Method for producing conductive mayenite-type compound

A manufacturing method and compound technology, applied in chemical instruments and methods, final product manufacturing, electrochemical generators, etc., can solve problems such as complicated operations, difficult to control reactions, and long reaction times, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

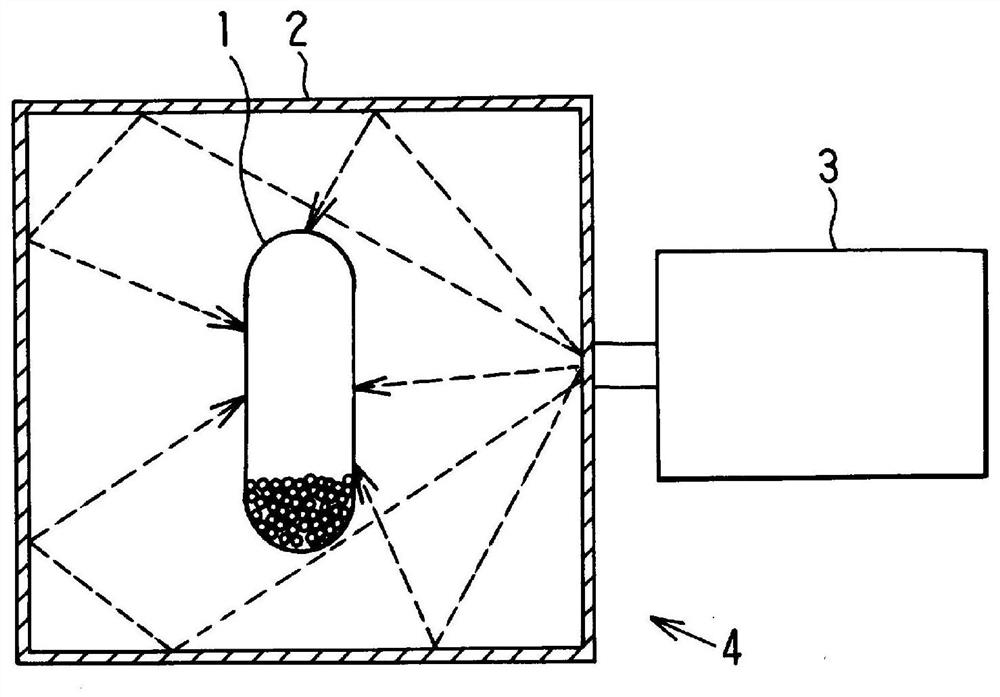

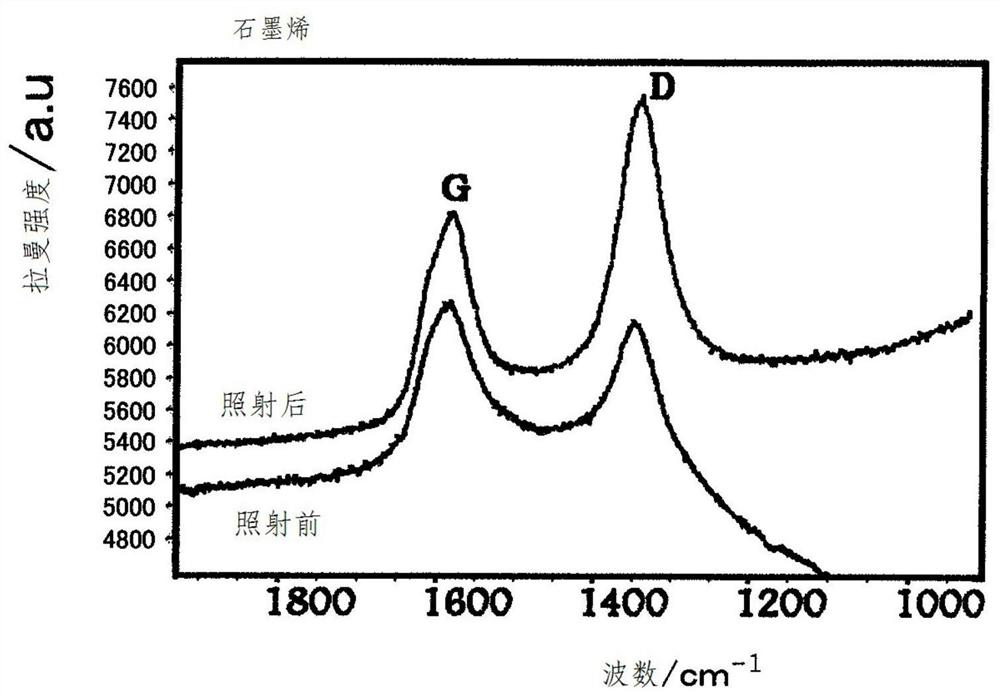

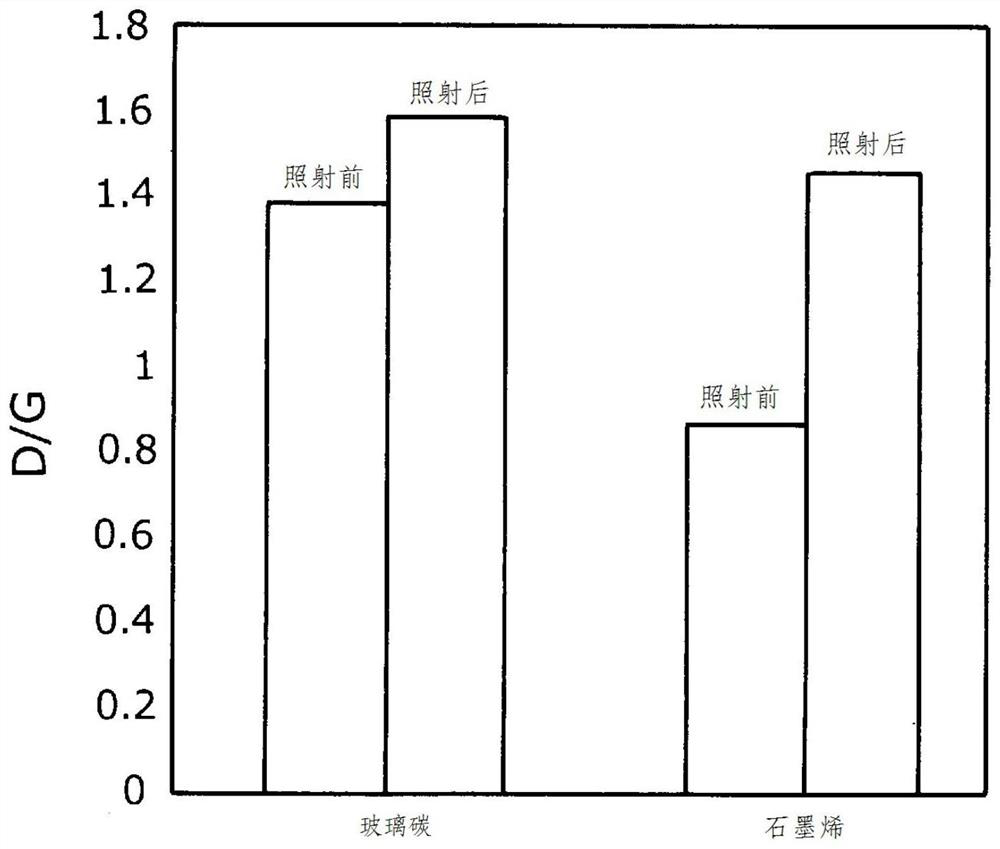

[0039]Example 1 (using glassy carbon as the carbon component and microwave irradiation under a nitrogen atmosphere) 0.22 g of mayenite-type compound was mixed with 0.035 g of glassy carbon (Aldrich Company), and the resulting mixture was contained in an ampoule tube (diameter 2.5 cm , length 15cm). Next, the inside of the ampoule tube was replaced with nitrogen so that the oxygen concentration in the tube was less than 1% (v / v), and the tube was sealed. Next, the ampoule tube is placed in the reaction vessel of the microwave generator, and the mixture in the ampoule tube is irradiated with microwaves at a frequency of 2.45 GHz for 20 minutes at a temperature of 800-900° C. by using the magnetron of the generator.

Embodiment 2

[0040] Example 2 (using glassy carbon as a carbon component and performing microwave irradiation under an argon atmosphere)

[0041] The same operation as in Example 1 was performed except that substitution with argon gas was performed instead of nitrogen gas substitution.

Embodiment 3

[0042] Example 3 (using acetylene black as a carbon component and performing microwave irradiation under a nitrogen atmosphere)

[0043] Except having used 0.029g of acetylene black (Strem Chemicals company) instead of glassy carbon, the same operation as Example 1 was performed.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap