Circuit board component separation equipment and utilization method thereof

A technology for separating equipment and components, used in welding equipment, metal processing equipment, auxiliary devices, etc., to achieve the effect of fast speed, sufficient separation, and classification and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

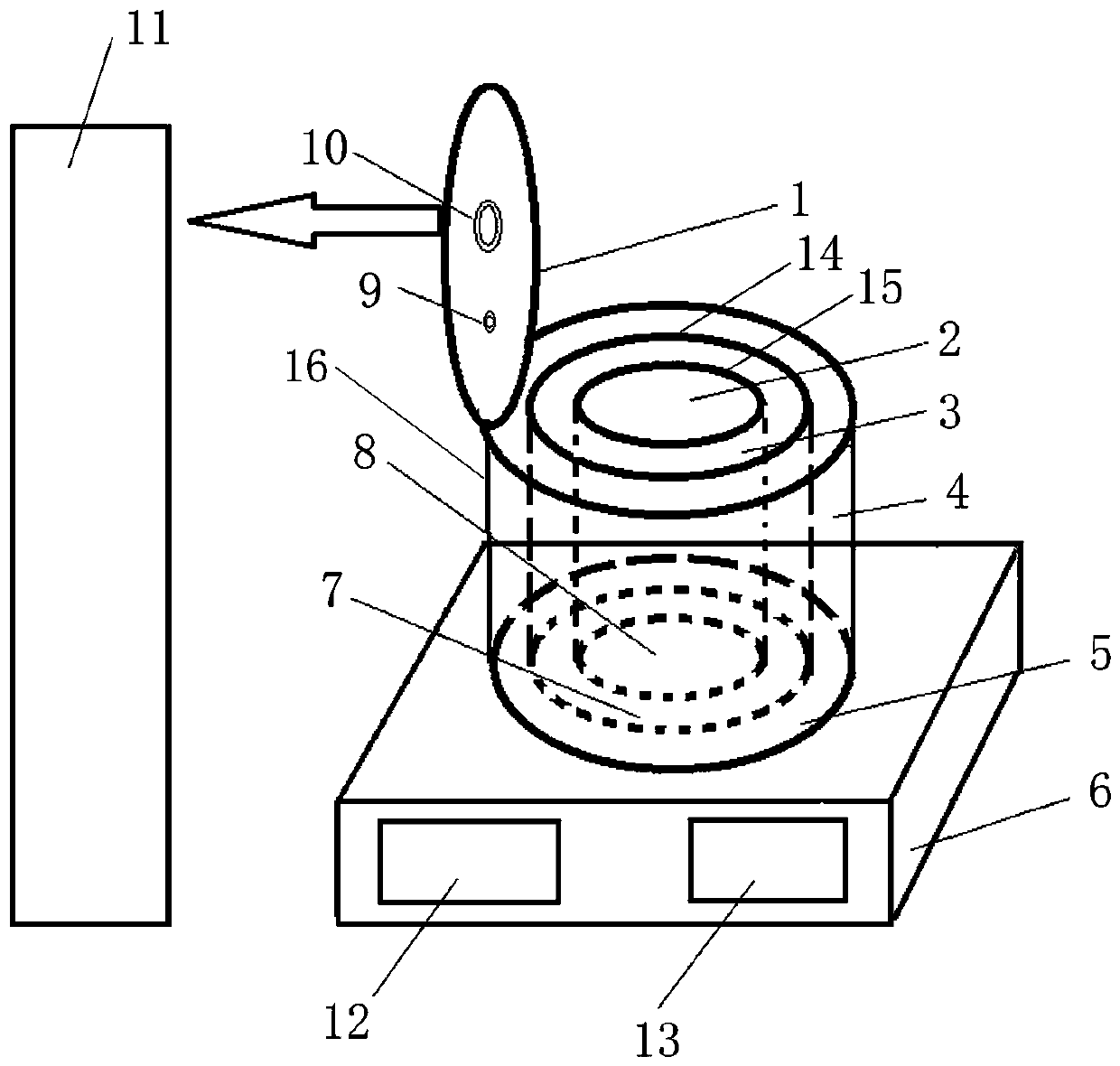

[0025] See attached figure 1 It is an embodiment of the present invention.

[0026] A circuit board component separation device, comprising a separation body 6 and a recovery bin body located above the separation body 6, the separation body 6 is respectively provided with a component storage room 12, a tin container 13, a drive mechanism, Heating temperature control mechanism and control system, the interior of the recovery bin 16 is respectively provided with a cylindrical first metal mesh 15 and a second metal mesh 14 from the inside to the outside, and the mesh diameter of the first metal mesh 15 is larger than the Describe the second metal mesh 14, the inner side of the first metal mesh 15 is used as the raw material bin 2, and the waste solid channel and the condensation pipe are respectively arranged under the raw material bin 2, and the condensation recovery device 11 is connected to the condensation pipe. A metal mesh 15 and the second metal mesh 14 are used as a comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com