Antibacterial kapok blend fiber, antibacterial filling flocculus, antibacterial kapok yarn and fabric

A technology of mixing fibers and kapok fibers, applied in the field of textiles, can solve the problems of difficult textile processing and low degree of industrialization of kapok, and achieve the effects of improving strength, compression recovery performance, and good antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

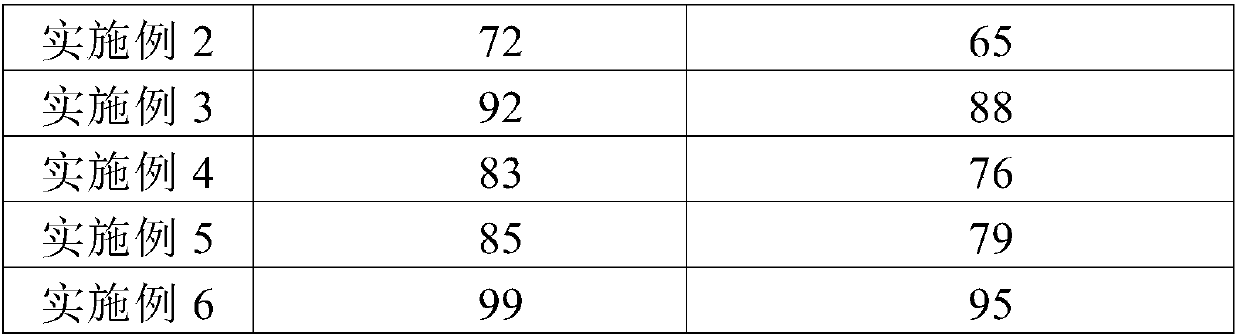

Examples

Embodiment 1

[0054] A preparation method for antibacterial filled flakes, comprising the following steps:

[0055] S1 Opening and mixing: Mix the antibacterial kapok mixed fiber, conventional humidification, and then open it with a WL-GK-D-500 opener (Taicang Shuangfeng Nonwoven Equipment Co., Ltd.), and remove the sundries at the same time;

[0056] S2 carding: use WL-GP-B-800 carding machine (Taicang Shuangfeng Nonwoven Equipment Co., Ltd.) to card the antibacterial kapok mixed fibers after opening and impurity removal treatment, and obtain fibers in a single fiber state;

[0057] S3 web laying: The fibers in the single fiber state are stripped with a chopping knife to form a single-layer fiber web, and the multi-layer fiber web is formed by a WL-GZ-A-800 web-laying machine (Taicang Shuangfeng Nonwovens Equipment Co., Ltd.) The single webs are stacked together to form a multi-layer fiber web, and the unit weight of the multi-layer fiber web is controlled to be 450g / m 2 ;

[0058] S4 Ac...

Embodiment 2

[0063] A preparation method for antibacterial filled flakes, comprising the following steps:

[0064] S1 Opening and mixing: Mix the antibacterial kapok mixed fiber, conventional humidification, and then open it with a WL-GK-D-500 opener (Taicang Shuangfeng Nonwoven Equipment Co., Ltd.), and remove the sundries at the same time;

[0065] S2 carding: use WL-GP-B-800 carding machine (Taicang Shuangfeng Nonwoven Equipment Co., Ltd.) to card the antibacterial kapok mixed fibers after opening and impurity removal treatment, and obtain fibers in a single fiber state;

[0066] S3 web laying: The fibers in the single fiber state are stripped with a chopping knife to form a single-layer fiber web, and the multi-layer fiber web is formed by a WL-GZ-A-800 web-laying machine (Taicang Shuangfeng Nonwovens Equipment Co., Ltd.) The single webs are stacked together to form a multi-layer fiber web, and the unit weight of the multi-layer fiber web is controlled to be 450g / m 2 ;

[0067] S4 Ac...

Embodiment 3

[0077] A preparation method for antibacterial filled flakes, comprising the following steps:

[0078] S1 Opening and mixing: Mix the antibacterial kapok mixed fiber, conventional humidification, and then open it with a WL-GK-D-500 opener (Taicang Shuangfeng Nonwoven Equipment Co., Ltd.), and remove the sundries at the same time;

[0079] S2 carding: use WL-GP-B-800 carding machine (Taicang Shuangfeng Nonwoven Equipment Co., Ltd.) to card the antibacterial kapok mixed fibers after opening and impurity removal treatment, and obtain fibers in a single fiber state;

[0080] S3 web laying: The fibers in the single fiber state are stripped with a chopping knife to form a single-layer fiber web, and the multi-layer fiber web is formed by a WL-GZ-A-800 web-laying machine (Taicang Shuangfeng Nonwovens Equipment Co., Ltd.) The single webs are stacked together to form a multi-layer fiber web, and the unit weight of the multi-layer fiber web is controlled to be 450g / m 2 ;

[0081] S4 Ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com