Case bag logo mounting operating table

An operating table and sign technology, applied in the field of luggage logo sign installation operating table, can solve the problems of low efficiency of manual installation and installation, expensive installation equipment, increase the burden of enterprise feed, etc., and achieve good use effect, low cost, and improved The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

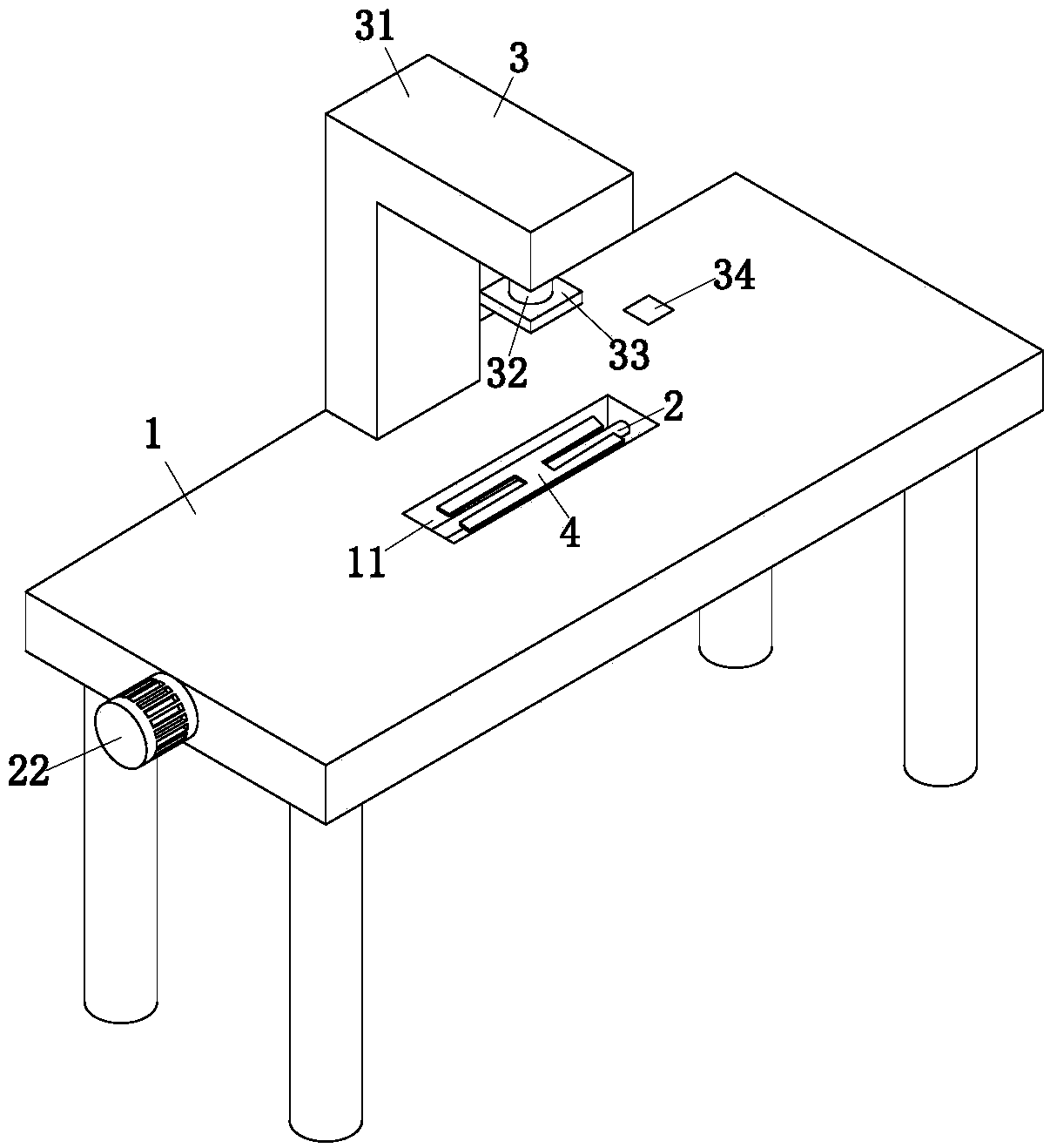

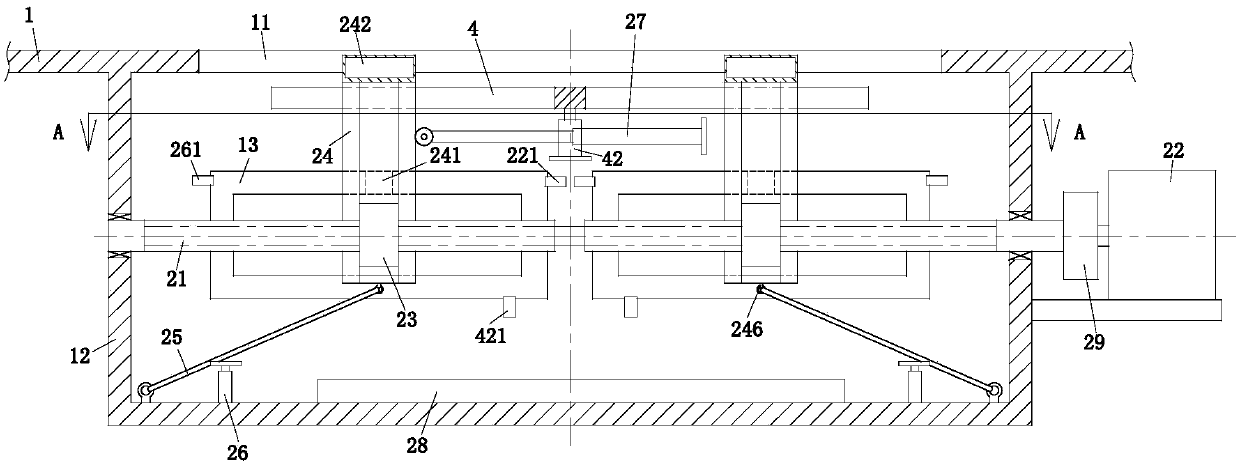

[0019] As an embodiment of the present invention, the pressing unit 3 includes an L-shaped bracket 31, a pressing telescopic rod 32, a pressing plate 33 and a trigger 34, and the pressing telescopic rod 32 is installed upside down on the Directly above the groove 11 , the lower pressing