Paper-making wastewater resource recycling and treating process method and paper-making wastewater resource recycling and treating system device

A technology for recovery and treatment of papermaking wastewater, which is applied in the direction of processing wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of small and medium-sized enterprises that cannot be popularized, high operating costs, and cannot use microorganisms, etc., to achieve Improve resource utilization, protect the environment, and improve convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

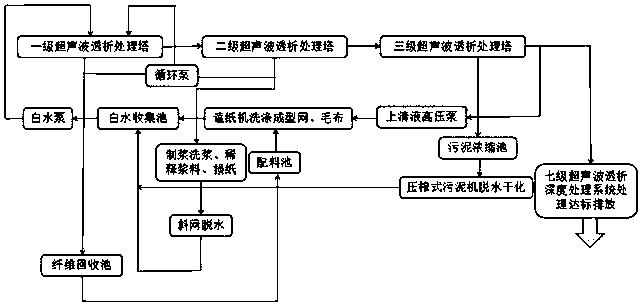

[0028] This embodiment provides a papermaking wastewater resource recovery treatment process and papermaking wastewater resource recovery treatment system equipment corresponding to the papermaking wastewater resource recovery treatment process, and provides the papermaking wastewater resource recovery treatment process and Application of treatment system equipment in paper machine white water wastewater treatment.

[0029] The papermaking wastewater recycling process method of this embodiment comprises the following steps:

[0030] The first step is to collect the papermaking wastewater and perform the first ultrasonic dialysis treatment. After the treatment, the upper and lower parts are separated to obtain the first supernatant and lower fibers, and the lower fibers are put into the papermaking batching pool for recycling;

[0031] In the second step, the first supernatant is collected and subjected to the second ultrasonic dialysis treatment. After the treatment, the upper...

Embodiment 2

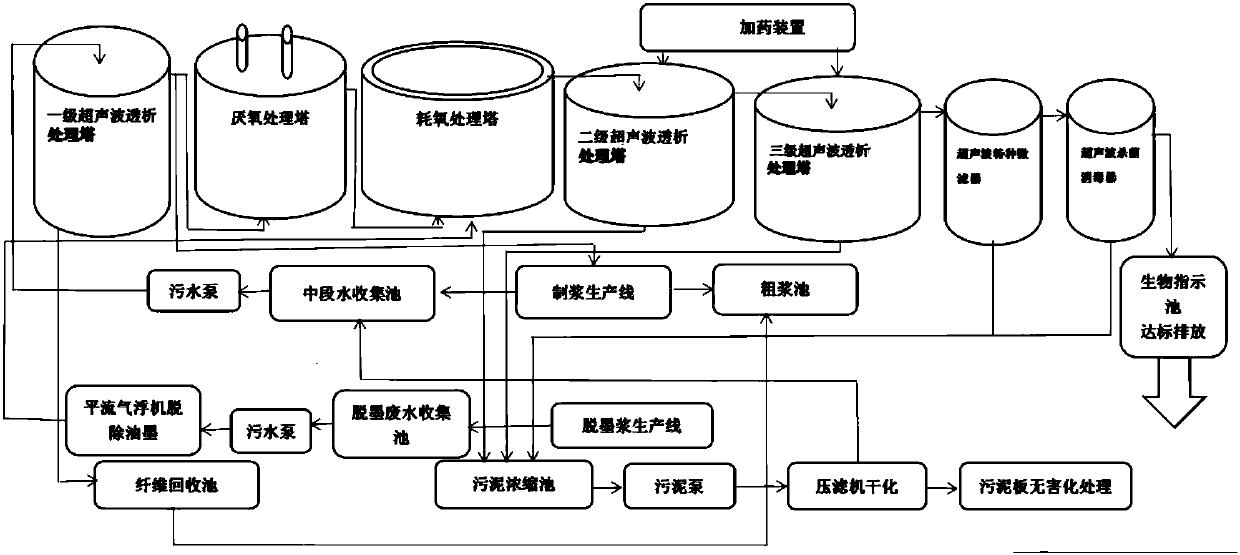

[0043] This embodiment provides a papermaking wastewater resource recovery treatment process and papermaking wastewater resource recovery treatment system equipment corresponding to the papermaking wastewater resource recovery treatment process, and provides the papermaking wastewater resource recovery treatment process and Application of treatment system equipment in middle stage wastewater treatment.

