Preparation method of paint remover

A paint remover and solvent oil technology, applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems of undisclosed paint stripping, improve storage stability, improve stability, slow down volatilization and slope loss rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

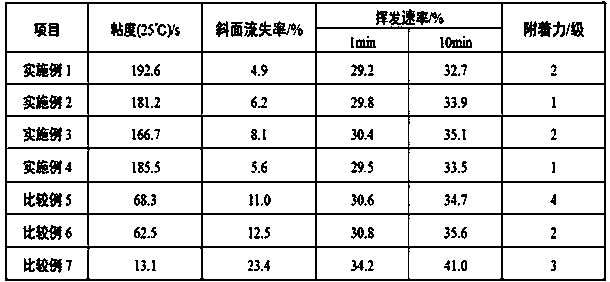

Examples

Embodiment 1

[0043] A kind of preparation method of paint remover, comprises the following steps by weight proportioning:

[0044] S1. Pretreatment of paraffin wax, mix 8 parts of DBE mixed dibasic acid ester, 4.997 parts of propylene glycol methyl ether and 2.2 parts of fully refined paraffin wax, heat at 86-110°C, dissolve until visually transparent and free of lumps, and then the paraffin wax is melted mixture;

[0045] S2. Add 1.8 parts of 200# solvent oil, 1 part of 120# solvent oil, and 25 parts of dimethyl carbonate into the reaction tank, and heat to 36-42°C while stirring;

[0046] S3. Under the state of stirring and heat preservation at 36-42°C, add the paraffin wax mixture, and disperse for 12-20 minutes until the mixture is uniform;

[0047] S4. Add 10 parts of methanol and 33 parts of dichloromethane, keep warm at 35-42°C and disperse evenly, then add 8 parts of formic acid microcapsules and 2.5 parts of oleic acid triethanolamine emulsifier and continue to disperse for 5-10 ...

Embodiment 2

[0055] A kind of preparation method of paint remover, comprises the following steps by weight proportioning:

[0056] S1. Pretreatment of paraffin wax, mix 10 parts of DBE mixed dibasic acid ester, 3.998 parts of propylene glycol methyl ether and 1.2 parts of OP wax, heat at 86-110°C, dissolve until visually transparent and free of lumps, and obtain a paraffin wax melt mixture ;

[0057] S2. Add 2.5 parts of 200# solvent oil, 1 part of 120# solvent oil, and 21 parts of dimethyl carbonate into the reaction tank, and heat to 36-42°C while stirring;

[0058] S3. Under the state of stirring and heat preservation at 36-42°C, add the paraffin wax mixture, and disperse for 12-20 minutes until the mixture is uniform;

[0059] S4. Add 7 parts of methanol and 42 parts of dichloromethane, keep warm at 35-42°C and disperse evenly, then add 5 parts of formic acid microcapsules and 3.5 parts of oleic acid triethanolamine emulsifier and continue to disperse for 5-10 minutes;

[0060] S5. A...

Embodiment 3

[0065] A kind of preparation method of paint remover, comprises the following steps by weight proportioning:

[0066] S1. Pretreatment of paraffin wax, mix 12 parts of DBE mixed dibasic acid ester, 2.996 parts of propylene glycol methyl ether, 0.7 part of fully refined paraffin wax, and 1.2 parts of OP wax, heat at 86-110 ° C, and dissolve until visually transparent and free of lumps , to obtain the paraffin wax melt mixture;

[0067] S2. Add 1 part of 200# solvent oil, 0.5 part of 120# solvent oil, and 18 parts of dimethyl carbonate into the reaction tank, and heat to 36-42°C while stirring;

[0068] S3. Under the state of stirring and heat preservation at 36-42°C, add the paraffin wax mixture, and disperse for 12-20 minutes until the mixture is uniform;

[0069] S4. Add 8 parts of methanol and 48 parts of dichloromethane, keep warm at 35-42°C and disperse evenly, then add 3 parts of formic acid microcapsules and 3 parts of oleic acid triethanolamine emulsifier and continue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com