Strengthened concrete column structure with anticorrosion and anti-fire functions

A concrete column and concrete technology, applied in fire protection, building components, building structures, etc., can solve problems such as insufficient anti-corrosion measures, building corrosion, and insufficient durability, and meet safety protection requirements, good earthquake resistance, and durability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

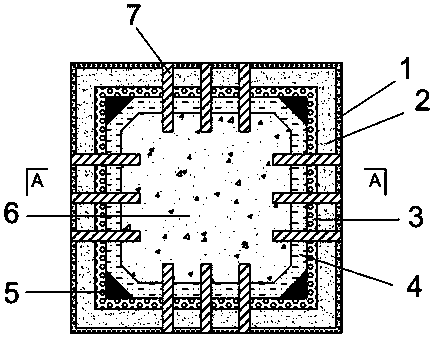

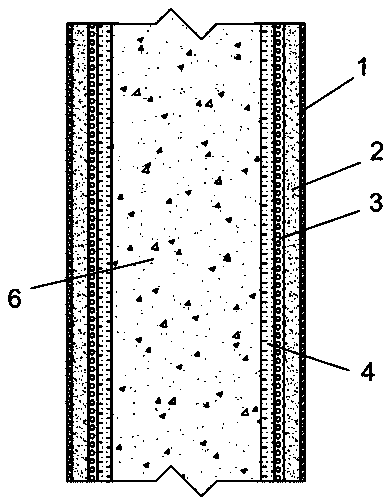

[0018] Such as figure 1 and figure 2 As shown, the reinforced concrete column structure with both anti-corrosion and fire-proof functions mainly includes sealing mortar 1, high-strength crack-resistant and impermeable shell 2, barrier fireproof material 3, rock wool board 4, fixed rib 5, and fiber-reinforced concrete 6 and shear pin 7, in the reinforced concrete column structure with both anti-corrosion and fire-proof functions, sealing mortar 1, high-strength crack-resistant and impermeable shell 2, barrier fire-proof material 3, rock wool are arranged in sequence from the outer layer to the inner layer Board 4, concrete 6 filled with fiber-reinforced material; fixed ribs 5 are provided at the four corners where the barrier fireproof material 3 and rock wool board 4 meet; The impervious shell 2 improves the stability and strength of the overall structure; the barrier fireproof material 3 can effectively slow down the heat transfer; the rock wool board 4 gives full play to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com