Preparation method of biologically modified composite material

A composite material and biological modification technology, applied in the field of vegetable pest control, can solve problems such as crop quality decline, ecosystem damage, harm to human health, etc., and achieve the effects of increasing porosity, increasing specific surface, and protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

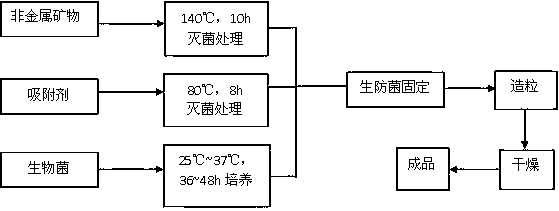

Method used

Image

Examples

Embodiment 1

[0025] (1) Selection of non-metallic minerals: mix bentonite and barite in a ratio of 7:3;

[0026] (2) Drying and crushing: the non-metallic mineral raw materials are crushed to ≤5mm, and the raw materials enter the sorting machine for dry purification, and the non-metallic mineral raw materials with a taste of ≥85% are collected;

[0027] (3) The biosorbent is a mixture of corn stalks and coal ash, the particle size after mixing is controlled at 150 mesh, and the addition amount is 20%;

[0028] (4) Bacillus is selected as the biological bacteria;

[0029] (5) Bake the non-metallic minerals in an oven at 140°C for 10 hours, and bake the adsorbent in an oven at 80°C for 8 hours for sterilization;

[0030] (6) Cultivate the biological bacteria in the growth chamber at 30°C for 40 hours;

[0031] (7) The sterilized non-metallic minerals, adsorbent and biological bacteria are mixed in a ratio of 3:1:1 for biological bacteria immobilization;

[0032] (8) After the bio-control ...

Embodiment 2

[0036] (1) Selection of non-metallic minerals: mix bentonite, barite, and vermiculite in a ratio of 5:3:2;

[0037] (2) Drying and crushing: the non-metallic mineral raw materials are crushed to ≤5mm, and the raw materials enter the sorting machine for dry purification, and the non-metallic mineral raw materials with a taste of ≥85% are collected;

[0038] (3) The biosorbent is a mixture of corn stalks and coal ash, the particle size after mixing is controlled at 200 mesh, and the addition amount is 30%;

[0039] (4) Bacillus and Lactic acid streptococcus are selected as biological bacteria;

[0040] (5) Bake the non-metallic minerals in an oven at 140°C for 9 hours, and bake the adsorbent in an oven at 80°C for 6 hours for sterilization;

[0041] (6) The biological bacteria were cultured in the growth room at 30°C for 45 hours;

[0042] (7) The sterilized non-metallic minerals, adsorbent and biological bacteria are mixed in a ratio of 3:1:1 for biological bacteria immobiliz...

Embodiment 3

[0047] (1) Selection of non-metallic minerals: mix bentonite, barite, vermiculite and medical stone according to the ratio of 4:2:2:2;

[0048] (2) Drying and crushing: the non-metallic mineral raw materials are crushed to ≤5mm, and the raw materials enter the sorting machine for dry purification, and the non-metallic mineral raw materials with a taste of ≥85% are collected;

[0049] (3) The biosorbent is a mixture of corn stalks and coal ash, the particle size after mixing is controlled at 300 mesh, and the addition amount is 25%;

[0050] (4) Bacillus, Lactococcus and Lactococcus are selected as biological bacteria;

[0051] (5) Bake the non-metallic minerals in an oven at 140°C for 8 hours, and bake the adsorbent in an oven at 80°C for 7 hours for sterilization;

[0052] (6) The biological bacteria were cultured in the growth room at 30°C for 48 hours;

[0053] (7) The sterilized non-metallic minerals, adsorbent and biological bacteria are mixed in a ratio of 3:1:1 for biol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com