Catalyst for purifying exhaust gases and process for producing the same

A technology for purifying exhaust gas and catalysts, which can be used in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., and can solve problems such as reducing PMs purification performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

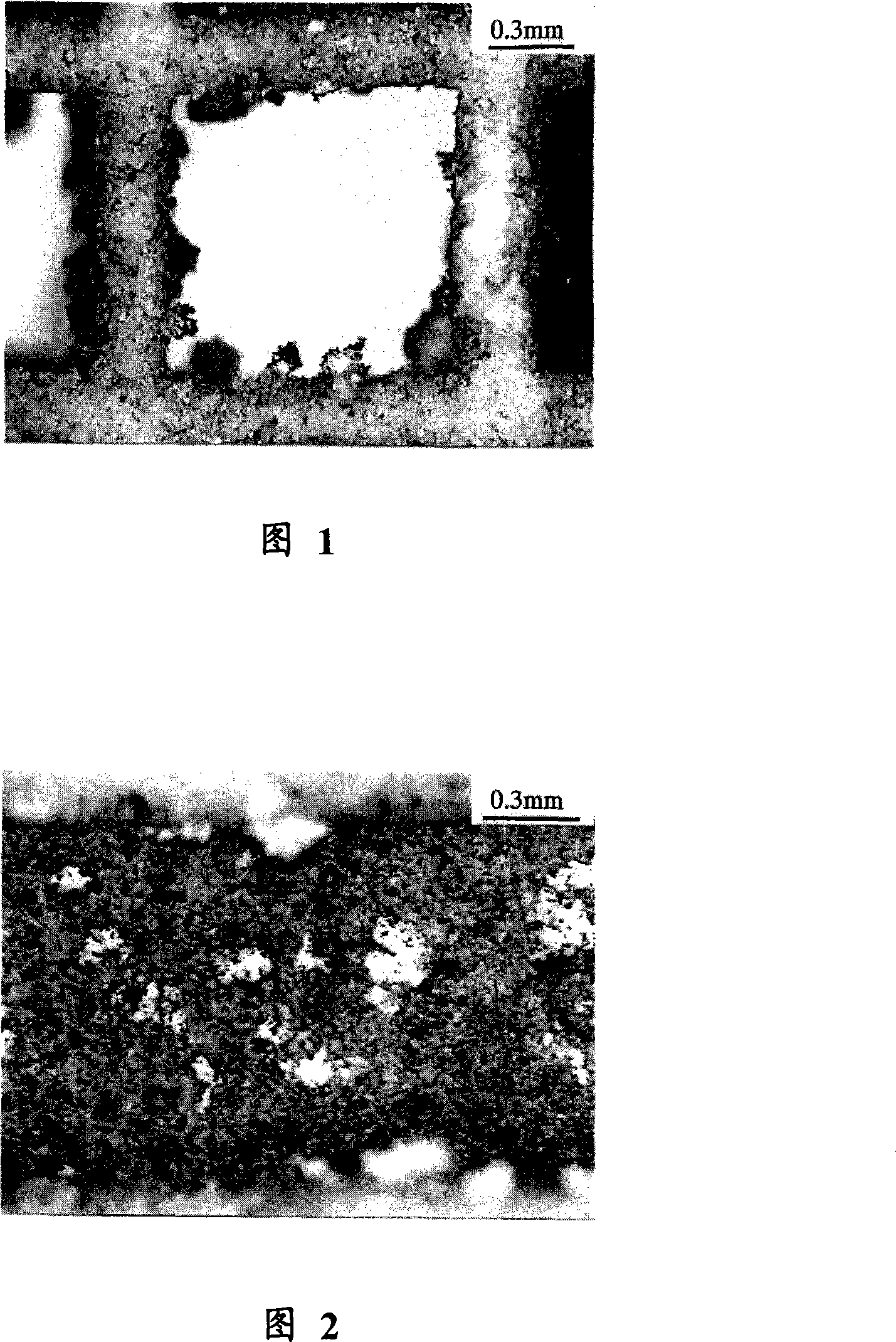

Image

Examples

Embodiment 1

[0041] Prepare the honeycomb substrate. It should be noted that the honeycomb substrate is made of cordierite and has a volume of 2 liters. In addition, the honeycomb substrate contained cells in an amount of 300 cells / square inch, and had an average pore diameter of 25 micrometers and a porosity of 65% by volume. In addition, the honeycomb substrate is used in DPF applications and contains gas permeable porous walls. However, the honeycomb base material is completely free of embolization, so the honeycomb channels form a straight-running structure of the honeycomb structure. The honeycomb base material is immersed in alumina sol with nanoscale primary particle size. Then, the honeycomb substrate was taken out from the alumina sol and blown with air to blow off excess alumina sol. Thereafter, the honeycomb substrate was dried at 120°C and further calcined at 500°C for 2 hours. Thus, an alumina coating is formed on and within the honeycomb substrate. It should be noted tha...

Embodiment 2

[0054] The catalyst was prepared in the same manner as in Comparative Example 1, except that a coating was formed in an amount of 200 grams per 1 liter of volume of the honeycomb substrate; along the exhaust gas flow direction, the catalyst was arranged upstream of the catalyst in Example 1 side. The combination of the obtained catalyst and the catalyst of Example 1 is designated as the catalyst of Example 2 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com