ZIF-8/PVDF (Polyvinylidene Fluoride) ultra-filtration membrane with catalysis effect at room temperature and preparation method thereof

A ZIF-8, ultrafiltration membrane technology, used in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, ultrafiltration, etc. Complex preparation process and other problems, to achieve the effect of good interception flux, increased compatibility, and simple membrane production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

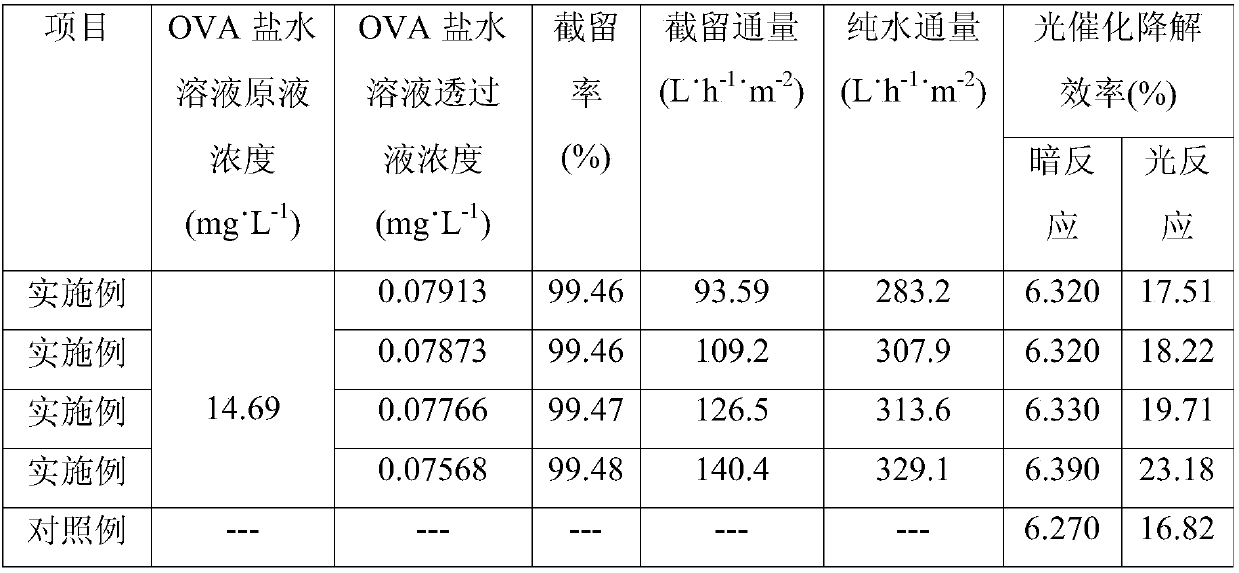

Examples

Embodiment 1

[0031] (1) With PVP as an additive, PVDF and HMIm were added to DMF for uniform blending, and the component mass ratio HMIm:PVP:PVDF=8.0:1.0:15.0 to obtain a casting solution of HMIm.

[0032] (2) After stirring the casting solution obtained in step (1) for 6 hours, let it stand for defoaming for 12 hours.

[0033] (3) Prepare 20mol / L of Zn(NO 3 ) 2 ·6H 2 O, 25vol% isopropanol in water.

[0034] (4) Scrape the casting solution in step (2) on a clean glass plate, and quickly immerse it in the gel bath of step (3) for 3 hours.

[0035] (5) Transfer the membrane prepared in (4) to circulating water for immersion to remove the solvent, and store it in deionized water for later use.

Embodiment 2

[0037] (1) With PVP as an additive, PVDF and HMIm were added to DMF for uniform blending, and the component mass ratio HMIm:PVP:PVDF=8.0:1.0:18.0 to obtain a casting solution containing HMIm.

[0038] (2) After stirring the casting solution obtained in step (1) for 10 hours, let it stand for defoaming for 8 hours.

[0039] (3) Prepare 30mol / L of Zn(NO 3 ) 2 ·6H 2 O, 60vol% isopropanol in water.

[0040] (4) Scrape the casting solution in step (2) on a clean glass plate, and quickly immerse it in the gel bath of step (3) for 6 hours.

[0041] (5) Transfer the membrane prepared in (4) to circulating water for immersion to remove the solvent, and store it in deionized water for later use.

Embodiment 3

[0043] (1) Using PVP as an additive, PVDF and HMIm were added to DMF for uniform blending, and the component mass ratio HMIm:PVP:PVDF=12.0:1.0:18.0 to obtain a casting solution containing HMIm.

[0044] (2) After stirring the casting solution obtained in step (1) for 12 hours, let it stand for defoaming for 11 hours.

[0045](3) Prepare 50mol / L of Zn(NO 3 ) 2 ·6H 2 O, 68vol% aqueous solution of isopropanol.

[0046] (4) Scrape the casting solution in step (2) on a clean glass plate, and quickly immerse it in the gel bath of step (3) for 12 hours.

[0047] (5) Transfer the membrane prepared in (4) to circulating water for immersion to remove the solvent, and store it in deionized water for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com