Improved nasonry knife

The utility model relates to a technology for plastering knives and plastering tiles, which is applied in the field of plastering knives, and can solve the problems of inaccurate placement, cumbersome operation, easy spillage of cement, etc., and achieve the effects of lightening the workload, beautiful wall structure, and convenient construction operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

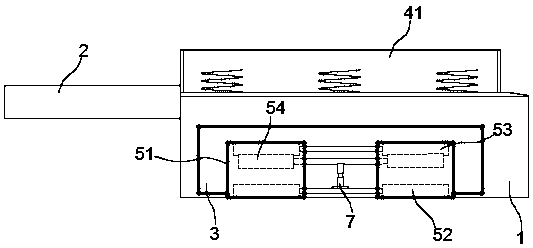

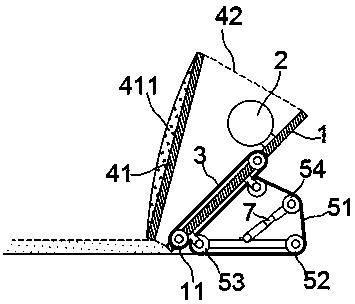

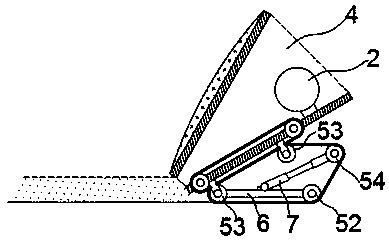

[0018] exist Figure 1 to Figure 3 In the shown embodiment, the improved masonry knife includes a knife plate 1 and a knife handle 2;

[0019] Two drive rollers 11 are embedded on the knife plate 1, the drive rollers 11 are parallel to the bottom edge of the knife plate 1, and a transmission belt 3 is installed between the two drive rollers 11, and the transmission belt 3 is connected from the knife plate The sides of 1 are exposed;

[0020] On one side of the knife plate 1, a collecting hopper 4 is fixedly arranged, and the outlet of the collecting hopper 4 is parallel to the bottom edge of the knife plate 1; the collecting hopper 4 includes a hard baffle plate 41 and a quality Soft connecting edge 42, the baffle plate 41 is opposite to the knife plate 1, a rubber layer 411 is attached to the outer surface of the baffle plate 41, and a buffer is installed between the inner plate surface of the baffle plate 41 and the knife plate 1. spring;

[0021] On the other side plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com