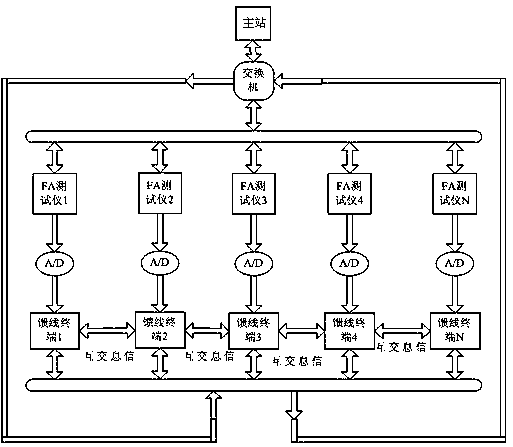

Portable intelligent distributed feeder automation test system

A feeder automation and testing system technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as the influence of communication systems that have not been considered, and achieve the effect of simplifying on-site assembly work, increasing observability, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: The main line fails

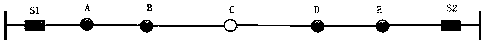

[0036] figure 2 Shown is a typical open-loop distribution network, S1, S2 are substation outlet switches, A, B, D, E are line switches, and C is a tie switch. When the distribution line is in normal operation, S1, S2, A, B, D, E are closed, C is open, the current flow on the distribution line is: S1→A→B→C, S2→E→D; now suppose that when the distribution line fails, there is at most one section error occured.

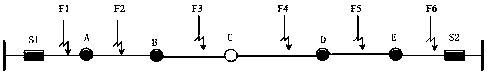

[0037] Such as image 3 As shown, it can be divided into 6 kinds of faults.

[0038] Select a feeder automation control strategy that only needs to go through one reclosure, and its control strategy is as follows:

[0039] (1) if Figure 4a As shown, when a fault occurs between S1 and A, it is recorded as event F1; when a fault occurs between S1 and A, it will be detected that there is a fault current flowing through switch S1; no fault current flows through switches A, B, D, and S2 However, due to the protection mechanism, f...

Embodiment 2

[0051] Example 2: Branch line fails

[0052] Figure 5 As shown, it is a distribution network with a branch structure. The analysis method is consistent with the analysis method in 2.1 when the main line fails. The information fed back by the FA tester and the status information of each switch generated under the automatic control strategy of the feeder to be verified are respectively The summary table is as follows:

[0053] Table A Summary of status information of each switch fed back by FA tester

[0054] (1) Status information of each switch when a transient fault event occurs

[0055]

[0056] (2) Status information of each switch when a permanent fault event occurs

[0057]

[0058] Table B summarizes the status information of each switch under the feeder automation control strategy

[0059] (1) Status information of each switch when a transient fault event occurs

[0060]

[0061] (2) Status information of each switch when a permanent fault event occurs

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com