Conical air-gap and axial dual-loop type magnetic-field permanent-magnet synchronous motor

A permanent magnet synchronous motor and double-circuit technology, which is applied in the direction of electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve problems such as time-consuming, time-consuming and labor-intensive, and affect mass production, so as to reduce electric heat loss and reduce noise , the effect of saving copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

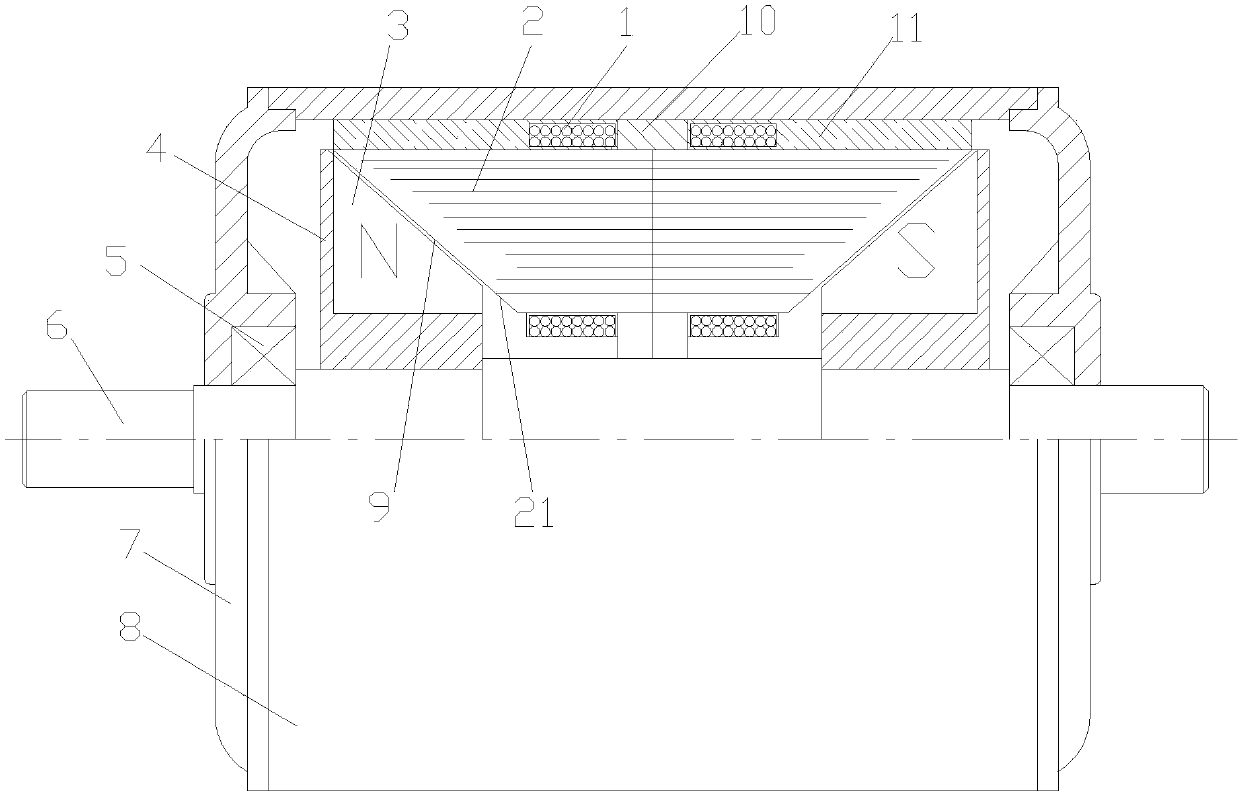

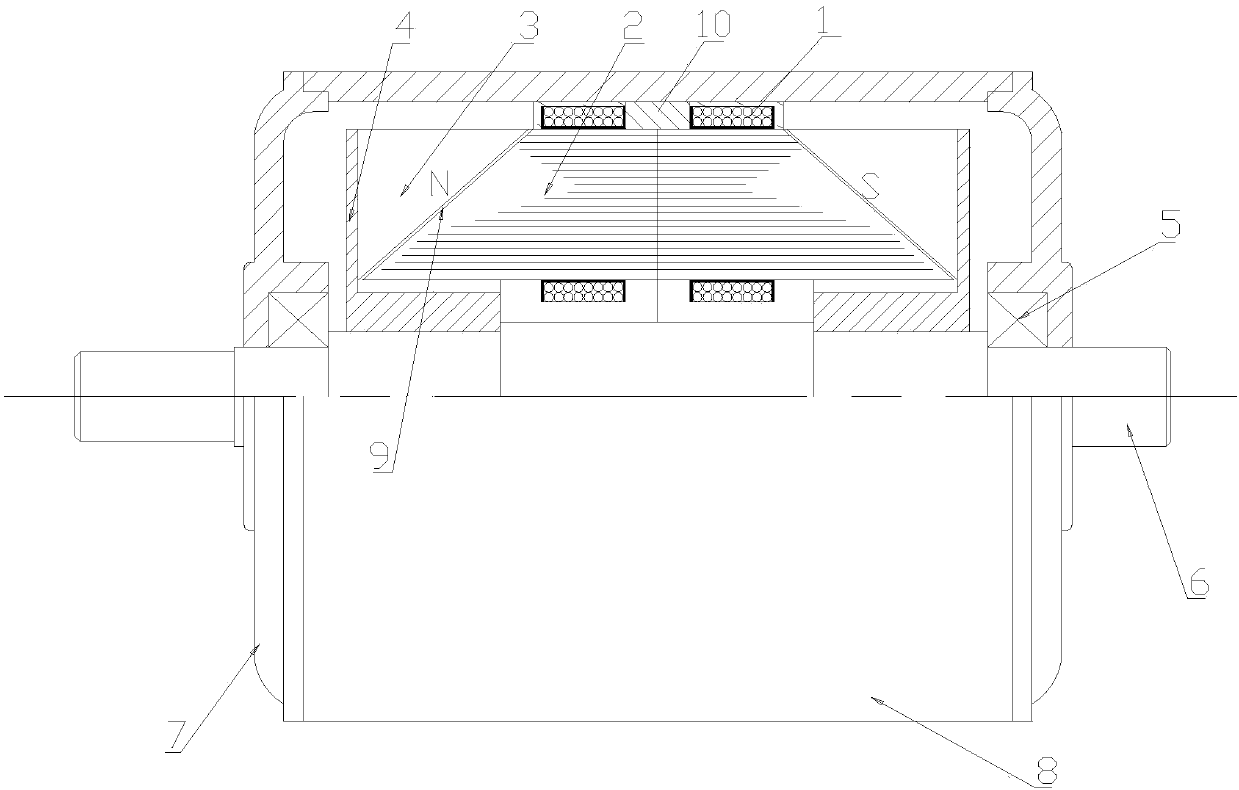

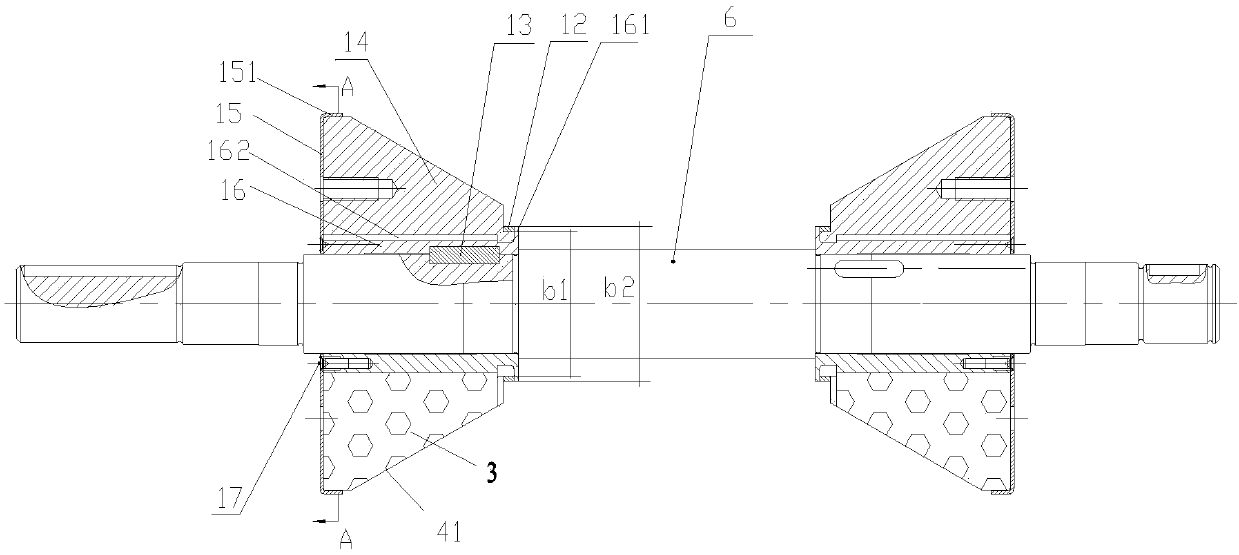

[0036] Figure 1~10 , including stator winding 1, stator core 2, stator tapered surface 21, stator slot portion 22, stator yoke portion 23, stator tooth portion 24, bonding surface 25 of two stator yoke portions, magnetic steel 3, radial Inner end 31, radial outer end 32, first side 33, second side 34, rotor 4, bearing 5, shaft 6, end cover 7, casing 8, tapered air gap 9, positioning ring 10, adhesive 11. Small end ring 12, key 13; check magnetizer 14, hole 141, assembly surface 142, connection surface 143, positioning cover 15, positioning sleeve 151, shaft sleeve 16, shaft sleeve ring 161, positioning groove 162, set screw 17. Stator winding frame 18, etc.

[0037] Such as Figure 1~10 As shown, a tapered air gap axial double-circuit magnetic field permanent magnet synchronous motor includes a casing 8 and a stator core 2 and a rotor 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com