Non-electric pulse type sewage lifting pump

A sewage lifting pump and pulse technology, which is applied in the field of non-electric pulse sewage lifting pumps, can solve the problems of sludge floating in sedimentation tanks, difficult construction, and inconvenient sludge discharge, so as to increase the sewage suction capacity and increase the scope of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

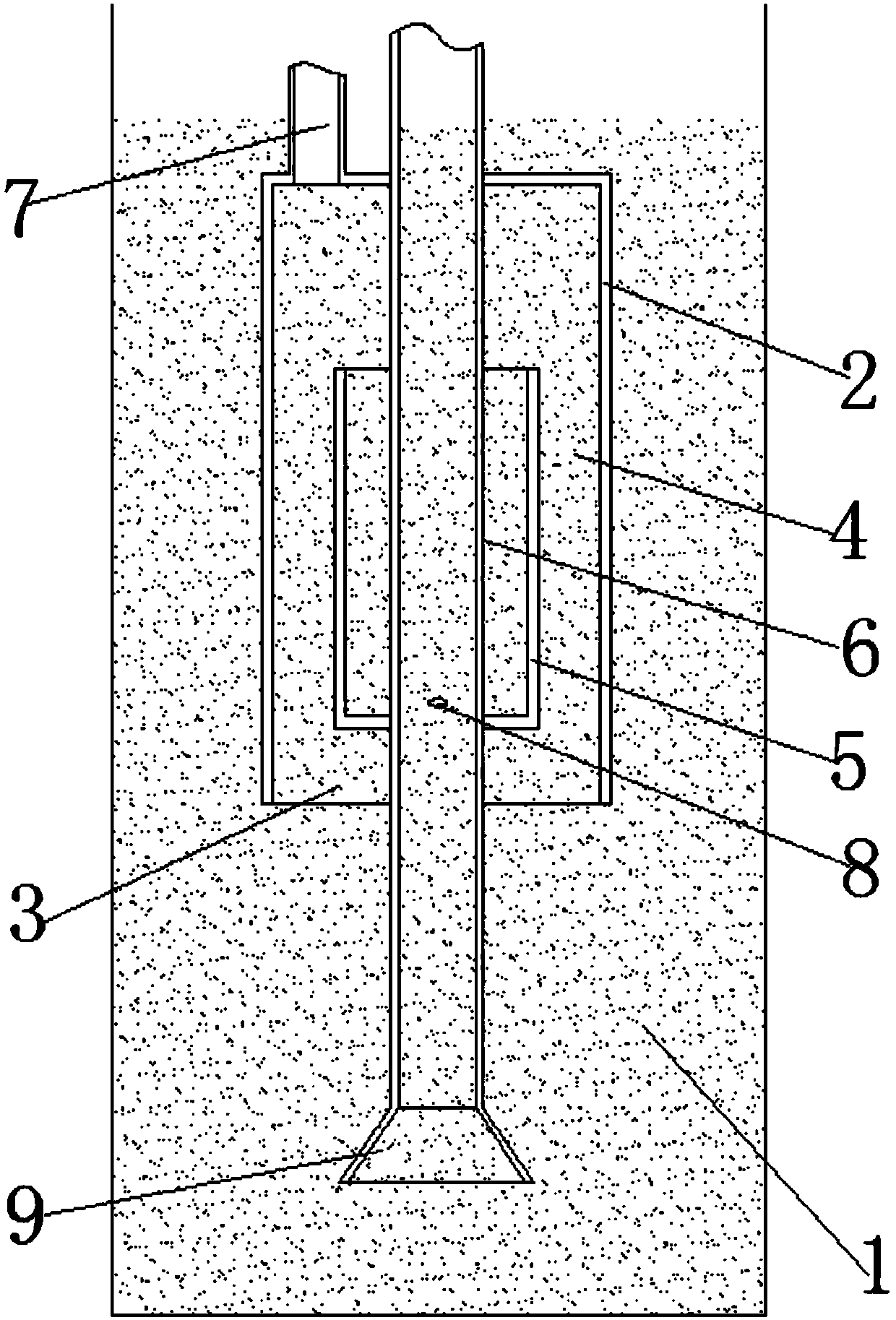

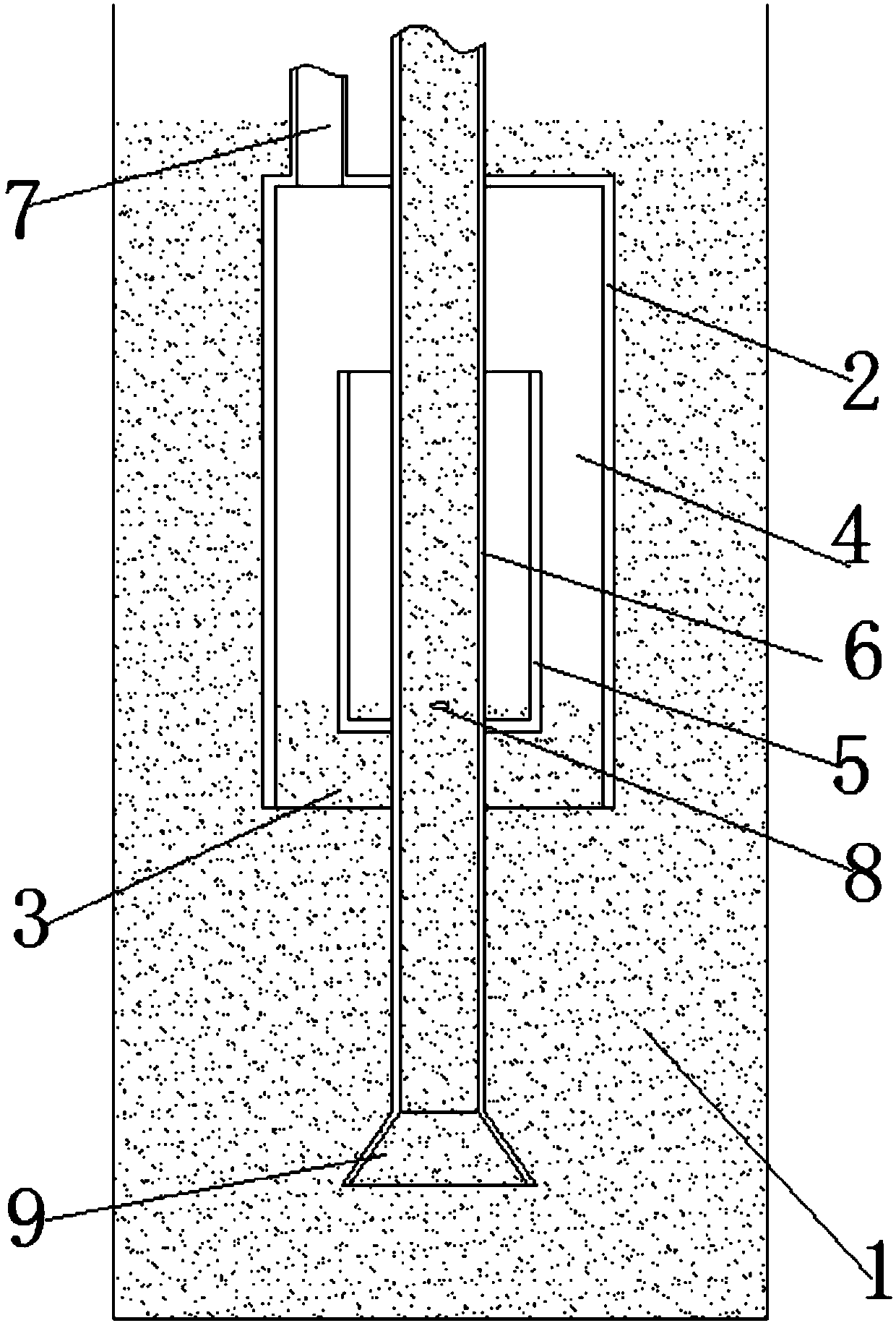

