Steel platform and construction method thereof

A construction method and steel platform technology, which is applied in the direction of construction, building structure, and construction materials, can solve the problems of high cost of foundation pit support measures, serious waste of demolition pollution, and deterioration of surrounding traffic conditions. Convenience, good mechanical performance, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

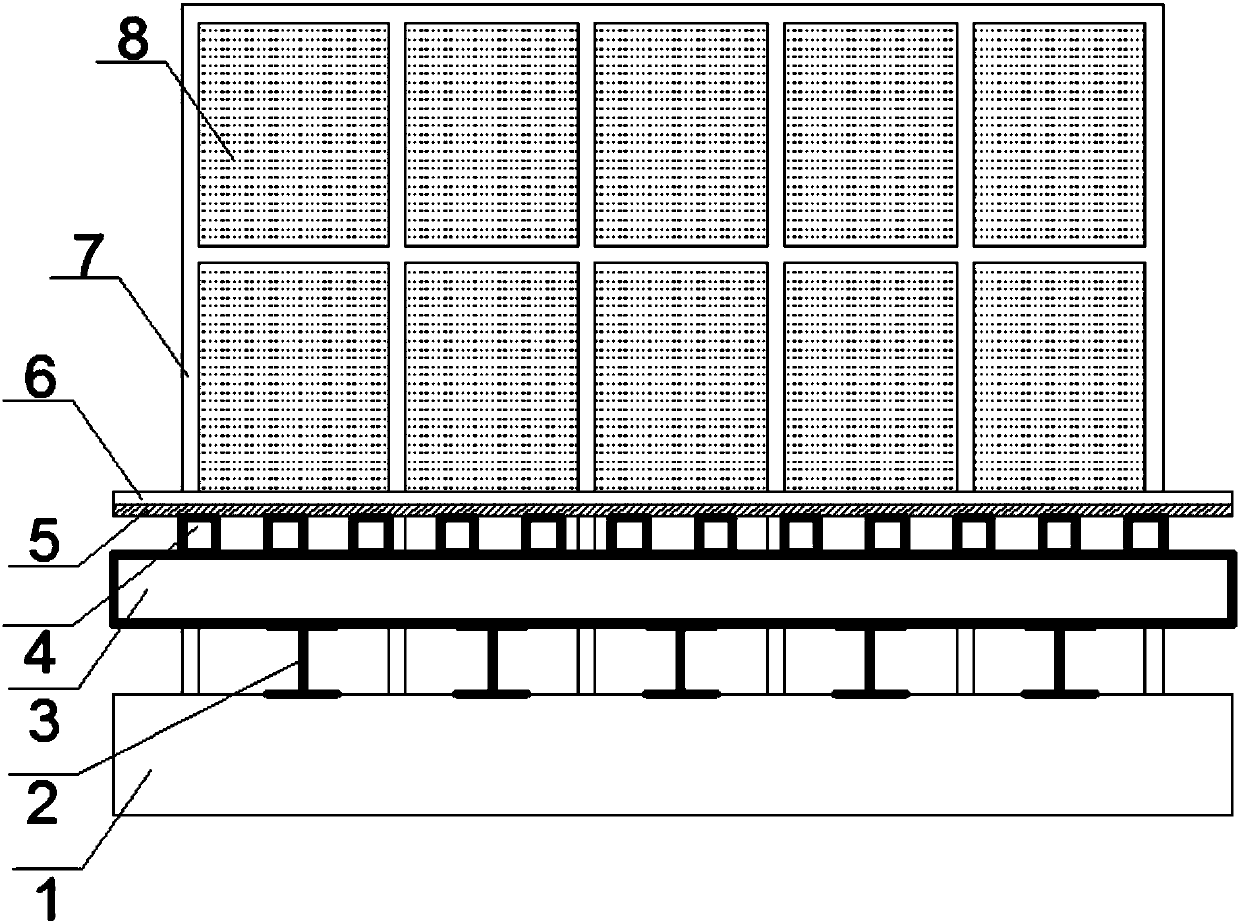

[0028] refer to figure 1 , a steel platform, used for foundation pit engineering construction operations, including the main beam I-steel layer 2, the secondary beam I-steel layer 3, the wooden frame 4, the wooden The formwork 5 and patterned steel plate 6, the I-steel layer 3 of the main beam and the I-steel layer 3 of the secondary beam are connected by welding, and the wooden frame 4 and the wooden formwork 5 are connected by steel nails.

[0029] The steel platform of this embodiment, since it is arranged above the support of the foundation pit, makes full use of the bearing capacity of the foundation pit support and the space above the foundation pit, and solves the problem of insufficient working space in the construction of the foundation pit. In addition, the steel platform of this embodiment uses the main girder I-steel layer 2 and the secondary girder I-steel layer 3 as the main force-bearing members of the steel platform, which has the advantages of convenient lifti...

Embodiment 2

[0033] refer to figure 1 , the technical scheme of the construction method of a kind of steel platform of the present embodiment is as follows, comprises the steps:

[0034] In the first step, a number of main girder I-beams are hoisted to the support beams of the foundation pit, and placed on the foundation pit support beams 1 at intervals to form the main girder I-beam layer 2;

[0035] In the second step, a number of secondary beam I-beams are hoisted to the main beam I-beam layer 2, and placed on the main beam I-beam layer 2 at intervals to form a secondary beam I-beam layer 3, and the main beam I-beam layer 2 Layer 2 and secondary beam I-beam layer 3 are connected by welding;

[0036] In the third step, several wooden squares are hoisted to the secondary beam I-steel layer 3, and placed on the secondary beam I-steel layer 3 at intervals to form a wooden square skeleton 4;

[0037] In the fourth step, the wooden formwork 5 is hoisted to the wooden frame 4, and laid on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com