A Quasi-Fluid Rapid Forming Method for Martensitic Steel Complex Tubular Structural Parts

A martensitic steel and complex tube technology, applied in the field of advanced manufacturing of metal complex structural parts, can solve the problems of low technology and device requirements, low forming efficiency, etc., to reduce blank loss, decrease wall thickness reduction rate, The effect of increasing the intensity level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

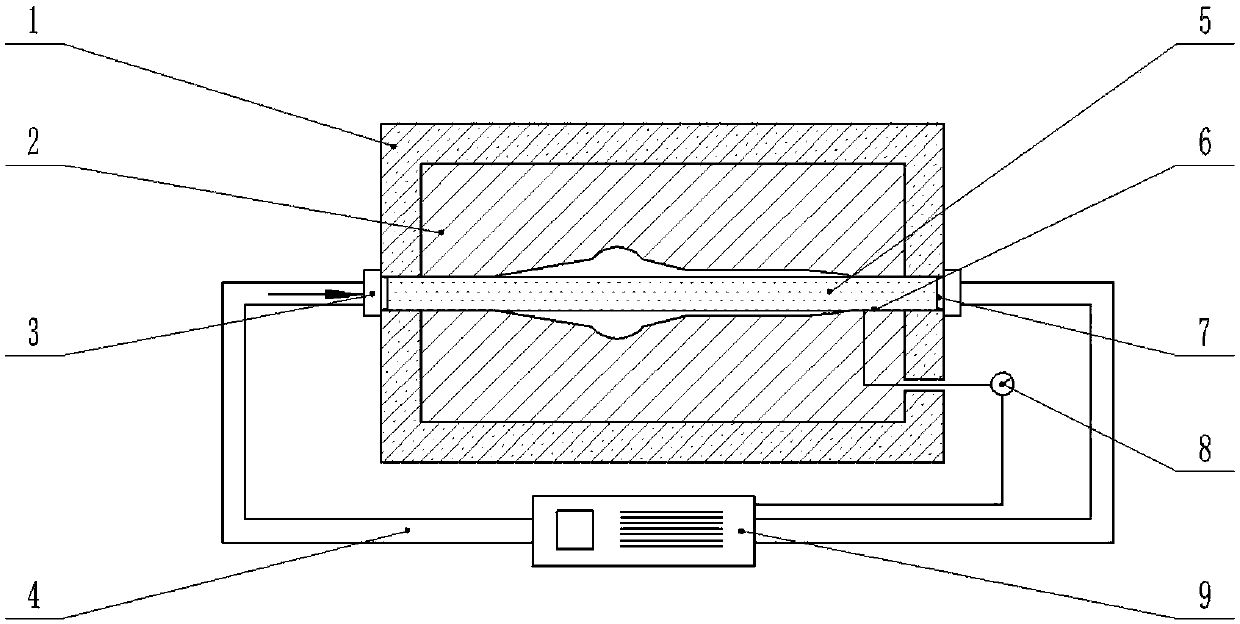

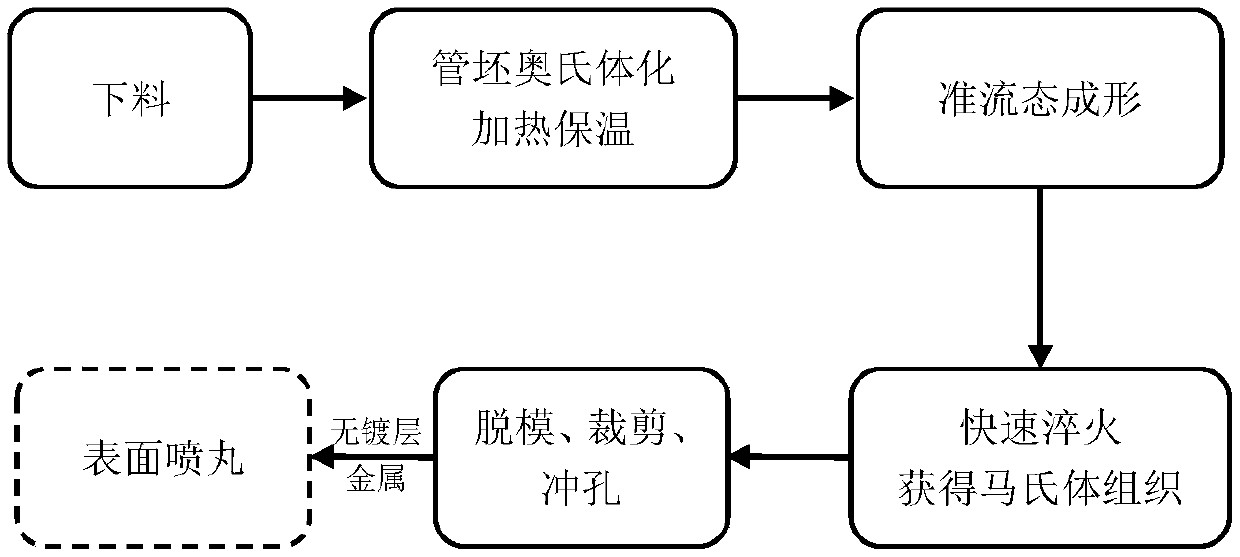

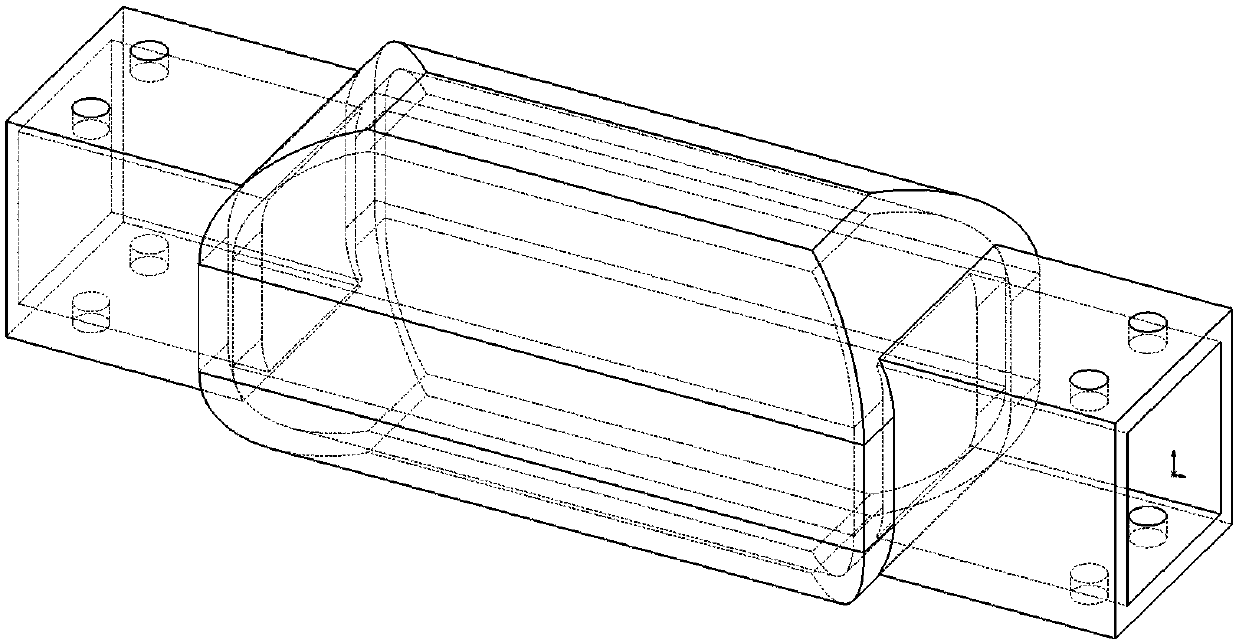

[0035] Embodiment 1: with reference to attached figure 1 , 2 , 3, a quasi-fluid rapid prototyping method and device for a martensitic steel complex tubular structure, comprising the following steps:

[0036] 1) Cutting: Select a square-edged 22MnB5 uncoated ultra-high-strength steel tube blank with an outer diameter of 20mm and a wall thickness of 3mm, and cut the tube blank to an axial length of 75mm;

[0037]2) Austenitization: Place the cut tube blank in a resistance furnace and heat it to 920°C as a whole, and then keep it warm for two minutes; during the heating process, segmental heating is used, and the heating temperature of each section is 320°C, 610°C, 920°C ℃, the pipe needs to be rotated 90° before each section is heated into the furnace to ensure that it is evenly heated; the heating temperature is monitored by the temperature monitoring device 8;

[0038] The advantages of adopting segmental heating in the present invention are: the heating speed of the ordinar...

Embodiment 2

[0044] Embodiment 2: with reference to attached figure 1 , 2 , 4, a quasi-fluid rapid prototyping method and device for a martensitic steel complex tubular structure, comprising the following steps:

