Food-grade silicon production method

A production method and food-grade technology, applied in the field of food-grade silicon production, can solve the problem of harmful substances entering and achieve the effect of easy absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

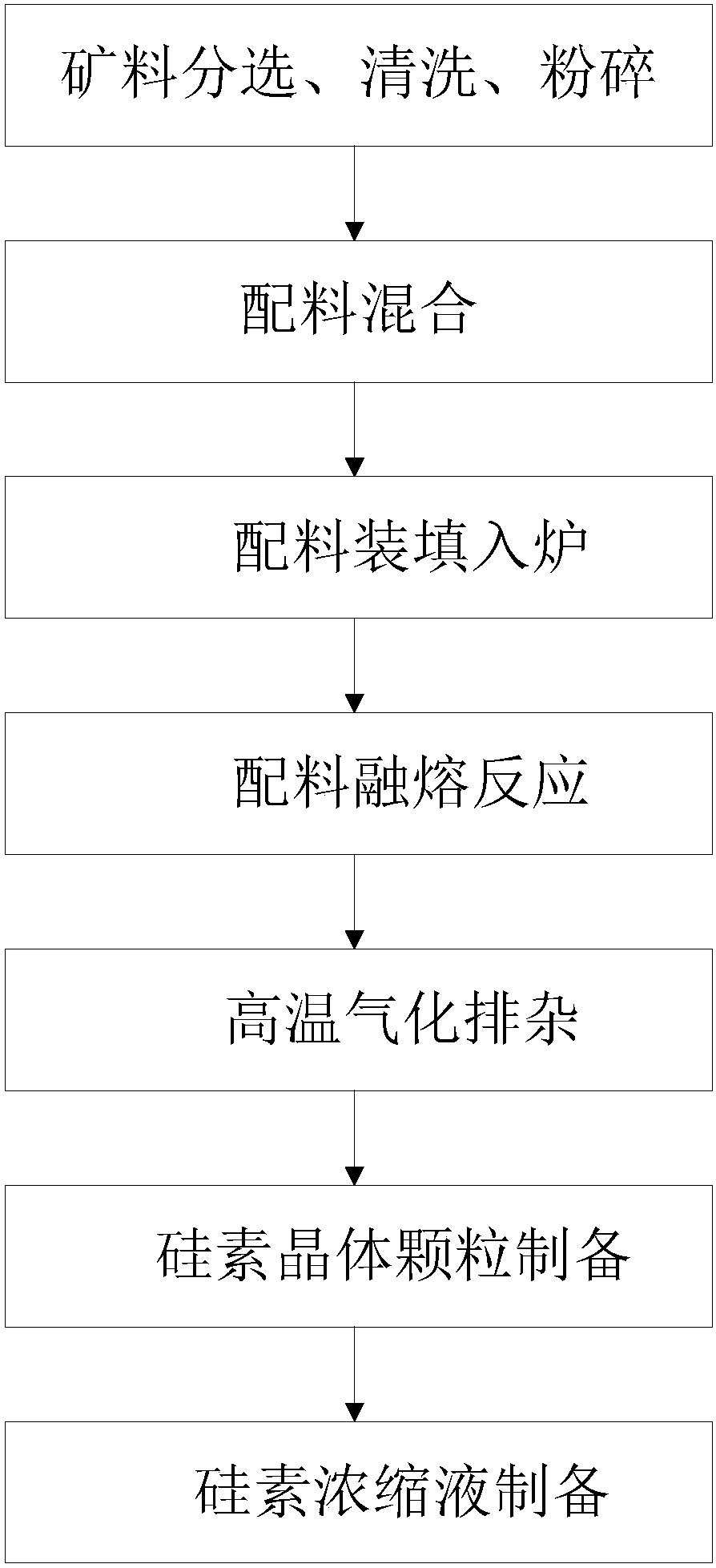

[0028] As attached to the manual figure 1 As shown, embodiments of the present invention include:

[0029] Provide a kind of production and manufacturing process of food-grade silicon, it is characterized in that comprising the following steps:

