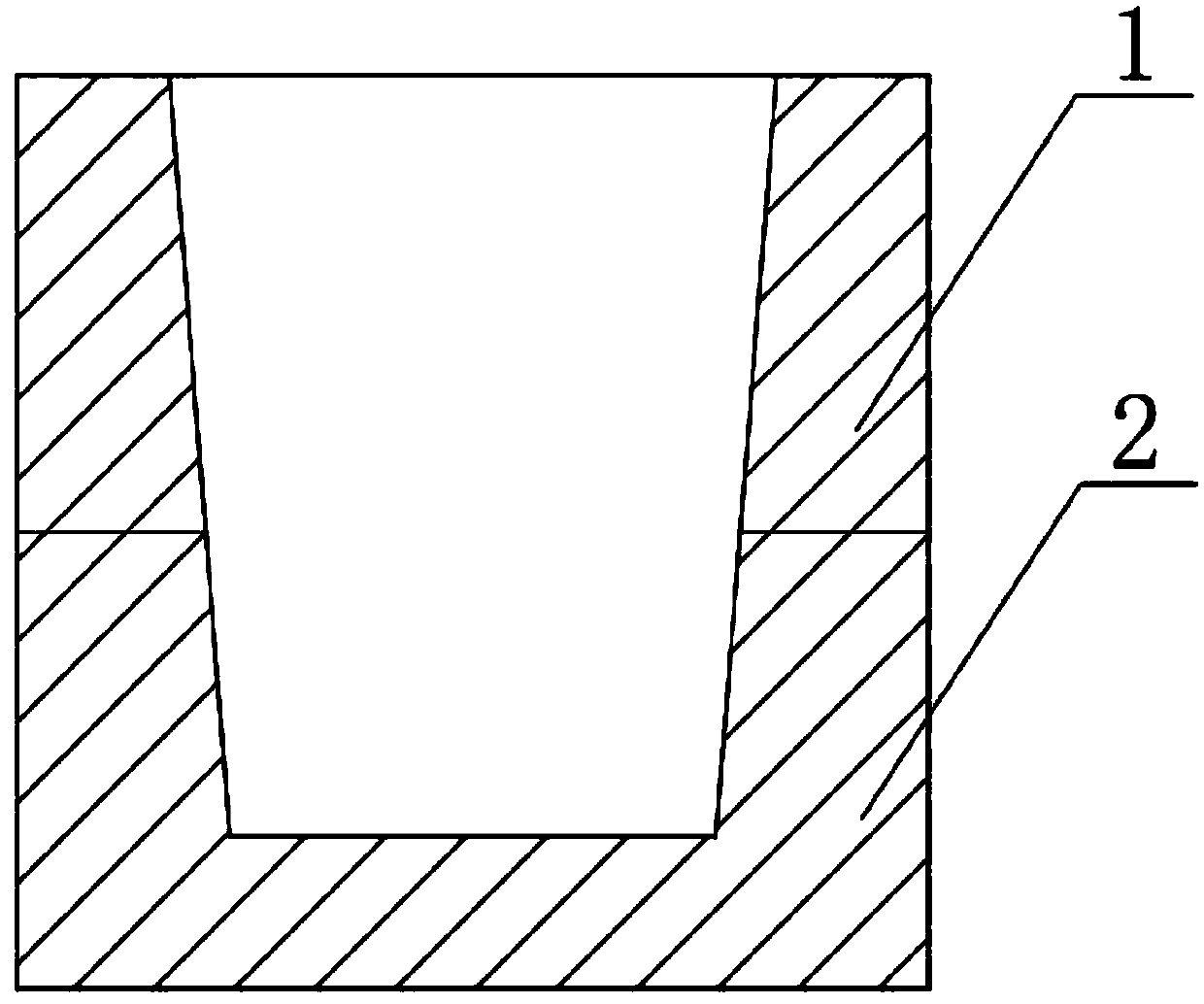

[0017] Combine figure 1 To explain this embodiment, the plugging head described in this embodiment that effectively prevents oil leakage of the hydraulic mechanism of a high-voltage circuit breaker includes a tightening portion 1, a plugging portion 2 and a locking mechanism 3. At present, the hydraulic The oil leakage of the mechanism is generally not plugged or simply use a tube and seal the bottom end.

[0018] The tightening part 1 and the sealing part 2 are both hollow cylindrical, and the bottom surface of the sealing part 2 is closed, the tightening part 1 is coaxially fixed above the sealing part 2, and the tightening part 1 and the sealing part 2 The inner diameter gradually decreases from the top of the tightening portion 1; the locking mechanism 3 wraps around and tightens the outer wall of the tightening portion 1.