[0045] 1) Cutting: Select a square-edged 30MnB5 uncoated ultra-high-strength steel tube blank with an outer diameter of 12mm and a wall thickness of 2mm, and cut the tube blank to an axial length of 60mm;

[0046] 2) Austenitization: Place the cut tube blank in a resistance furnace and heat it to 930°C as a whole, and then keep it warm for two minutes; during the heating process, segmental heating is used, and the heating temperature of each section is 330°C, 620°C, 930°C respectively. ℃, the pipe should be rotated 90° before each section is heated into the furnace to ensure that it is evenly heated;

[0047] 3) Quasi-fluid forming: After heating, use the mechanical arm to quickly put the tube blank into the forming mold, and after the punches at both ends are clamped, use AZB3...

Embodiment 3

[0051] Embodiment 3: with reference to attached figure 1 , 2 , Shown in 5, a quasi-fluid rapid prototyping method and device for a martensitic steel complex tubular structure, comprising the following steps:

[0052] 1) Cutting: Select a cylindrical 30CrMnSiA ultra-high-strength steel tube billet with an outer diameter of 20 mm and a wall thickness of 2 mm with Al-Si coating, and cut the tube billet to an axial length of 70 mm;

[0053] 2) Austenitization: Place the cut tube blank in a resistance furnace and heat it to 950°C as a whole, and then keep it warm for two minutes; during the heating process, segmental heating is used, and the heating temperature of each section is 350°C, 640°C, 950°C, respectively. ℃, the pipe should be rotated 90° before each section is heated into the furnace to ensure that it is evenly heated;

[0054] 3) Quasi-fluid forming: After heating, use the mechanical arm to quickly put the tube blank into the forming mold, and after clamping the punche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com