Machine and pump integrated submersible direct drive screw pump oil extraction device and method

A technology for oil production equipment and screw pumps, which is applied in the direction of pumps, pump components, and production fluids, etc. It can solve the problems of poor unit passability, low productivity of a single well, and inability to trip and repair wells, so as to reduce one-time investment and maintenance Strong adaptability to cost and well conditions, and the effect of improving passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

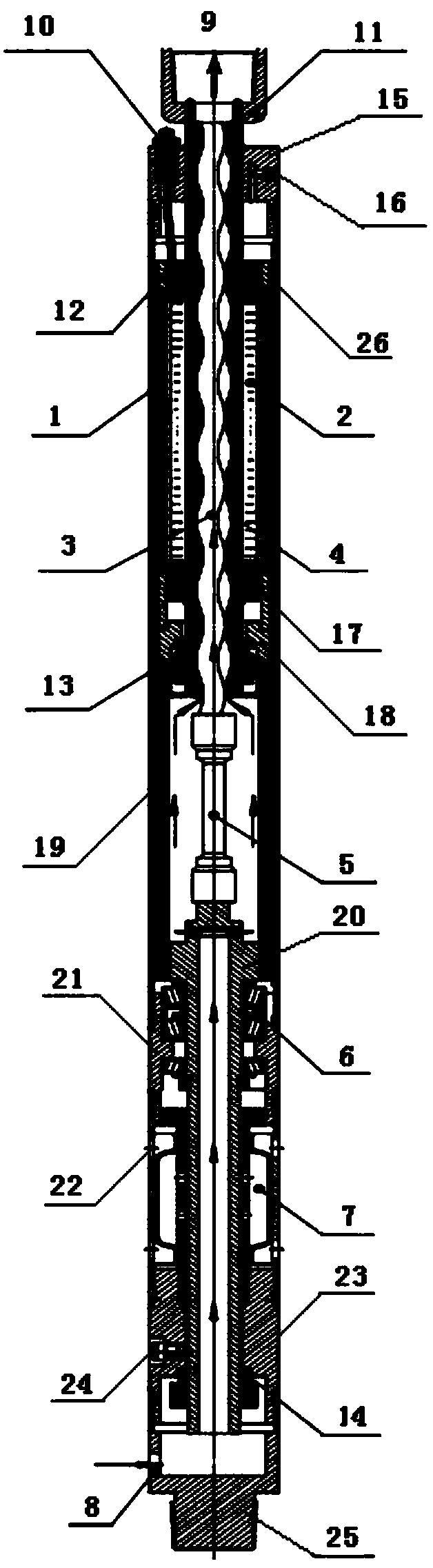

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0023] see figure 1 , the machine-pump integrated submersible direct-drive screw pump oil production device includes a casing 26, the upper end of the casing 26 is connected with an upper head 15, the upper head 15 is provided with an air outlet 16, and the casing 26 is provided with a motor rotor 1, the said The motor rotor 1 is connected to the power supply device through the cable 10, and the upper head 15 is provided with a threading hole for the cable 10 to pass through. The lower end is connected with a blocking member 18, the lower end of the blocking member 18 is connected with a transmission cylinder 19, the inside of the blocking member 18 is provided with a first mechanical seal 13, the inside of the transmission cylinder 19 is provided with a flexible shaft 5, and the lower end of the flexible shaft 5 is connected with a transmission joint 20, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com