[0019] The tightening part 1 and the blocking part 2 constitute an elastic rubber sleeve, which can be sleeved on the end of the oil pipe of the hydraulic ...

specific Embodiment approach 2

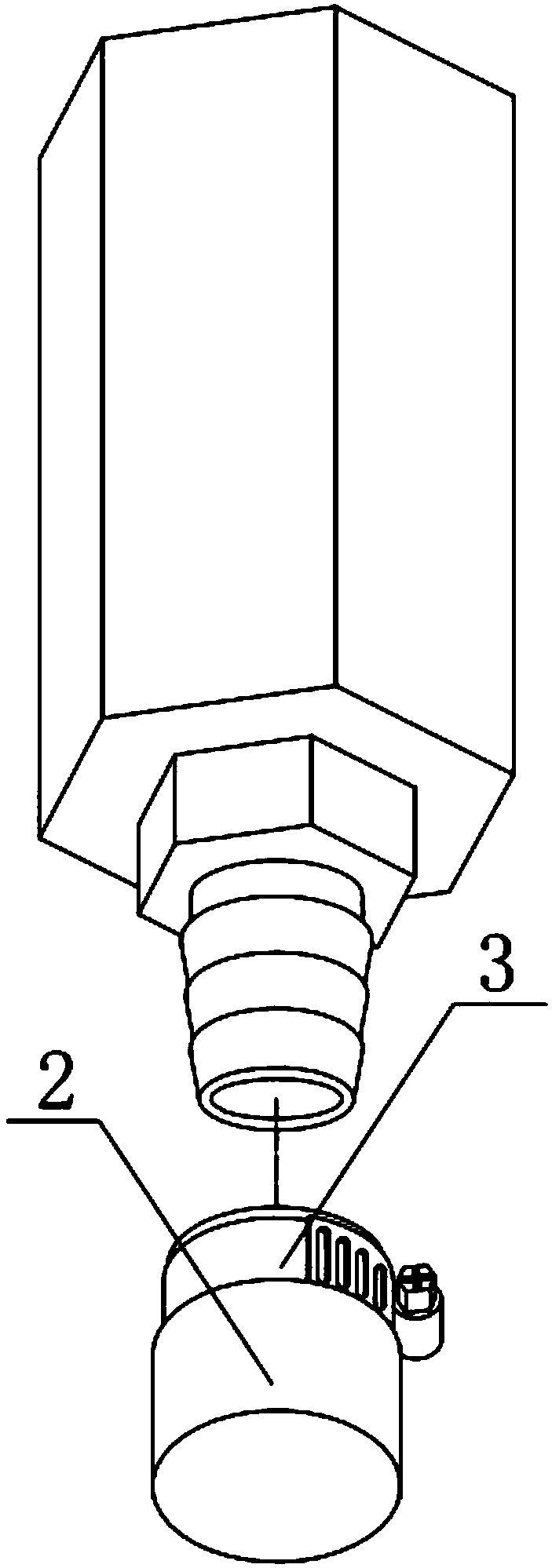

[0020] Combine figure 2 with image 3 To illustrate this embodiment, the difference between the second embodiment and the first embodiment is that there are stepped concave-convex ribs 16 from top to bottom along the inner walls of the tightening portion 1 and the blocking portion 2, due to the oil nozzle of the high-voltage circuit breaker Such as image 3 As shown, the outer wall is a multi-layer stepped round tube, so the stepped concave-convex rib 16 matching the outer wall of the oil nozzle is added to the inner wall of this embodiment, which can be more firmly sleeved on it, so that the sealing effect is better. It can further prevent the locking mechanism 3 from falling immediately and losing the blocking effect due to the damage of the locking mechanism 3, and the matched structure ensures that the staff can discover the impending failure of the blocking in time, and take repair and replacement operations.

specific Embodiment approach 3

[0021] Combine figure 2 , image 3 with Figure 4 Explaining this embodiment, the difference between this embodiment 3 and embodiment 1 or embodiment 2 is that the outer diameter of the tightening portion 1 is smaller than the outer diameter of the blocking portion 2, even if the outer diameter of the tightening portion 1 is made during manufacturing. The diameter is smaller than the outer diameter of the blocking part 2, and there is no difficulty in manufacturing technology, but it can not only save more costs, but also make the locking mechanism 3 easier to get stuck in the position of the tightening part 1, preventing The string moves and falls off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com