Clamp for testing core glue and steel wire rope bonding intensity

A technology of bonding strength and steel wire rope, which is applied in the field of jigs for testing the bonding strength of core rubber and steel wire rope, and can solve the problems of poor fixing reliability, low fixing efficiency, time-consuming and laborious operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

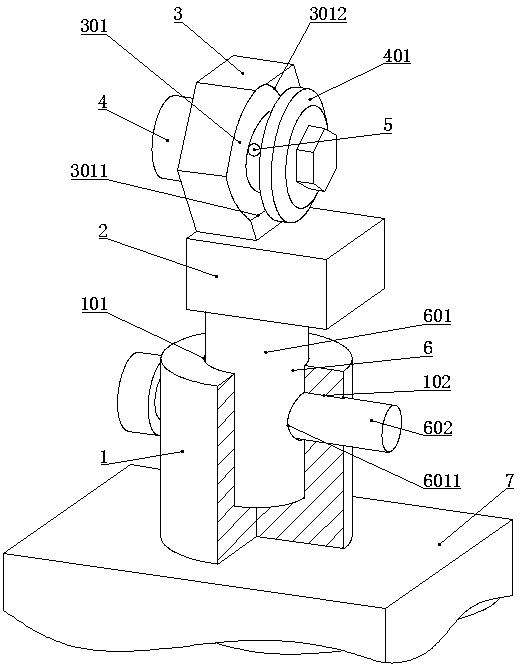

[0015] exist figure 1 Among them, a fixture for testing the adhesive strength of core rubber and steel wire rope, including a connecting seat 1, a fixing table 2, a nut 3 and a bolt 4.

[0016] Such as figure 1 As shown, the connection base 1 is fixedly assembled on the traction device 7 . The fixed platform 2 is detachably assembled on the connecting base 1 via the connecting piece 6 . The nut 3 is welded on the fixing table 2, and the screw hole of the nut 3 is arranged in the horizontal direction. The bolt 4 is screwed on the nut 3 , and the shaft portion of the bolt 4 is radially provided with a piercing hole 5 .

[0017] It should be further explained that the connecting piece 6 can be a conventional connecting piece. exist figure 1 In this embodiment, the connecting member 6 includes a fixing pin 602 and a connecting shaft 601 . Such as figure 1 As shown, the connecting shaft 601 is fixedly connected to the bottom of the fixed table 2, and a shaft hole 101 is open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com