Preparation method of ZnO-CuO-FeOOH composite film for photoelectric catalysis hydrogen production

A technology of photoelectric catalysis and composite thin films, which is applied in the fields of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., which can solve the problem of few reports on photoelectrocatalytic hydrogen production and few researches on modification and other problems, to achieve the effect of simple and easy operation, low cost and good performance of the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

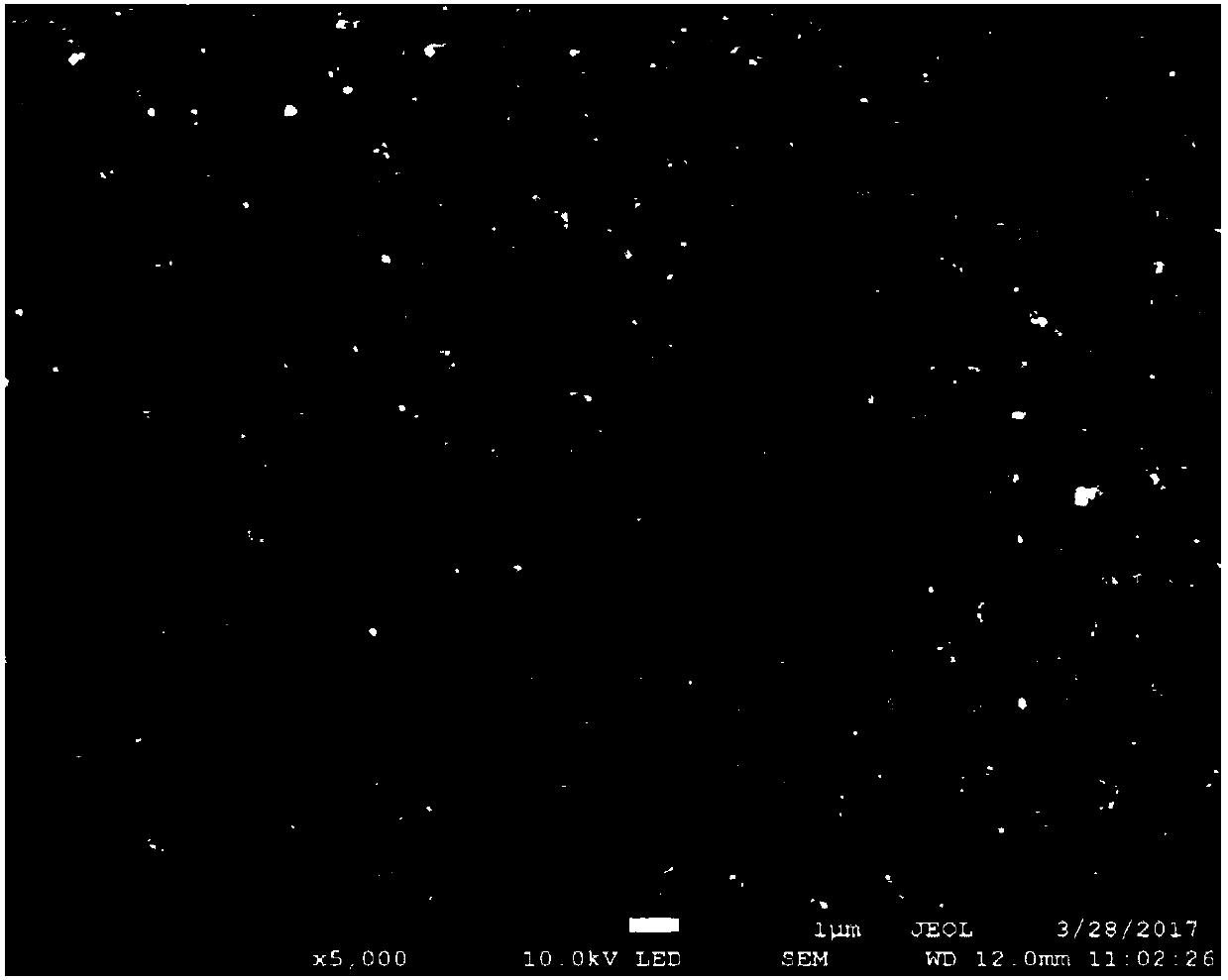

Image

Examples

Embodiment 1

[0035] Step 1: Preparation of ZnO thin film

[0036] 11g of zinc acetate [Zn(CH 3 COO) 2 2H 2 O] was added to 100ml of ethylene glycol methyl ether [CH 3 OCH 2 CH 2 OH], stirred magnetically at 45°C for 30min, then added dropwise 6ml of monoethanolamine [HO(CH 2 ) 2 NH 2 ], continue stirring for 1.5h to obtain a light yellow transparent solution, which is 0.5mol L -1 ZnO sol, the ZnO sol was left standing for 7 days to obtain light yellow transparent ZnO gel;

[0037] The ZnO seed layer was prepared by the dipping and pulling method, that is, the ZnO seed layer was plated on the conductive glass at a speed of 2mm / s, dried at 60°C, and dried at 60°C for 2h after two layers were plated in the same way; The ZnO seed layer is heated at 2°C / min to 200°C for 30 minutes, and then continues to heat up to 450°C for 1 hour to obtain the ZnO seed layer;

[0038] The hydrothermal method was used in the growth solution (the growth solution was 0.04mol L -1 zinc nitrate and hexam...

Embodiment 2

[0046] Step 1: Preparation of ZnO thin film

[0047] 3.3g of zinc acetate [Zn(CH 3 COO) 2 2H 2 O] added to 50ml of ethylene glycol methyl ether [CH 3 OCH 2 CH 2 OH], stirred magnetically at 50°C for 20min, then added dropwise 2ml of monoethanolamine [HO(CH 2 ) 2 NH 2 ], after continuing to stir for 2h, a light yellow transparent solution was obtained, which was 0.3mol L -1 ZnO sol, the ZnO sol was left standing for 7 days to obtain light yellow transparent ZnO gel;

[0048] The ZnO seed layer was prepared by the dipping and pulling method, that is, the ZnO seed layer was plated on the conductive glass at a speed of 1mm / s, dried at 80°C, and dried at 80°C for 1h after two layers were plated in the same way; The ZnO seed layer was heated at 2°C / min to 200°C for 30 minutes, and then continued to heat up to 450°C for 1 hour to obtain the ZnO seed layer;

[0049] The hydrothermal method was used in the growth solution (the growth solution was 0.05mol L -1 zinc nitrate and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com