[0044] The papermaking wastewater recycling process method of this embodiment comprises the following steps:

[0045] The first step is to collect the papermaking wastewater and perform the first ultrasonic dialysis treatment. After the treatment, the upper and lower parts are separated to obtain the first supernatant and lower fibers, and the lower fibers are put into the papermaking batching pool for recycling;

[0046] In the second step, the supernatant is collected for the first time and then subjected to anaerobic treatment and aerobic treatment in turn, followed by ultr...

Embodiment 3

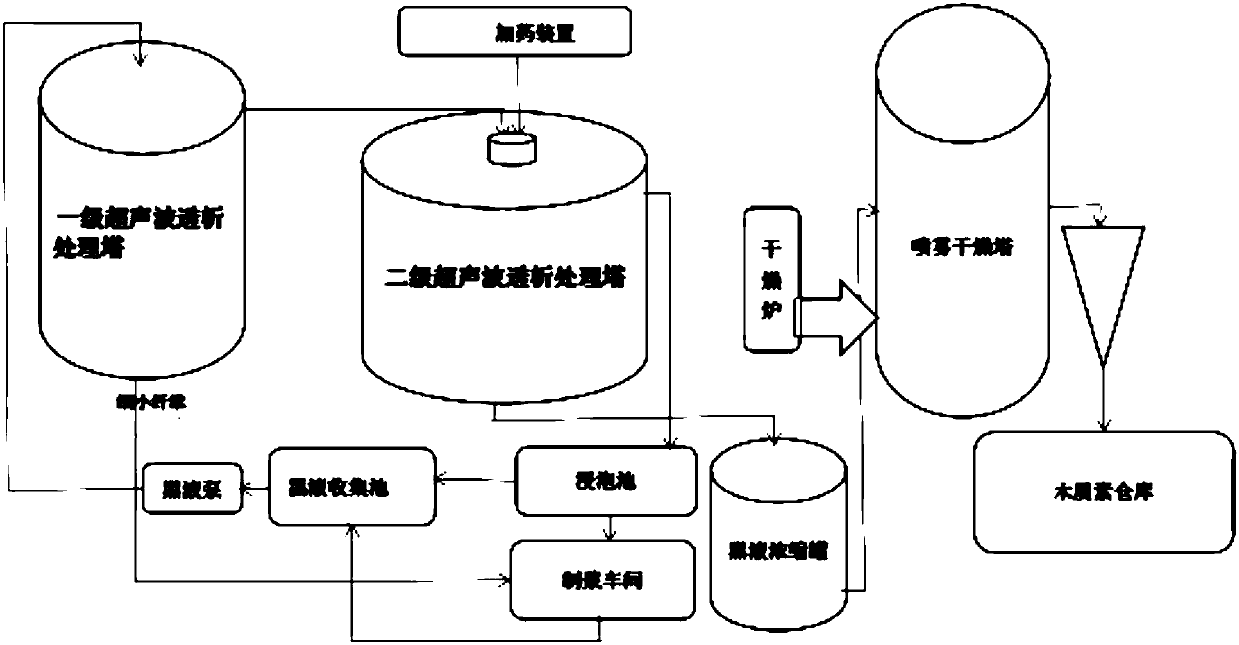

[0056] This embodiment provides a papermaking wastewater resource recovery treatment process and papermaking wastewater resource recovery treatment system equipment corresponding to the papermaking wastewater resource recovery treatment process, and provides the papermaking wastewater resource recovery treatment process and Application of treatment system equipment in pulping black liquor treatment.

[0057] The papermaking wastewater recycling process method of this embodiment comprises the following steps:

[0058] The first step is to collect the papermaking wastewater and perform the first ultrasonic dialysis treatment. After the treatment, the upper and lower parts are separated to obtain the first supernatant and lower fibers, and the lower fibers are put into the pulping workshop for recycling;

[0059] In the second step, the first supernatant is collected and subjected to ultrasonic dialysis treatment for the second time. After the treatment, the upper and lower parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com