plate 33 is detachably mounted on the lower end of the lower telescopic rod 32 , and the trigger 34 is used to control the up and down movement of the lower telescopic rod 32 . Further, the downward-pressing telescopic rod 32 is a telescopic cylinder, which is connected to the air chamber 28, and the trigger 34 is a reversing valve, which can control the extension and retraction of the telescopic cylinder.

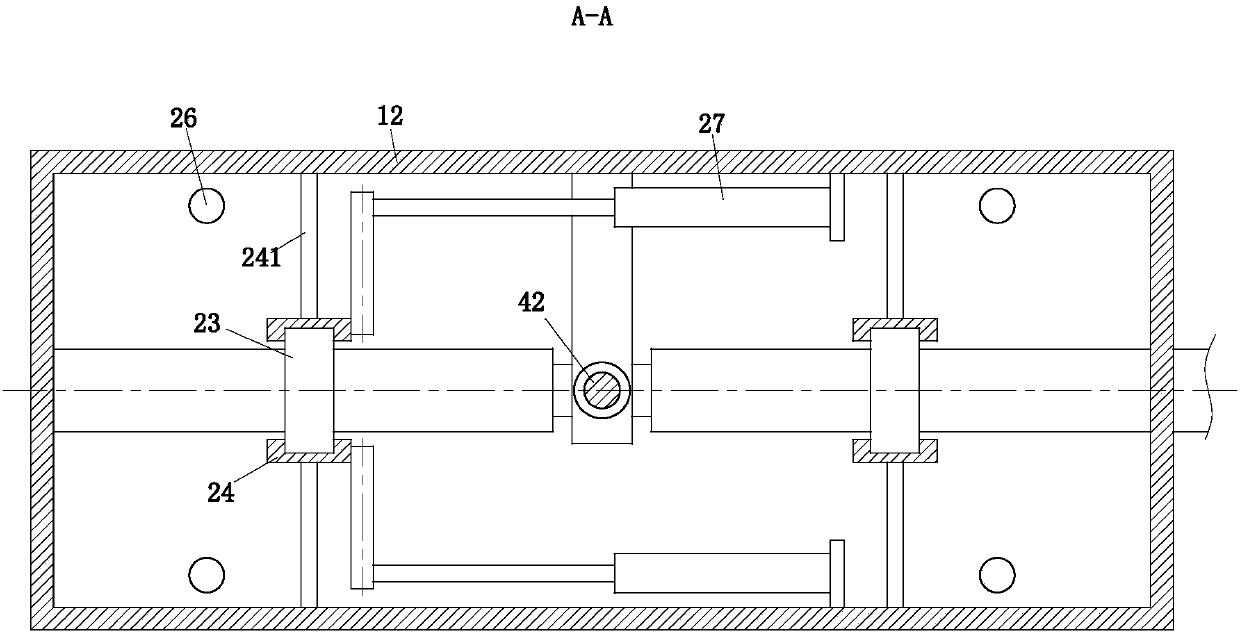

[0020] As an embodiment of the present invention, the groove 11 is provided with a pressing plate 4, and the left and right ends of the pressing plate 4 are provided with open slots 41, and the bending slider 24 can slide in the open slots 41, and The width of bending slider 24 is equal to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com