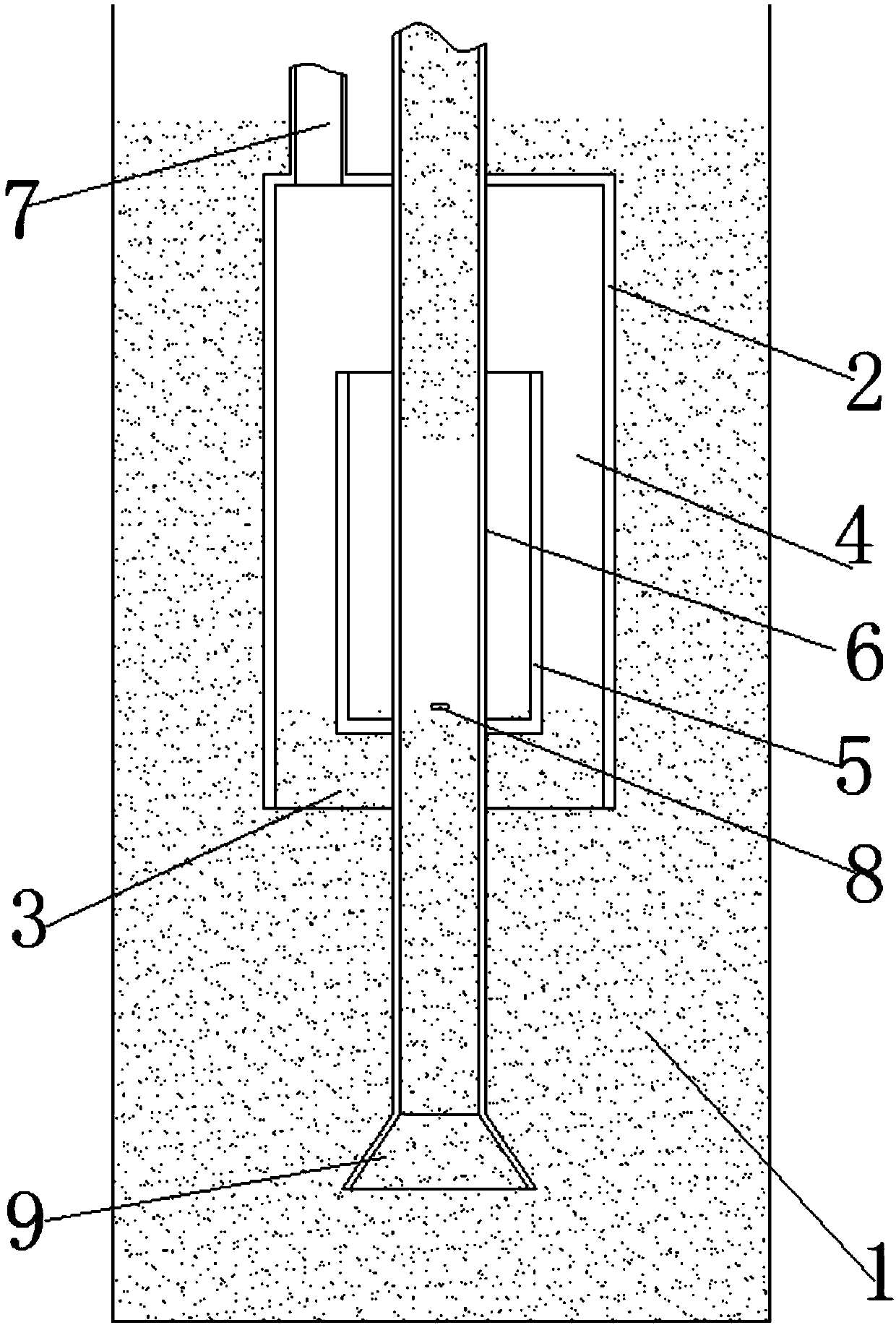

[0021] Such as figure 1 It is a schematic diagram of the structure of the non-electric pulse sewage lifting pump of the present invention before starting; the invention discloses a non-electric pulse sewage lifting pump, which includes a pump body 2 for setting below the liquid level of the sewage pool 1 and a pump body 2 protruding from the top of the sewage pool. The lift pipe 6 of the pool 1, the pump body 2 is provided with an atmospheric chamber 4 with an open bottom, a small air chamber 5 set in the large chamber 4 and with an open top, and the small air chamber 5 communicates with the large chamber 4 through the top opening, so The top of the pump body 2 is provided with an air inlet pipe 7 communicating with the large air chamber and the small air chamber, the riser 6 is set in the large air chamber 4 and the small air chamber 5 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com