Aluminum profile extrusion die cleaning and waste water recycling device

An extrusion die and waste water recycling technology, applied in the field of aluminum profile forming, can solve the problems of low Al recovery rate and NaOH addition, and achieve the effect of improving the reaction rate and cleaning with zero dead ends.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

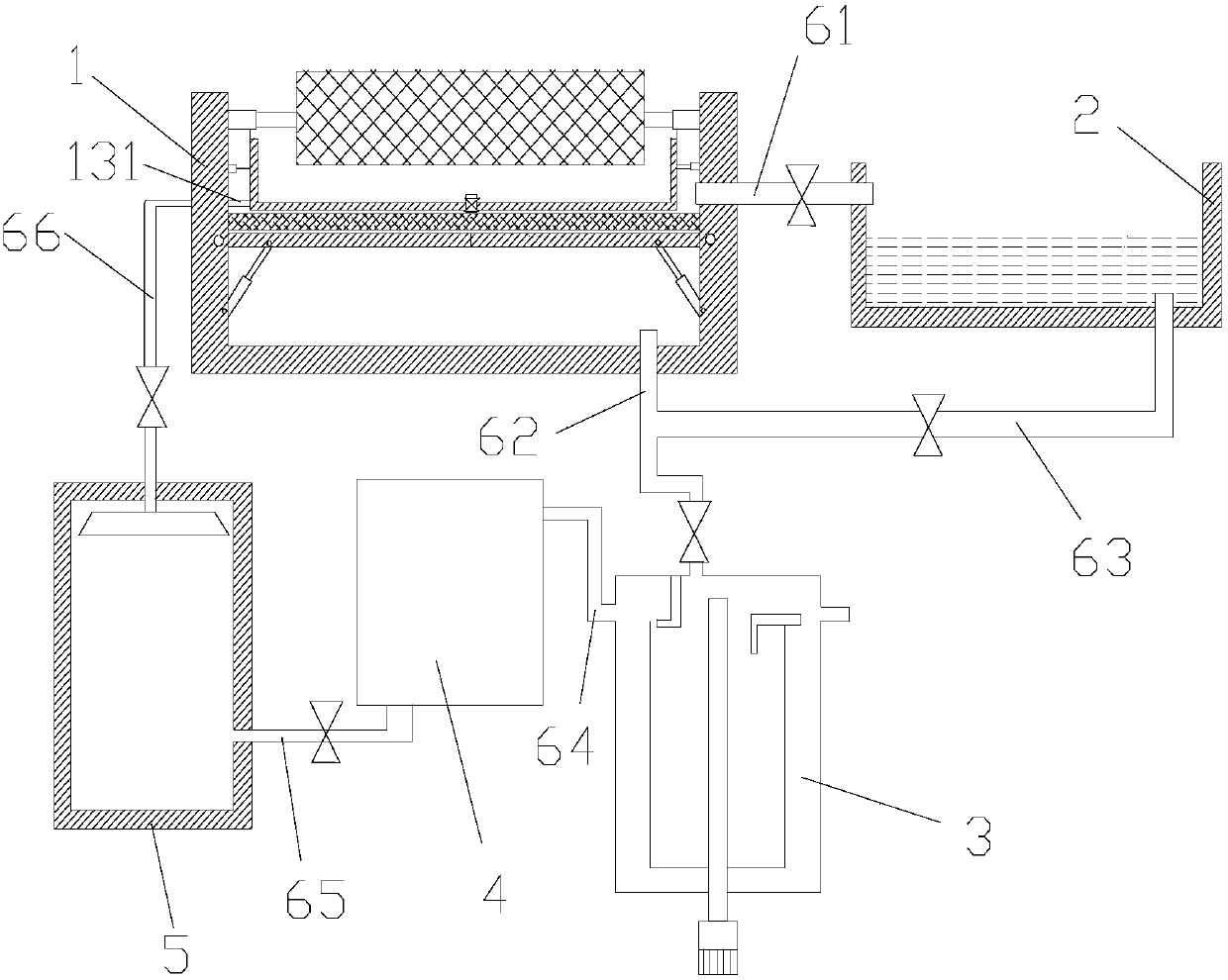

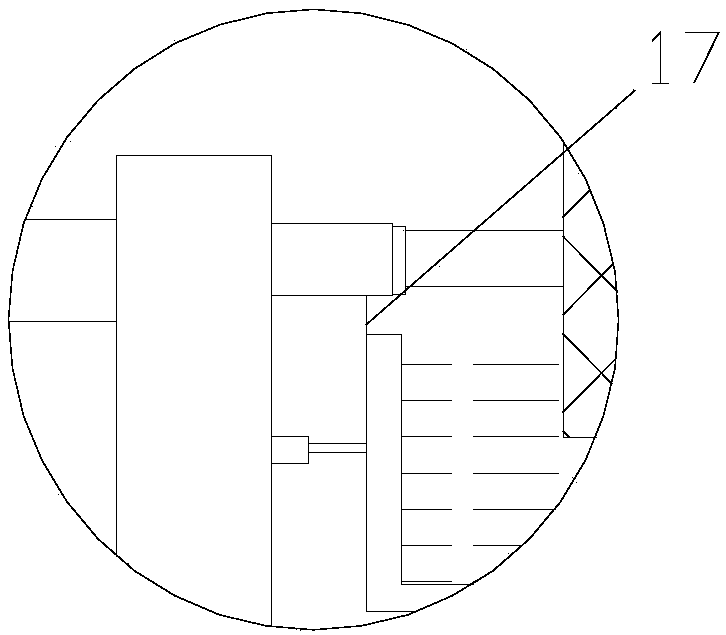

[0070] Such as figure 1 , 5 As shown, the difference between this embodiment and the above-mentioned embodiments is that a steam recovery cover is arranged above the inner cavity of the heating box 5 . Both the shaking tank 13 and the reaction tank 2 are sandwich structures. A first heat preservation pipe 131 and a second heat preservation pipe 21 are respectively arranged in the interlayer of the oscillation tank 13 and the reaction pool 2 . The first heat preservation pipe 131 and the second heat preservation pipe 21 are respectively wound in the interlayer of the oscillation tank 13 and the reaction pool 2 in a spiral shape from bottom to top. Wherein, the inlet of the first heat preservation pipe 131 communicates with the steam recovery cover through the sixth pipeline 66 , and the outlet of the first heat preservation pipe 131 communicates with the second heat preservation pipe 21 through the seventh pipeline (not shown in the figure).

