H-beam steel straightening machine frange plate perpendicularity detection apparatus

A detection device and verticality technology, applied in the direction of measuring devices, instruments, using wave/particle radiation, etc., can solve the problems of insufficient monitoring and the inability to detect the connection status of web and flange plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

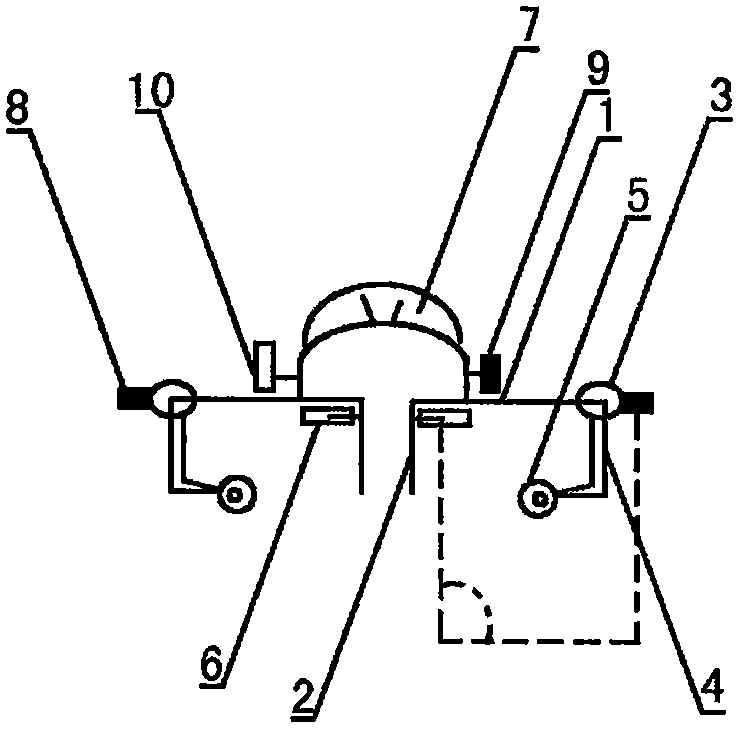

[0012] Embodiment: as shown in the accompanying drawing. The detection device for the verticality of the flange plate of the H-shaped steel leveling machine includes a frame body (1), the main part of the frame body (1) is a T-shaped positioning clamping frame (2), and length adjusters (3) of equal structure are arranged on both sides , connecting rod (4), guide wheel device (5), the upper part of the frame body (1) is provided with a ray emitting device (6), an indicating device (7), and the frame body (1) is installed above the H-shaped web during operation, and the ray After being refracted, it is captured by the sensing device (8), and the detection value is analyzed by the central control device (9), and the verticality of the flange plate is visually expressed.

[0013] The verticality detecting device of the flange plate of the H-shaped steel leveling machine is equipped with a prompting device (10), and a corresponding prompting message is sent out when the detected va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com