Technical method for improving initial efficiency of lithium ion total battery

A full-battery and lithium-ion technology, which is applied in the field of improving the first-time efficiency of lithium-ion full-batteries, can solve problems such as lithium analysis and lithium metal safety hazards, achieve safe and reliable first-time efficiency, compensate for the loss of active lithium, and improve first-time efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) 5% of the quality of 622 nickel cobalt lithium manganese oxide in the material ratio of the positive pole piece is weighed to take Li 3 V 2 (PO 4 ) 3 The material is added to the positive electrode material, and the positive electrode sheet is made according to the normal mixing, coating, rolling, and cutting processes;

[0017] (2) The positive electrode sheet obtained in step (1) is discharged with metal lithium as the counter electrode, the lower limit of the control voltage is 1.2V, the active lithium of the negative electrode is inserted into the positive electrode, and the Li in the positive electrode sheet 3 V 2 (PO 4 ) 3 Materials intercalate lithium to obtain Li 3+x V 2 (PO 4 ) 3 (1≤x≤2);

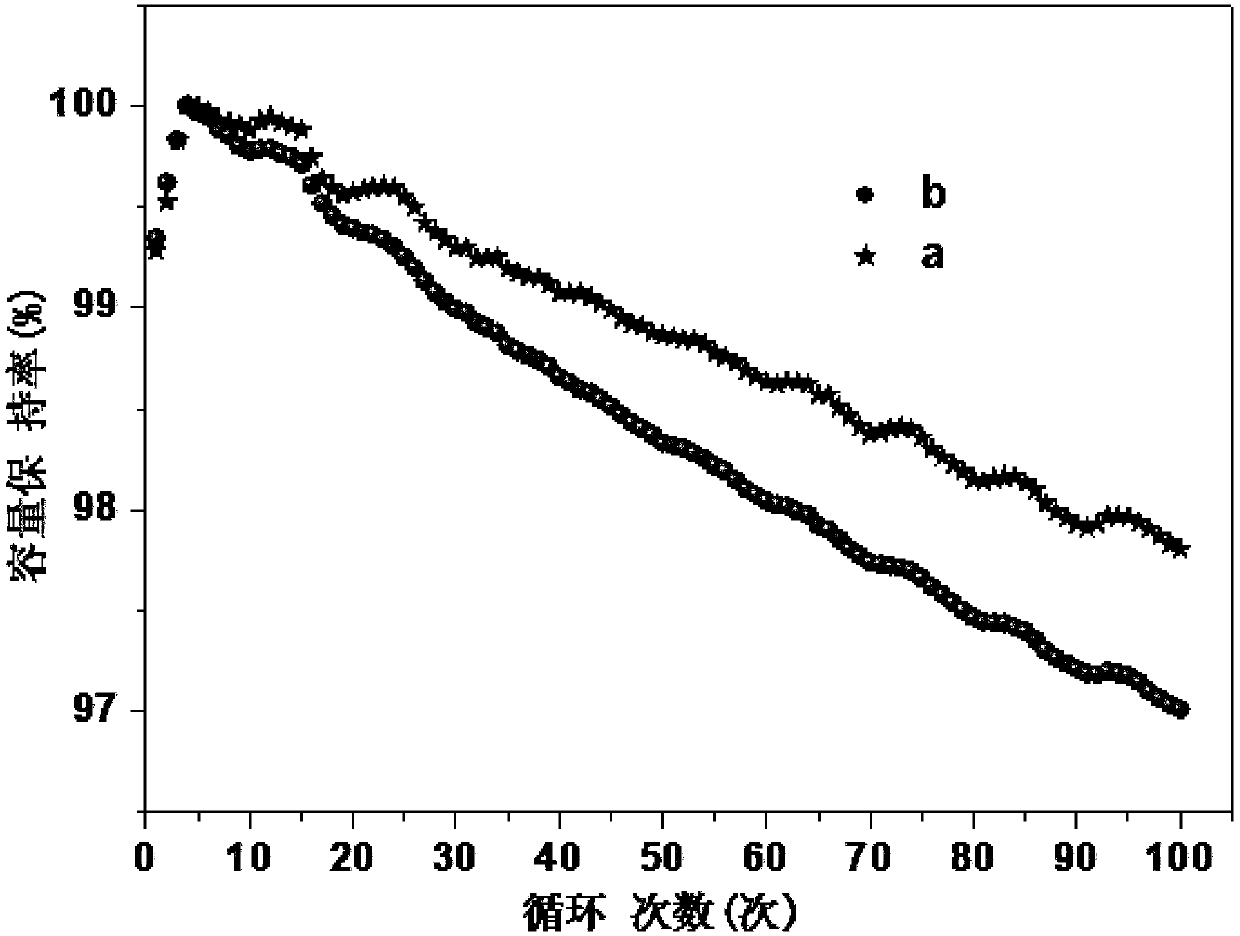

[0018] (3) Under the -40 degree dew point environment, assemble the positive electrode sheet obtained in step (2) and the SiO / C composite negative electrode sheet with a gram capacity of 450mAh / g that meets the full battery design to form a full battery. At r...

Embodiment 2

[0020] (1) Weigh Li according to 12% of the NCA mass in the material ratio of the positive pole piece. 3 V 2 (PO 4 ) 3 The material is added to the positive electrode material, and the positive electrode sheet is made according to the normal mixing, coating, rolling, and cutting processes;

[0021] (2) The positive electrode sheet obtained in step (1) is discharged with metal lithium as the counter electrode, the lower limit of the control voltage is 1.2V, the active lithium of the negative electrode is inserted into the positive electrode, and the Li in the positive electrode sheet 3 V 2 (PO 4 ) 3 Materials intercalate lithium to obtain Li 3+x V 2 (PO 4 ) 3 (1≤x≤2);

[0022] (3) Under the -40 degree dew point environment, assemble the positive electrode sheet obtained in step (2) and the SiO / C composite negative electrode sheet with a gram capacity of 650mAh / g that meets the full battery design to form a full battery. At room temperature, charge and discharge for ...

Embodiment 3

[0024] (1) Weigh Li according to 3% of the LFP mass in the material ratio of the positive pole piece. 3 V 2 (PO 4 ) 3 The material is added to the positive electrode material, and the positive electrode sheet is made according to the normal mixing, coating, rolling, and cutting processes;

[0025] (2) The positive electrode sheet obtained in step (1) is discharged with metal lithium as the counter electrode, the lower limit of the control voltage is 1.2V, the active lithium of the negative electrode is inserted into the positive electrode, and the Li in the positive electrode sheet 3 V 2 (PO 4 ) 3 Materials intercalate lithium to obtain Li 3+x V 2 (PO 4 ) 3 (1≤x≤2);

[0026](3) Under the -40 degree dew point environment, assemble the positive pole piece obtained in step (2) and the negative pole piece of hard carbon negative electrode material with a gram capacity of 400mAh / g that satisfies the design of the full battery to form a full battery. At room temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com