Self constant current LED lamp filament

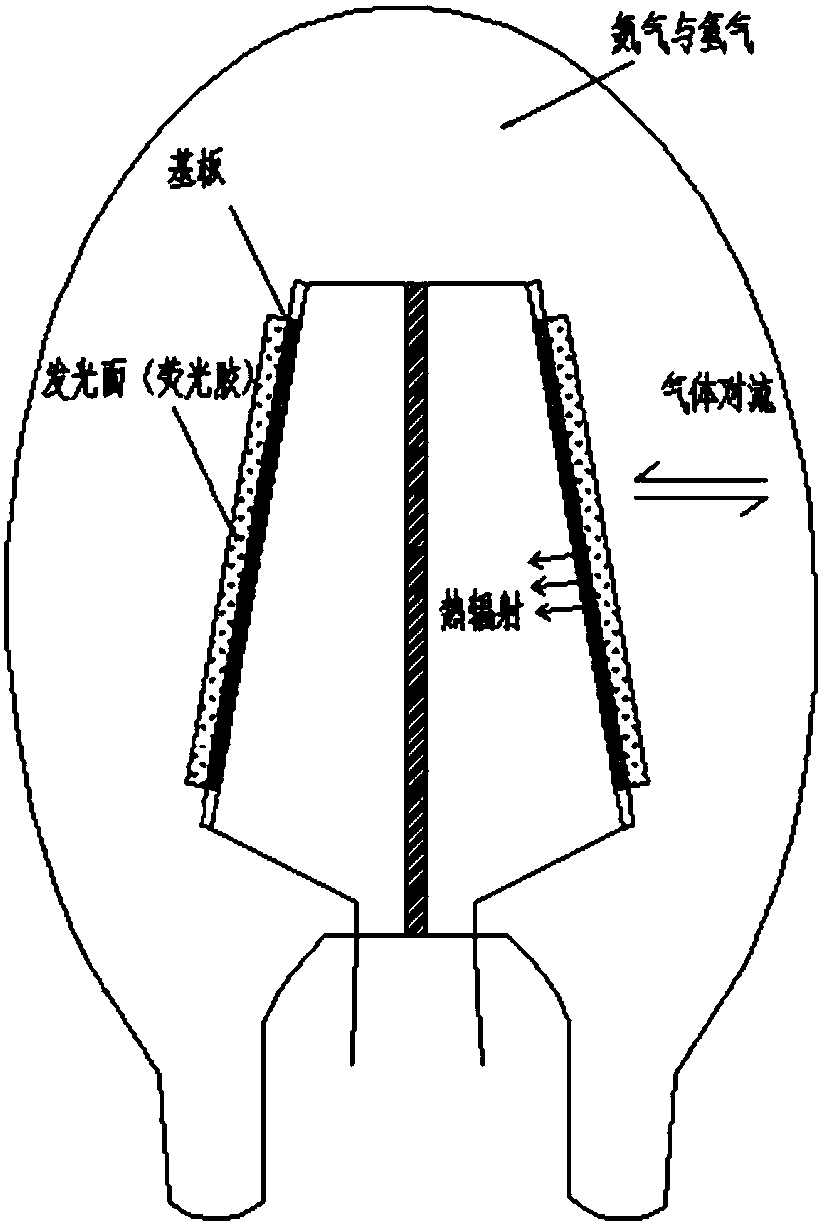

A technology for LED filaments and LED lamps, which is applied in the use of semiconductor lamps, cooling/heating devices of lighting devices, lighting and heating equipment, etc., can solve problems such as complex control structures, and achieve the effect of simplifying assembly processes and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

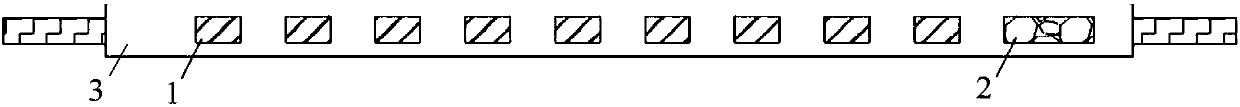

[0065] Such as figure 2 As shown, the present invention provides a self-constant current LED filament, and the self-constant current LED filament at least includes:

[0066] A plurality of LED lamps 1 , a constant current control chip 2 at both ends, a thermally conductive substrate 3 and a high-radiation material layer 4 .

[0067] Such as figure 2 As shown, each LED lamp 1 and the two-end constant current control chip 2 are fixed on the first surface of the heat-conducting substrate 3 .

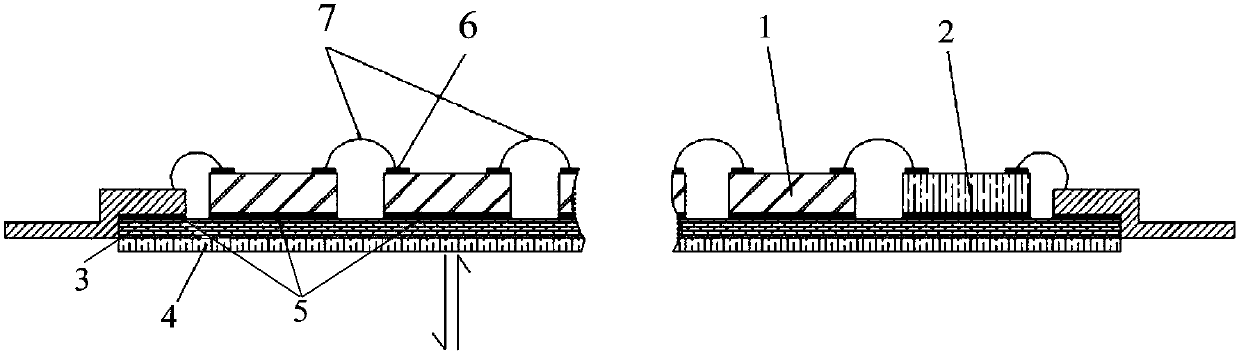

[0068] Specifically, as image 3 As shown, as an embodiment of the present invention, the LED lamp 1 is a front-mounted LED chip, and each front-mounted LED chip 1 and the constant current control chip 2 at both ends are fixed on the first side of the heat-conducting substrate 3 by an adhesive 5 . On the surface, a welding plate 6 is provided on the surface of each front-mounted LED chip 1 and the constant-current control chip 2 at both ends, and a plurality of front-mounted LED chips ...

Embodiment 2

[0087] The difference between this embodiment and the first embodiment is that the high-radiation material layer 4 is connected to the thermally conductive substrate 3 through chemical bonds, and the chemical bonds include but not limited to metal bonds, ionic bonds, and covalent bonds. In this embodiment, the material of the high-radiation material layer 4 includes but not limited to Nichrome, Nichrome oxide, Nichrome oxide, iron oxide, nickel oxide, bronze, cast iron , white ceramics, copper oxides, lead oxides, steel, steel oxides or aluminum oxides. Any material with a high thermal emissivity that can be formed by mechanical processing or chemical or physical processes and that is chemically bonded to the thermally conductive substrate 3 is suitable for the high-radiation material layer 4 of the present invention, and will not be listed here. .

[0088] Specifically, the formation method of the high radiation material layer 4 includes but not limited to gas phase surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com