Multi-functional aluminum scrap smelting furnace

An aluminum smelting furnace and multi-functional technology, applied in the field of multi-functional waste aluminum smelting furnaces, can solve the problems of inconvenient disassembly and assembly of a single crystal furnace body, long time for disassembling or tightening screws, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

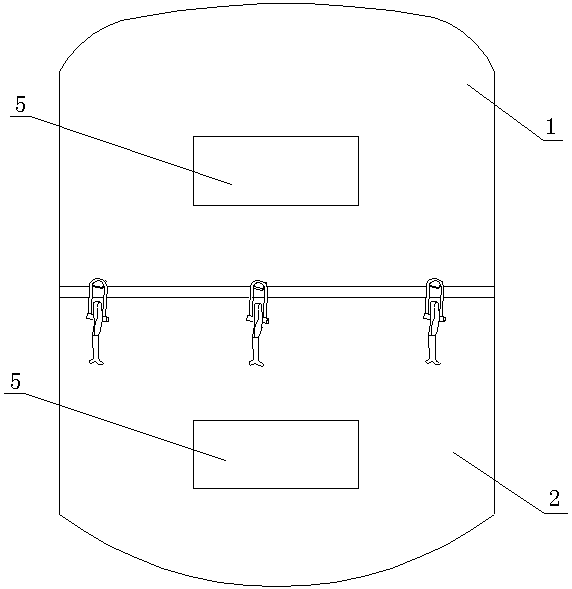

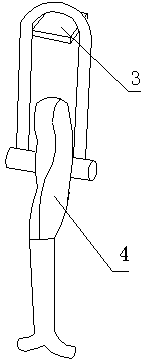

[0012] see figure 1 and figure 2 , a multifunctional scrap aluminum smelting furnace related to the present invention, comprising an upper furnace body 1 and a lower furnace body 2, a plurality of bumps 3 are arranged on the side wall of the lower part of the upper furnace body 1, and the upper part of the lower furnace body 2 There are several box buckles 4 on the side wall, the number of the box buckles 4 is the same as that of the bumps 3, and each box buckle 4 is located under the bumps 3, and the box buckles 4 are matched with the bumps 3 , when it is necessary to disassemble the upper furnace body 1 and the lower furnace body 2, it can be easily completed as long as the box buckle 4 is loosened or fastened, which improves the disassembly efficiency of the upper furnace body 1 and the lower furnace body 2. Both the furnace body 1 and the lower furnace body 2 are provided with an observation port 5, the observation port 5 can conveniently see the situation inside the sme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com