Through hole manufacturing method

A manufacturing method and process technology, applied in the field of semiconductor integrated circuit manufacturing, can solve the problems of different types and proportions of crystal structures of barrier layers, affecting the chemical and physical properties of thin films, and affecting the formation of metal tungsten films, etc., to achieve stable properties and prevent residues. , lattice complete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

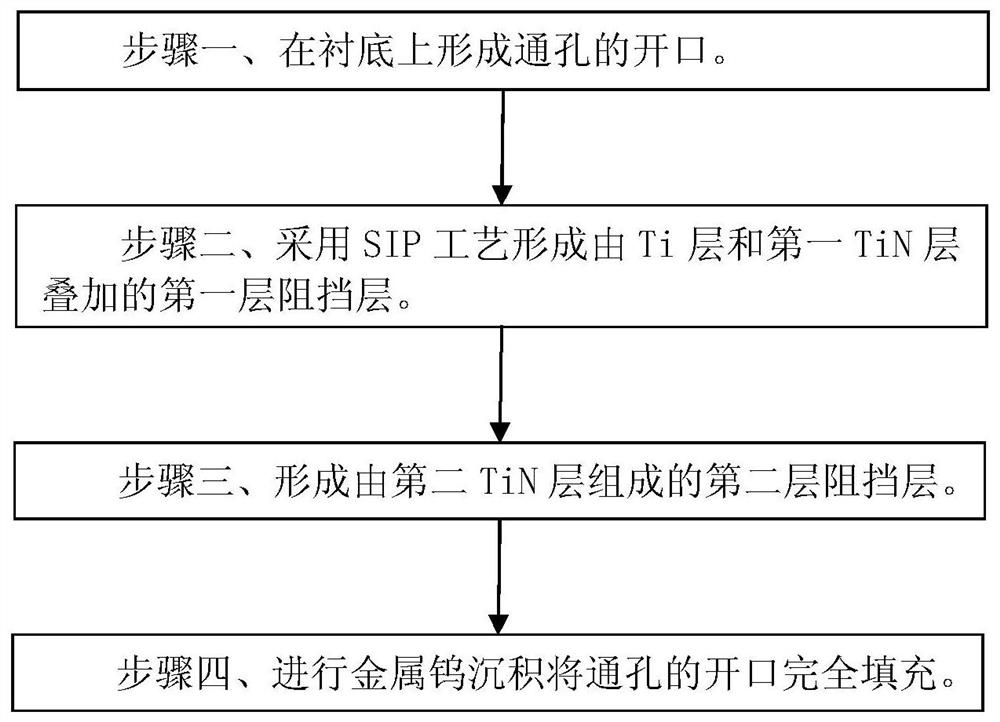

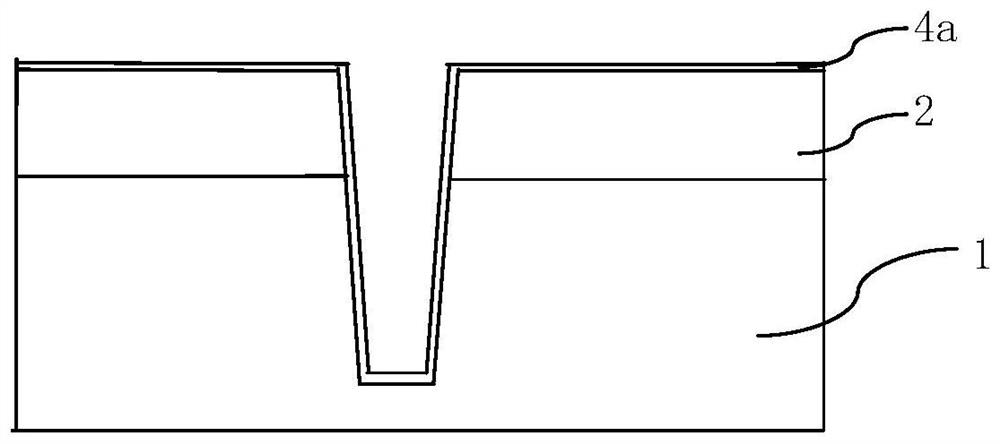

[0026] like figure 1 Shown is the flowchart of the manufacturing method of the through hole of the embodiment of the present invention, as Figure 2A to Figure 2C As shown, it is a schematic diagram of the device structure in each step of the method of the embodiment of the present invention. The method for manufacturing the through hole of the embodiment of the present invention includes the following steps:

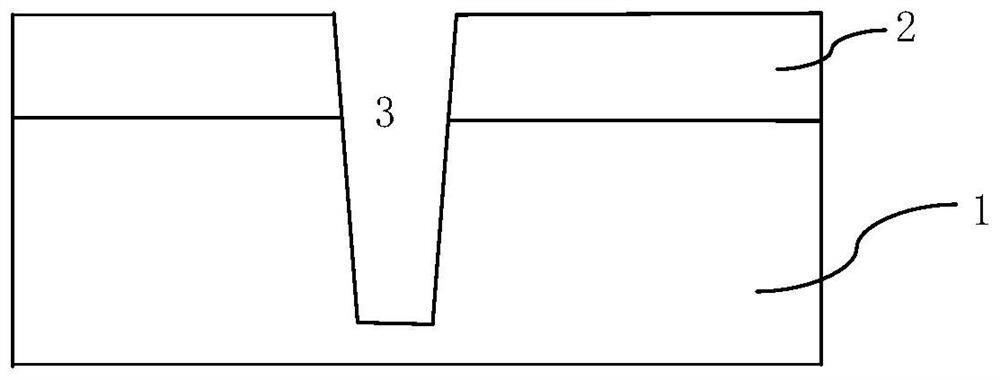

[0027] Step 1, such as Figure 2A As shown, an opening 3 of a through hole is formed on a substrate 1 .

[0028] In the embodiment of the present invention, a bottom metal layer is formed on the substrate 1 in step 1, and an interlayer film 2 is formed on the bottom metal layer; the opening 3 of the through hole passes through the interlayer film 2. Figure 2A 2 only simply shows the structure of the interlayer film 2, the substrate 1 and the opening 3, and does not show the bottom metal layer. In practical applications, the bottom metal layer is located at the bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com