Down-the-hole drill

A down-the-hole drilling rig and drilling rig technology are applied in earthwork drilling, drilling equipment, drilling equipment and methods, etc., which can solve the problems of low drilling efficiency, large volume, and inconvenient movement of the roller cone drilling rig, and achieve Solve the effect of not being able to drill into large-aperture blastholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

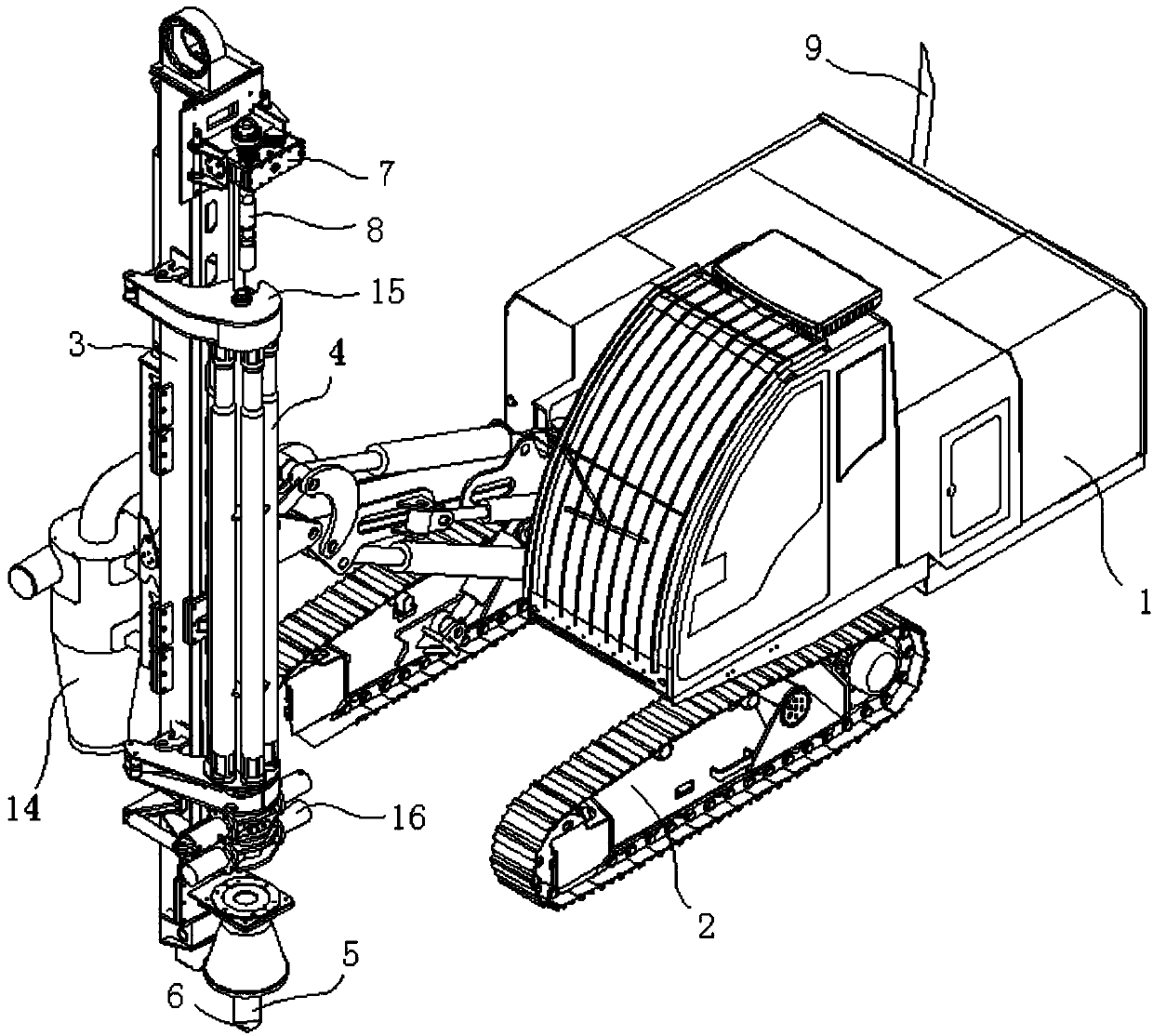

[0024] See Figure 1 to Figure 4 , Figure 1 to Figure 4 A specific embodiment of a down-the-hole drill of the present invention is provided, wherein: figure 1 It is a schematic diagram of the overall structure of the down-the-hole drill disclosed in Embodiment 1 of the present invention; figure 2 It is an enlarged schematic diagram of the down-the-hole drilling machine A disclosed in embodiment 1 of the present invention; image 3 It is an enlarged schematic diagram of the upper end of the drill stand disclosed in Embodiment 1 of the present invention; Figure 4 This is an enlarged schematic diagram of the lower end of the drill stand disclosed in Embodiment 1 of the present invention.

[0025] Such as Figure 1 to Figure 4 As shown, the present invention provides a down-the-hole drilling rig, which can effectively realize the drilling of large-diameter blastholes above 250 mm. The down-the-hole drilling rig includes a drilling rig body 1, a traveling mechanism 2, a drill fram...

Embodiment 2

[0046] Example 2: see Figure 5 , Figure 5 Another embodiment of a down-the-hole drilling machine of the present invention is provided, wherein: Figure 5 It is a schematic diagram of the overall structure of the down-the-hole drill disclosed in Embodiment 2 of the present invention.

[0047] Such as Figure 5 As shown, in this embodiment, a swing arm mechanism 17 is provided between the drill body 1 and the drill frame 3, and the swing arm mechanism 17 is used to adjust the angle between the drill frame 3 and the working ground.

[0048] Figure 5 In this case, the swing arm mechanism 17 controls the drill frame 3 to rotate at a proper angle, so that the drill frame 3 deviates from the original vertical state. In this way, it overcomes the defect that the traditional drilling rig can only drill into the blasthole on the horizontal ground and makes the Down-the-hole drills can also drill holes on slopes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com