A pin-type double-cone truncated sand mill device

A frustum-shaped, sand mill technology, applied in the direction of grain processing, etc., can solve the problems that cannot meet the temperature requirements of heat-sensitive materials, the sanding efficiency needs to be improved, and affect the service life of the main shaft, so as to save energy consumption and reduce maintenance work. , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be described below in conjunction with the drawings.

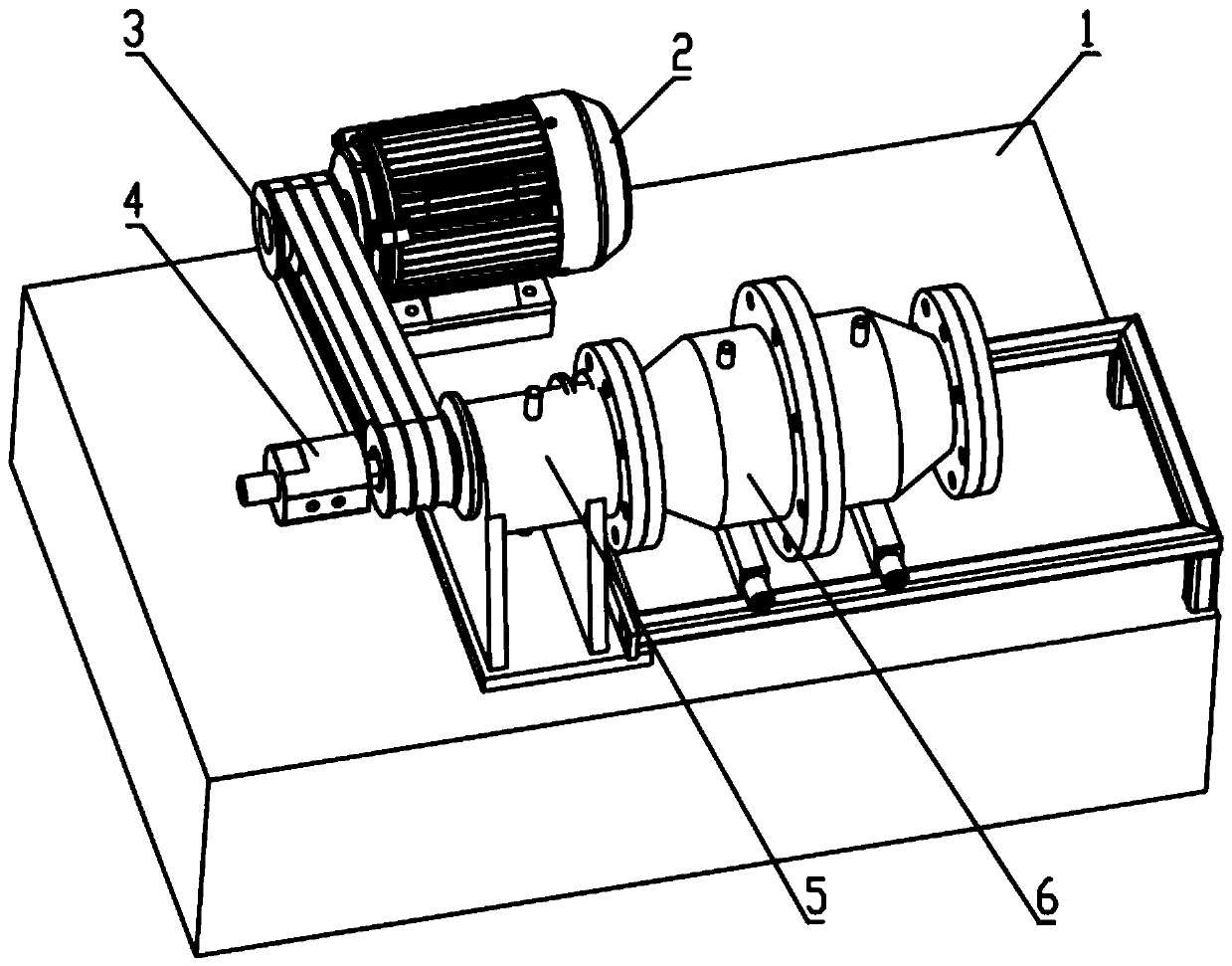

[0038] Such as figure 1 As shown, the pin-type double cone-shaped sand mill device of this embodiment includes a frame 1, a motor 2 is installed on the upper surface of the frame 1, and the output end of the motor 2 is connected to a spindle part 4 through a transmission part 3. One end of 4 is supported by the bearing base part 5, and the outer end of the bearing base part 5 is installed with the sanding barrel part 6 through a sealing device. The sanding barrel part 6 is equipped with an agitator 7 connected to the main shaft part 4. Rollers 801 are provided on both sides of the sanding barrel part 6, and a rail frame 8 running by the rollers 801 is installed on the upper surface of the frame 1.

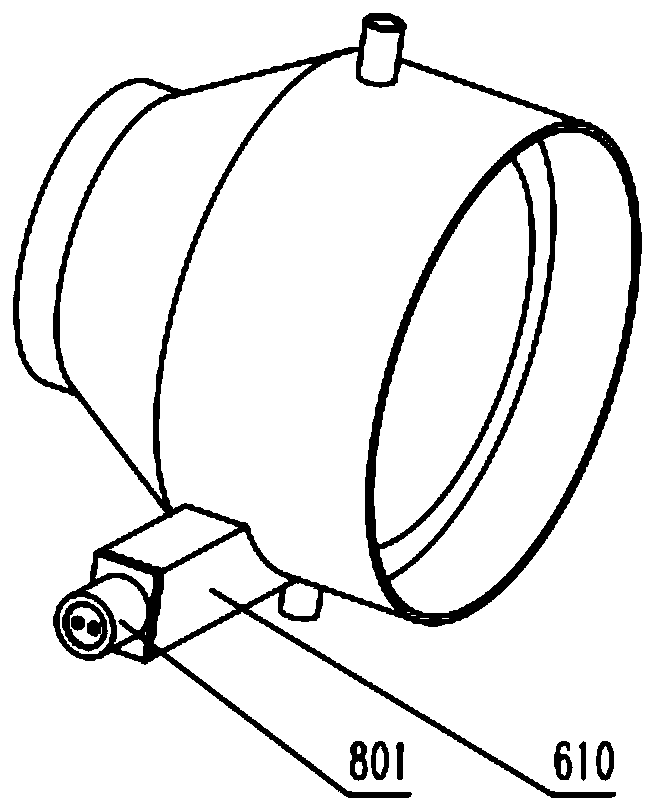

[0039] The structure of the sanding barrel part 6 is as follows: a left barrel body 601 and a right barrel body 605 are symmetrically arranged. The intermediate connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com