Enrichment method of ores containing cobalt and nickel

A cobalt ore and enrichment technology is applied to enrich cobalt and nickel in cobalt and nickel ore materials to a higher grade field, which can solve the problems of high energy consumption and low selection rate, and achieve low energy consumption, The effect of reducing energy consumption and improving the enrichment selection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 - is the method that the raw ore containing cobalt 4.01% carries out enrichment treatment:

[0025] The steps in this method are:

[0026] 1. First crush the cobalt-containing ore to less than 30mm;

[0027] 2. Then the crushed cobalt-containing ore is reduced;

[0028] 3. The reduced cobalt-containing ore is crushed to a particle size of less than 80 mesh;

[0029] 4. After magnetic separation by a magnetic separator with a magnetic field strength of 5000 gauss, cobalt concentrate powder with a cobalt content of 31.52% was obtained, and the cobalt recovery rate was 94%.

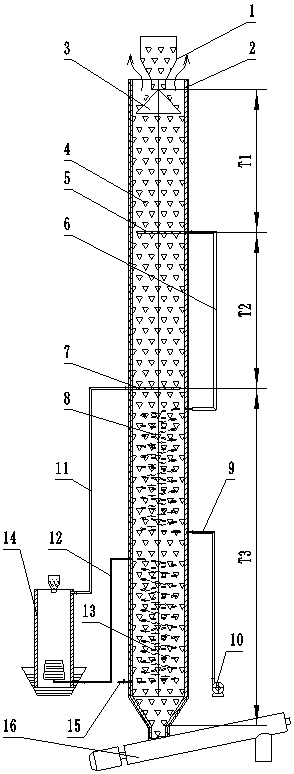

[0030] The above-mentioned reduction treatment is carried out in a reduction furnace with an upper mineral material inlet and a lower mineral material outlet. There is a feed hopper 1 at the upper end of the reduction furnace, and there is smoke between the feed hopper 1 and the furnace shell 2 of the reduction furnace. The gas outlet, the upper inlet of the feed hopper 1 is the or...

Embodiment 2

[0040] Embodiment 2---is the method that the raw ore containing nickel 1.2% carries out enrichment treatment:

[0041] The steps in this method are:

[0042] 1. First crush the nickel-containing ore to less than 30mm;

[0043] 2. Then the crushed cobalt-containing ore is reduced;

[0044] 3. The reduced nickel-containing ore is crushed to a particle size of less than 80 mesh;

[0045] 4. After magnetic separation by a magnetic separator with a magnetic field strength of 5000 gauss, the nickel concentrate powder with a nickel content of 3.5% is obtained, and the recovery rate of nickel is 90%.

[0046] In the reduction treatment of the nickel-containing ore in this embodiment, the other parts of the reduction treatment are exactly the same as in Example 1, except that the ore material is the raw ore containing 1.2% nickel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com