Non-migratory poss grafted antioxidant and preparation method thereof

A non-migration, anti-aging agent technology, applied in the field of rubber anti-aging agents, can solve the problems of unfavorable anti-aging agents uniform dispersion, reduction of anti-aging agent protection efficiency, and affecting the uniform dispersion of anti-aging agents, so as to increase compatibility and anti-atomic oxygen performance, Excellent resistance to thermo-oxidative aging and the effect of prolonging the oxidation induction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 9 mass parts of heptaphenyl epoxy POSS and 5 mass parts of RT base are dissolved in 100 mass parts of anhydrous toluene to form a reaction system, nitrogen is used to remove the air in the system, and heating is started under nitrogen protection. After the system started to reflux, add 0.01 parts by mass of platinum catalyst through a micro-syringe, and heat to 120°C and stir the reaction for at least 36 hours. After the reaction, the solvent was removed to obtain a solid product, and the obtained solid product was subjected to Soxhlet extraction with methanol as a solvent to remove no The RT base that participates in the grafting reaction, the solid product obtained after the extraction is vacuum-dried to obtain the non-migrating POSS grafted anti-aging agent (RTPO). The structural formula of heptaphenyl epoxy POSS is:

[0032]

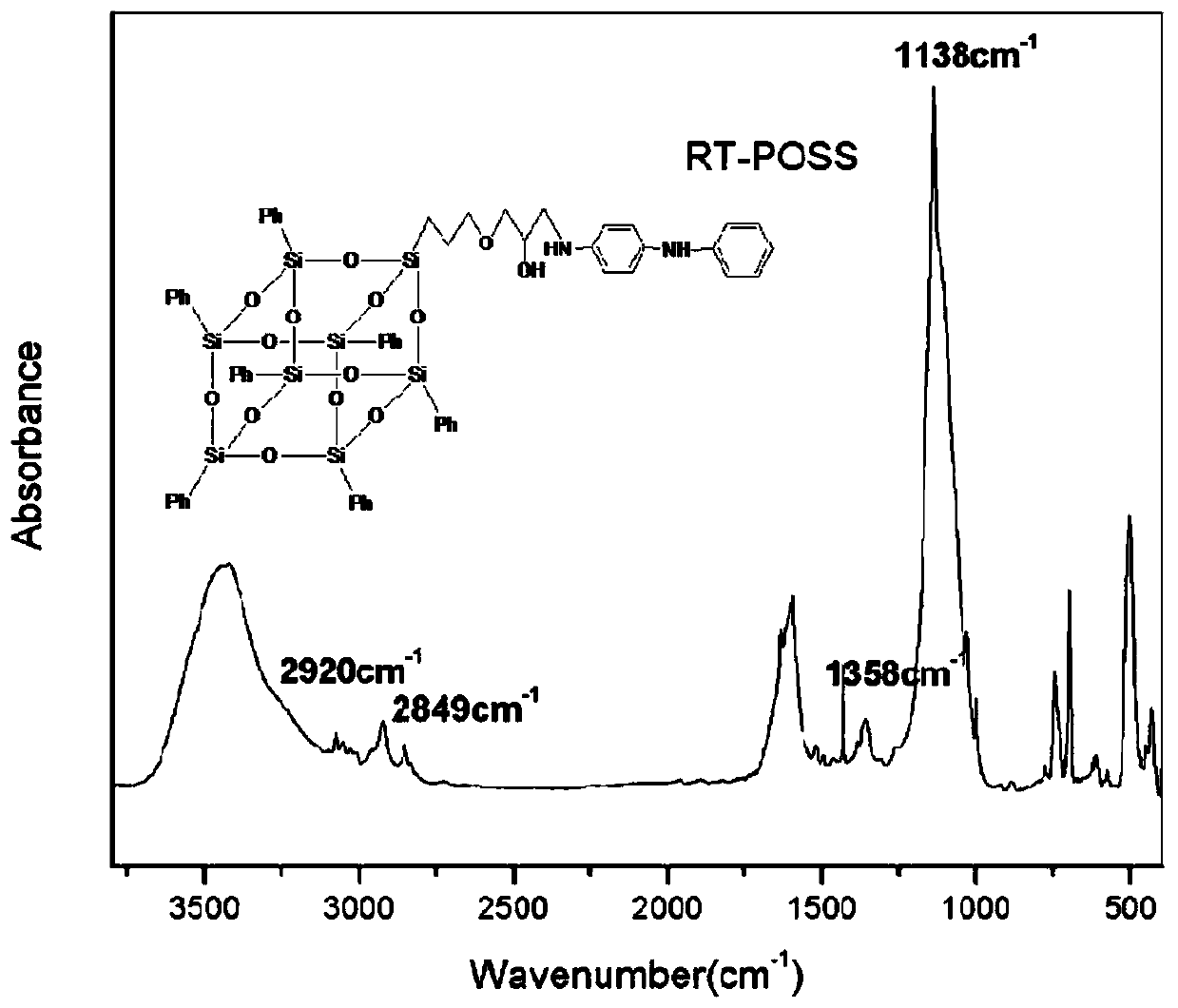

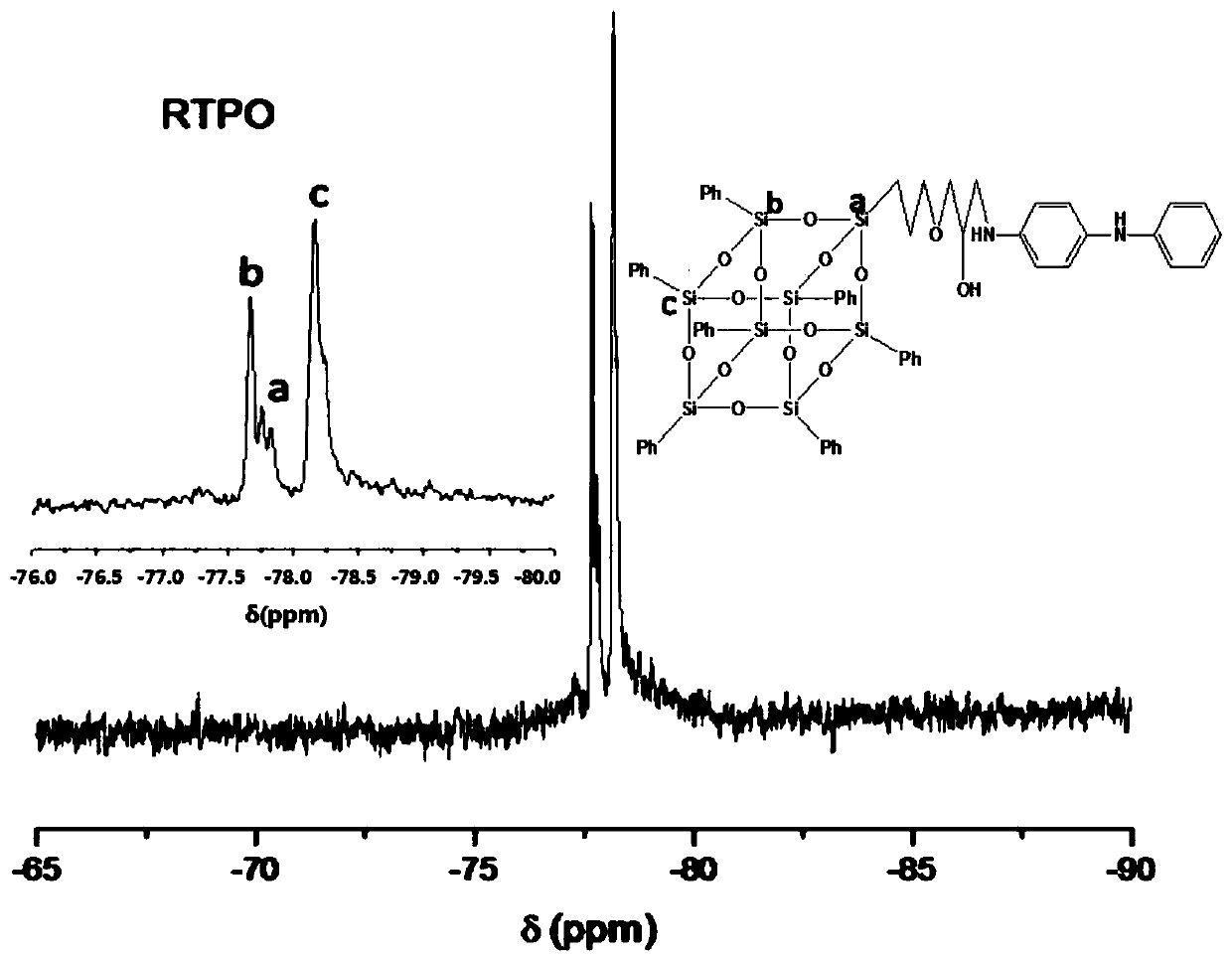

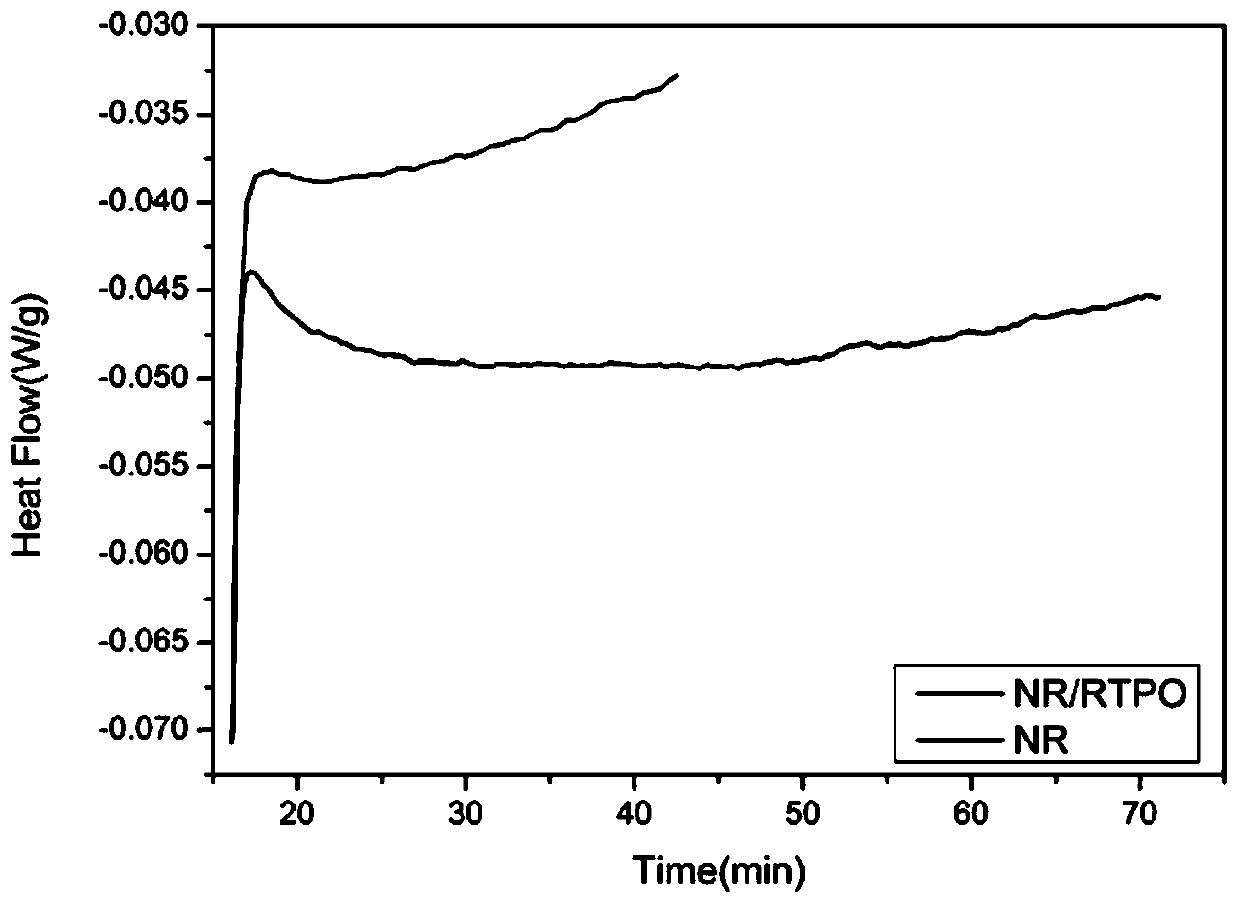

[0033] Infrared characterization of RTPO, the results are shown in figure 1 , at 2957cm -1 and 2934cm -1 The absorption peak appearing ...

Embodiment 2

[0036]The heptamethyl epoxy POSS of 14 mass parts and the RT base of 10 mass parts are jointly dissolved in the anhydrous toluene of 100 mass parts to form reaction system, adopt nitrogen to get rid of the air in the system, then start heating under nitrogen protection, After the system starts to reflux, add 0.03 parts by mass of nickel catalyst through a micro-syringe, and heat to 100°C and stir for 36 hours. After the reaction, the solvent anhydrous toluene is removed to obtain a solid product, and the obtained solid product is subjected to Soxhlet extraction with methanol as a solvent. , remove the RT base that does not participate in the grafting reaction, and vacuum-dry the solid product obtained after the extraction to obtain a non-migratory POSS grafted anti-aging agent (RTPO).

[0037] The structural formula of heptamethyl epoxy POSS is:

[0038]

Embodiment 3

[0040] Dissolve 20 parts by mass of heptabutyl epoxy POSS and 15 parts by mass of RT base in 100 parts by mass of anhydrous toluene to form a reaction system, use nitrogen to remove the air in the system, start heating under nitrogen protection, and wait for the system to start After reflux, add 0.03 parts by mass of nickel catalyst through a micro syringe, heat to 100°C and stir to react for at least 36 hours. After the reaction, the solvent is removed to obtain a solid product, and the obtained solid product is subjected to Soxhlet extraction with methanol as a solvent to remove the components that did not participate in the reaction. The RT base of the branch reaction, the solid product obtained after the extraction is vacuum-dried to obtain the non-migratory POSS grafted anti-aging agent (RTPO). The structural formula of heptabutyl epoxy POSS is:

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation induction time | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com