Tea leaf processing method

A processing method and tea technology, which are applied in the field of tea processing and production, can solve the problems of difficult discharge of water vapor, high water content of tea leaves, and poor air circulation, and achieve the effects of reducing the floor space, uniform heating, and saving the cost of use space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below by means of specific embodiments:

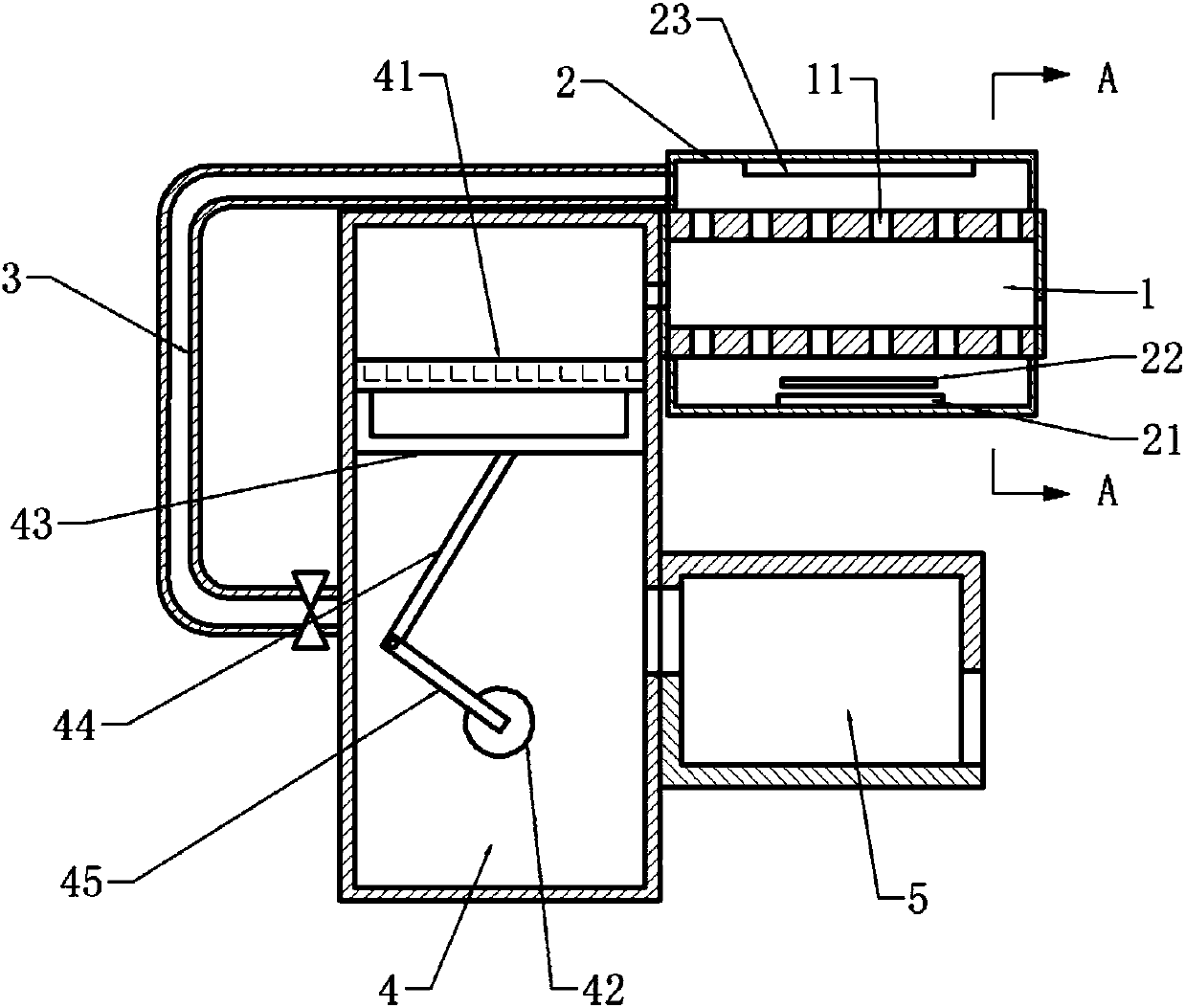

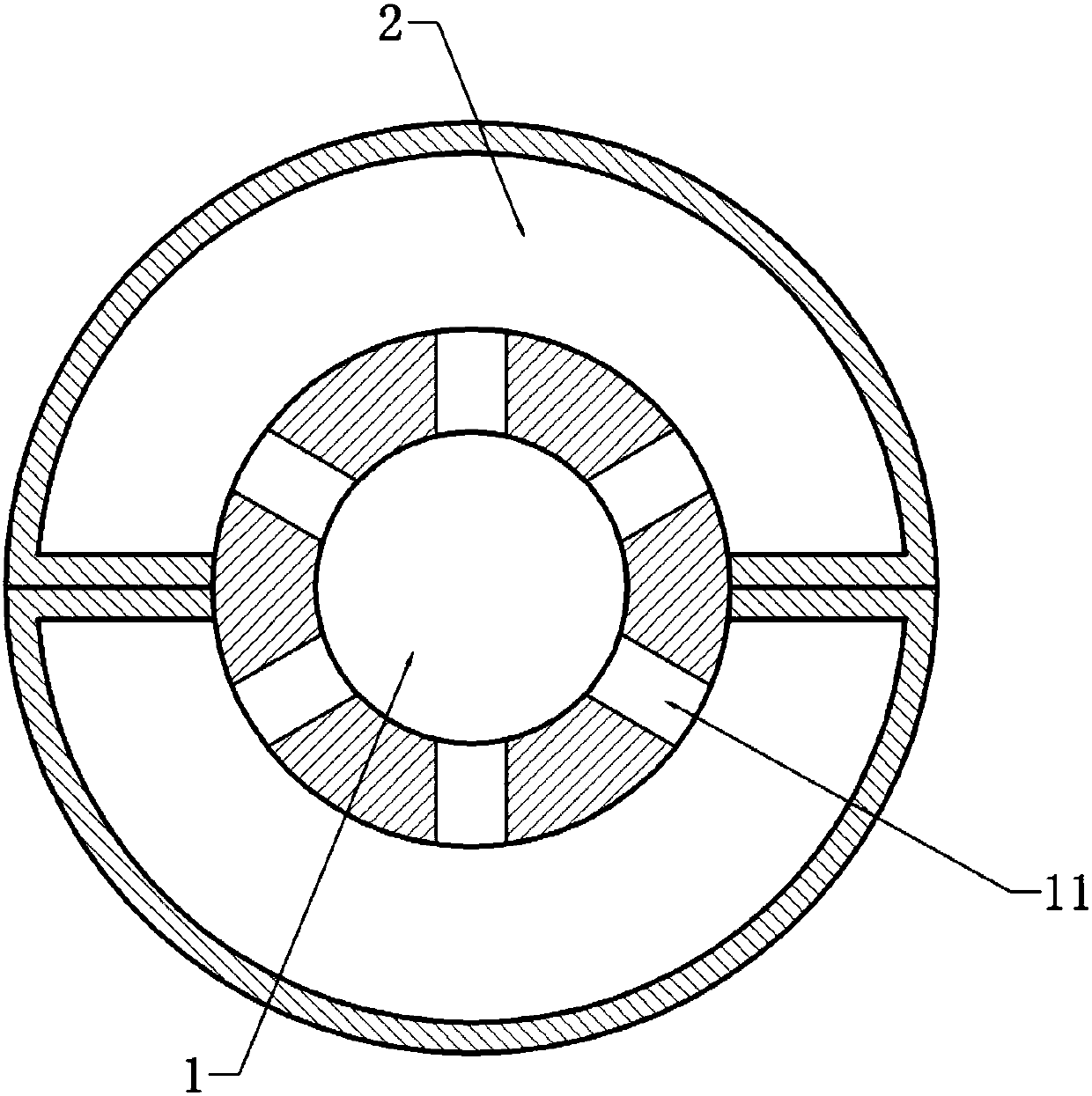

[0036] The reference signs in the accompanying drawings of the specification include:

[0037] Drying bucket 1, through hole 11, shell 2, blower 21, heating pipe 22, water absorption layer 23, air guide pipe 3, screening cylinder 4, screening disc 41, turntable 42, push block 43, connecting rod 44, rotating rod 45 , receiving box 5. Such as figure 1 As shown, a tea drying device includes a frame, on which a drying barrel 1 is rotatably connected, and the left and right ends of the drying barrel 1 are provided with end covers, and the bottom of the right end cover is provided with an inlet, and the left The lower part of the side end cover is provided with an outlet, and the outlet is higher than the inlet. The right side of the frame is provided with a motor, and the output shaft of the motor is fixedly connected with the right end cover; the right side of the frame is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com