Sand mixing machine for casting

A sand mixer and sand mixing technology, applied in foundry molding equipment, machinery for cleaning/processing of mold materials, manufacturing tools, etc., can solve the problems of no heat dissipation structure, no cleaning structure, etc. Use the effect of sealing and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

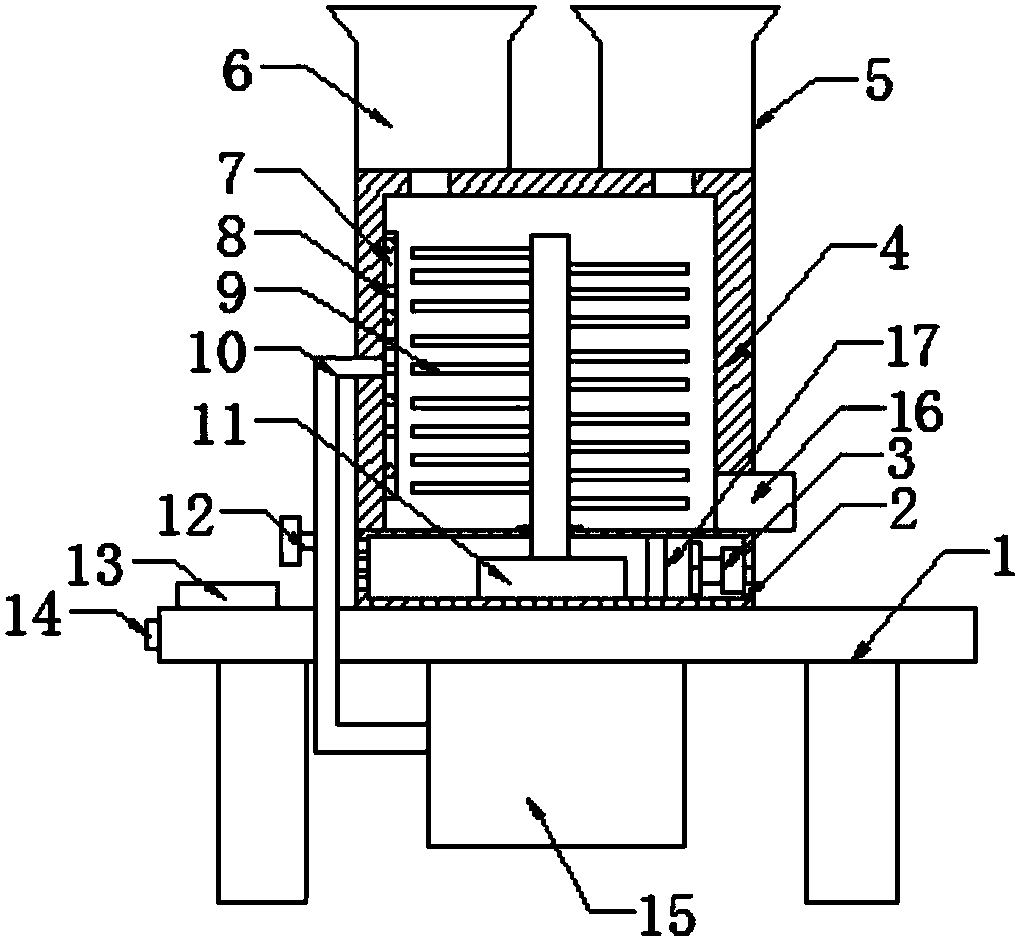

[0019] Specific implementation method: the staff pours new sand from the new sand bin 6, and pours the old sand from the old sand bin 5. The screen inside the new sand bin 6 screens the new sand, and the screen inside the old sand bin 5 screens the old sand. After screening, the new sand and old sand enter the sand mixing box 4 from the new sand bin 6 and the old sand bin 5, and the staff connects the rotating motor 11 to the battery 13, and the rotating motor 11 drives the stirring blade 9 to rotate through the stirring shaft, and the stirring blade 9 The new sand and the old sand are stirred quickly, and the cooling fan 3 and the semiconductor cooling sheet 17 are connected to the battery 13 after the rotating motor 11 has been working for a long time, and the cooling fan 3 and the semiconductor cooling sheet 17 start to work, and the cooling fan 3 blows cold air to the rotating motor 11 , the rotating motor 11 dissipates heat, and the inner wall of the inner cavity 2 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com