[0071] In the present invention...

Embodiment 3

[0074] The present invention also discloses a method for aluminum recovery and treatment using the above-mentioned aluminum profile extrusion die cleaning and waste water recovery treatment device, which includes the following steps:

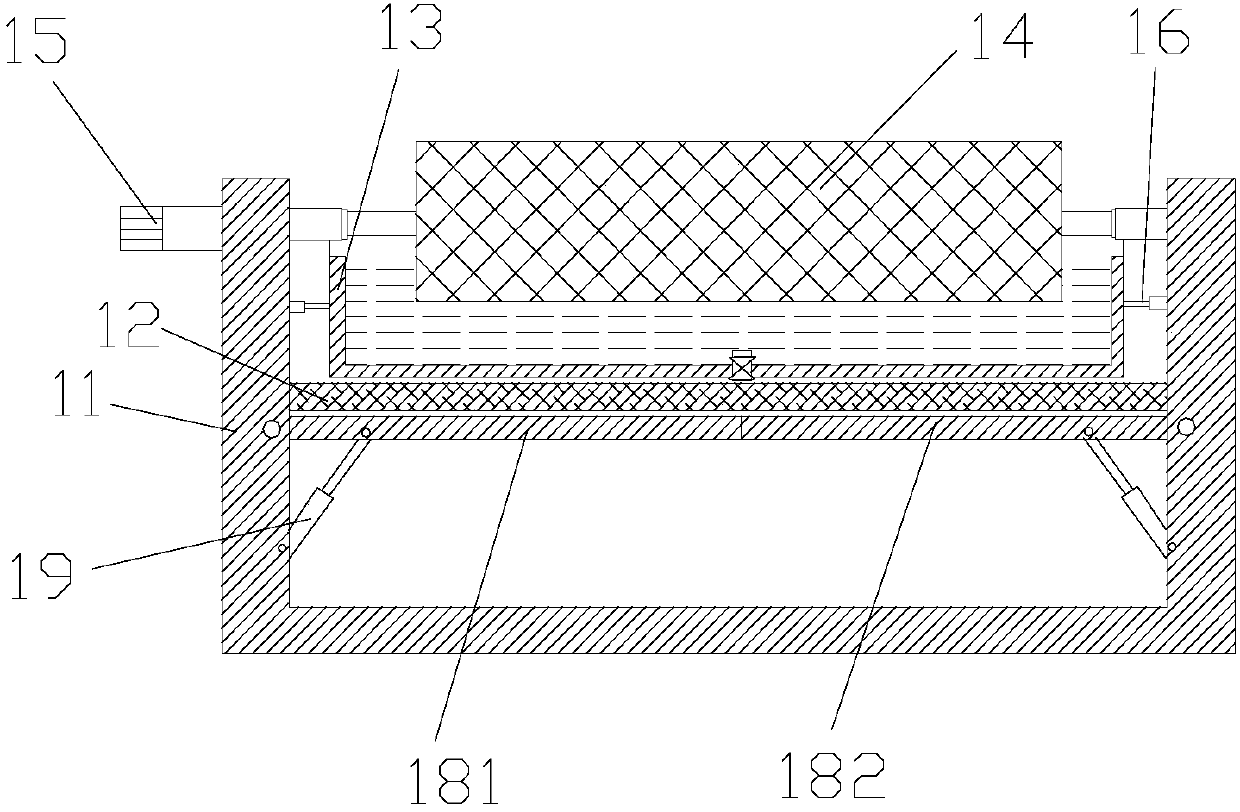

[0075] (1) Place the aluminum profile extrusion die in the housing net cylinder 14, add alkali washing liquid into the oscillation tank 13, so that the lower cylinder part of the housing net cylinder 14 is immersed in the alkali washing liquid, and pass through the oscillation tank 13 The heating tube in the boiler heats the alkaline washing solution.

[0076] (2) Drive the first motor 15 to drive the storage net cylinder 14 to rotate, and at the same time push the oscillation tank 13 to swing through the pushing mechanism to carry out alkali cleaning on the mold.

[0077] (3) After alkali washing, open the valve and filter the alkali washing liquid after alkali washing. where NaAlO 2 The solution permeates into the lower chamber through the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com