A method for preparing a composite sheet comprising low-damage and aligned SIC nanowires

A technology of oriented alignment and composite materials, which is applied in the field of preparation of composite material sheets, can solve problems such as uniform dispersion, SiC nanowire breakage, and easy agglomeration of SiC nanowires, and achieve the effects of reducing damage, simple process, and solving extremely easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0037] Specific Embodiment 1: In this embodiment, a method for preparing a composite sheet comprising low-damage and oriented SiC nanowires is carried out in the following steps:

[0038] 1. Weighing:

[0039] Weigh 1-15 parts of SiC nanowires, 20-50 parts of solvent, 0.01-0.5 parts of dispersant, 5-20 parts of plasticizer and 14.5-69.99 parts of binder as raw materials in parts by mass ;

[0040] 2. Pre-dispersion of SiC nanowires:

[0041] Put the SiC nanowires, solvent and dispersant weighed in step 1 into a ball mill container, and ultrasonically treat them for 1 to 30 minutes at an ultrasonic power of 200 to 400 W to obtain a pre-dispersed slurry of SiC nanowires; the volume of the ball mill container is 3 to 20 times the solvent volume;

[0042] 3. SiC nanowire low damage ball mill dispersion:

[0043] Add the plasticizer and binder weighed in step 1 into the ball mill container containing the SiC nanowire pre-dispersed slurry obtained in step 2, and then add ball mi...

specific Embodiment approach 2

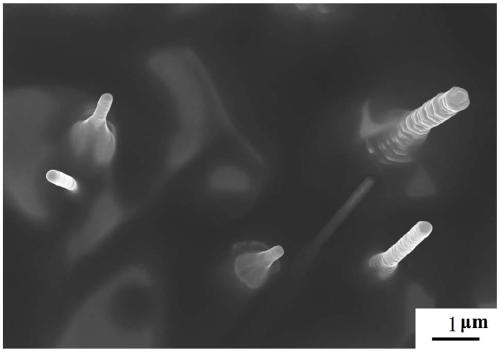

[0054] Specific embodiment 2: This embodiment differs from specific embodiment 1 in that: the SiC nanowires described in step 1 are any combination of one or more of 3C, 2H, 4H, and 6H; the average diameter of the SiC nanowires 5-250 nm, and the length of SiC nanowires is 20-100 μm. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0055] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the solvent in Step 1 is a mixture of absolute ethanol and n-butanol in a mass ratio (0.5-1):1. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com