Inner hole electroplating device

An electroplating device and inner hole technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of irregular chrome plating transition zone, low chrome plating pass rate, difficulty in manual protection, etc., achieve uniform coating thickness, improve edge quality, and save money The effect of electroplating materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

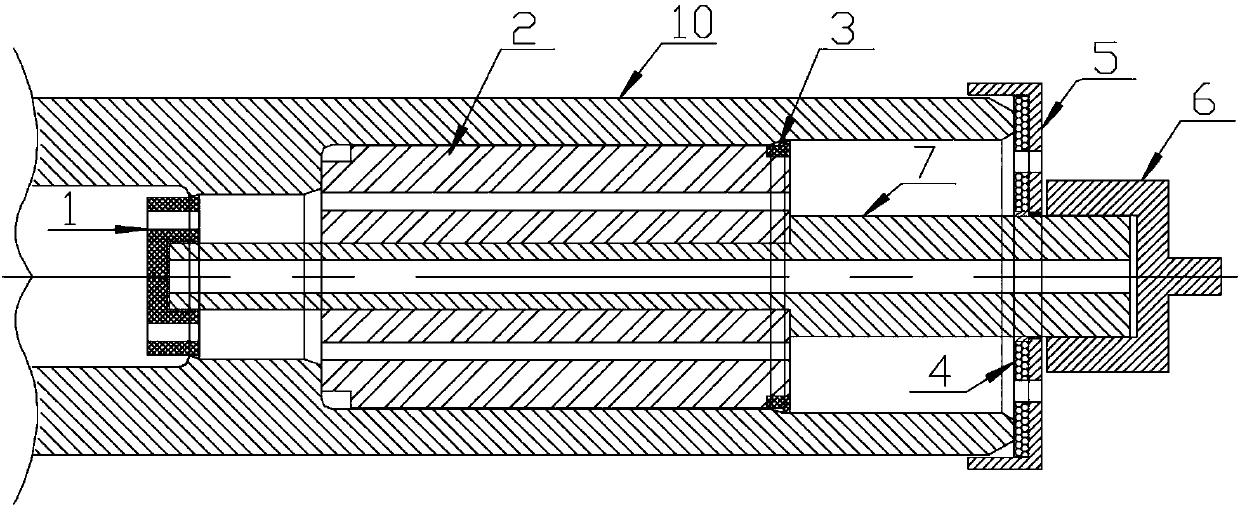

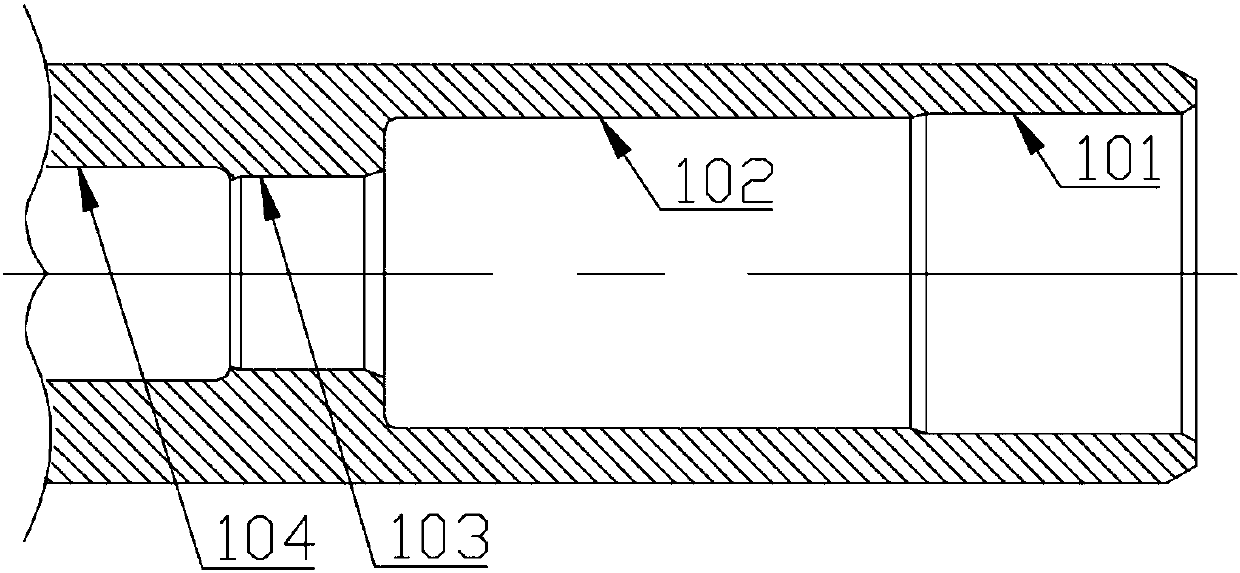

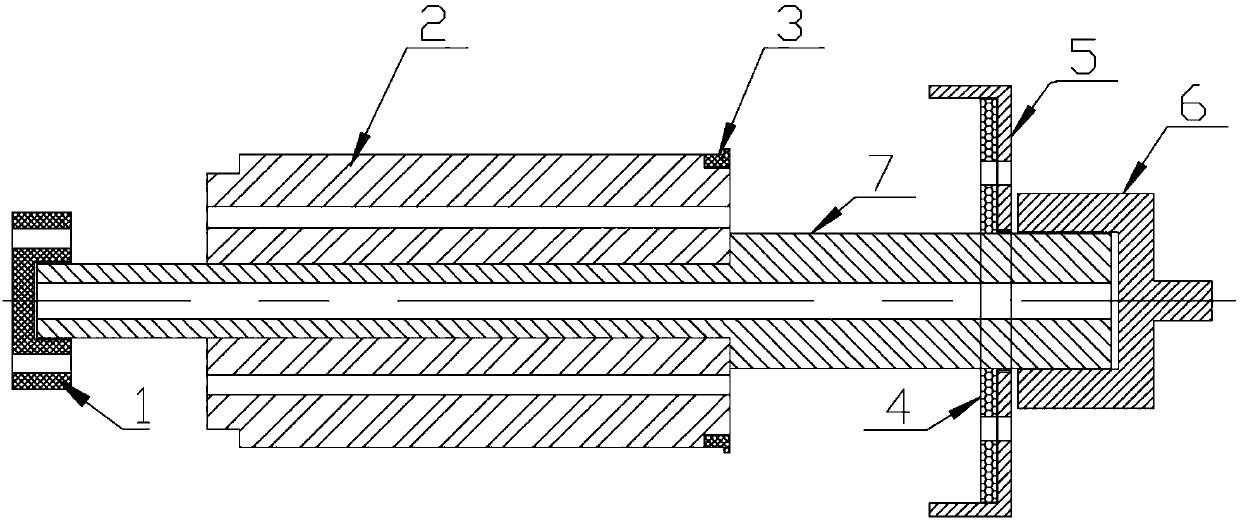

[0033] see Figure 1-10 , the workpiece 10 includes four inner holes: the first inner hole 101, the second inner hole 102, the third inner hole 103 and the fourth inner hole 104, and the first inner hole 101 and the third inner hole The hole 103 is electroplated (the electroplating part of the inner hole), and the inner hole 102 of the second section is not electroplated (the non-electroplating part of the inner hole) as an example. The inner hole electroplating device of the present invention includes an anode rod 7 and a protective sleeve 2 sleeved on the anode rod 7, the second section inner hole 102 of the workpiece 10 is sleeved on the protective sleeve 2, and the anode rod 7 is located on the In the inner hole of the workpiece 10, and there is a gap between the first section of the inner hole 101 and the third section of the inner hole 103 and the anod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com