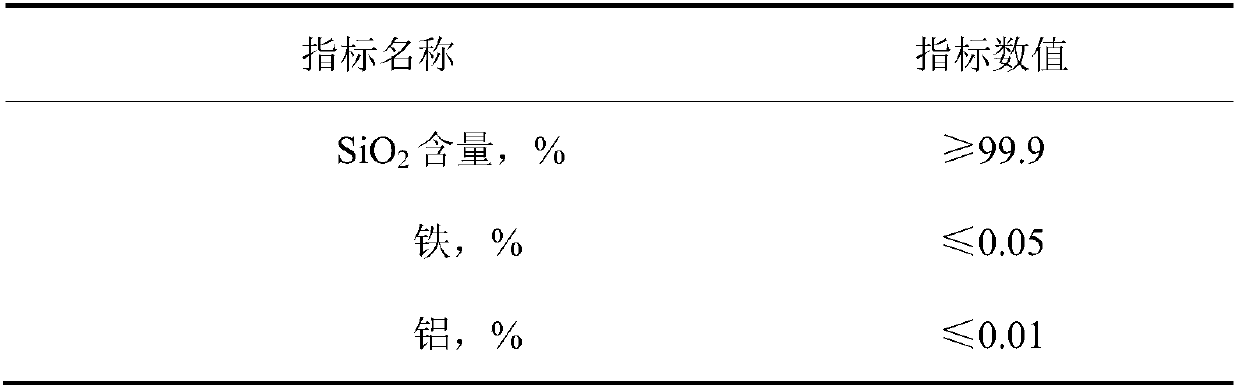

[0030] The first step is mineral material sorting, cleaning and crushing: in the clean workshop, high-purity natural quartz stone (≥99.9%) is sorted from natural quartz stone, soaked in high-purity water, ultrasonically cleaned, dried, and crushed to 80-200 head;

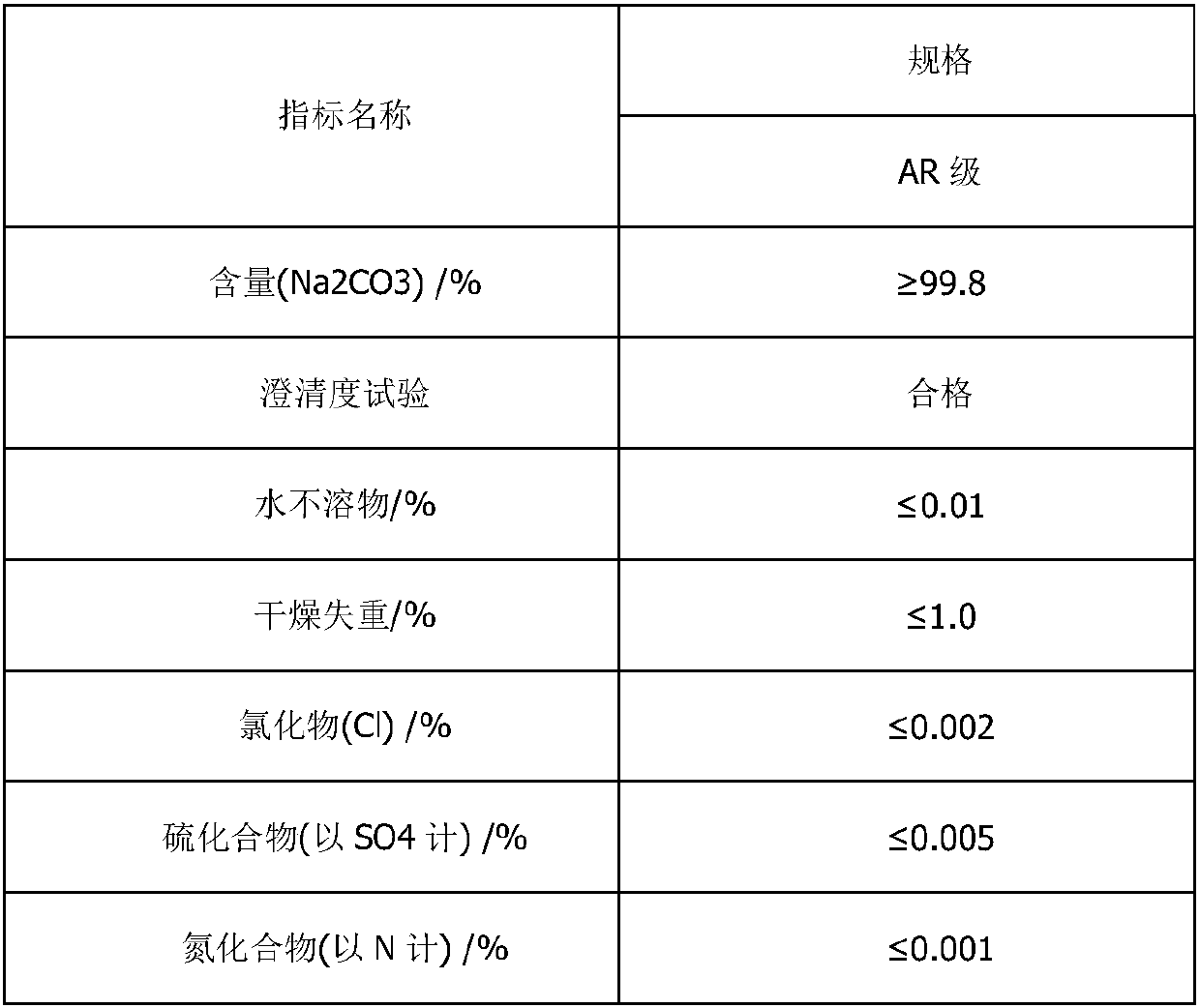

[0031] Second step, batching mixing: above-mentioned quartz powder and food-grade soda ash (total alkali amount is with Na 2 CO 3 ≥ 99.8%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com