Intelligent downhole wax removing and preventing device

A wax removal and smart well technology, applied in isolation devices, cleaning tools, boreholes/well components, etc., can solve the problems of multiple failures of well flushing valves, different wax deposition speeds, damage to downhole equipment, etc., and achieve wax removal efficiency High, improve the effect of wax removal cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

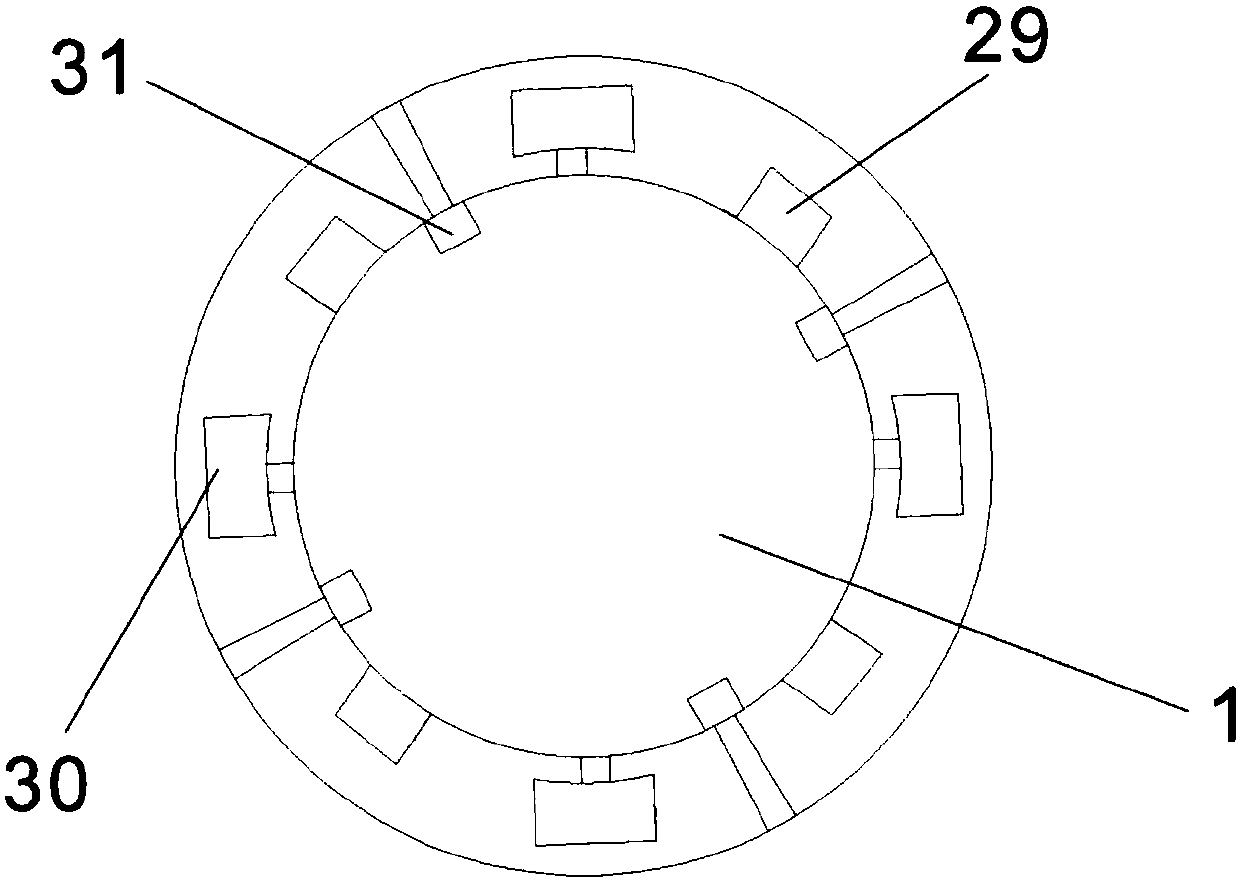

[0021] The present invention is an intelligent downhole wax removal and prevention device, the structure of which is as follows figure 1 and figure 2 As shown, it includes the following three modules that are evenly distributed on the outer wall of the oil pipe 1: a strong magnetic anti-wax module 29, a microwave heating wax removal module 30 and a chemical anti-wax removal module 31. The above three modules are all connected to the ground control box 2 located on the well. connect.

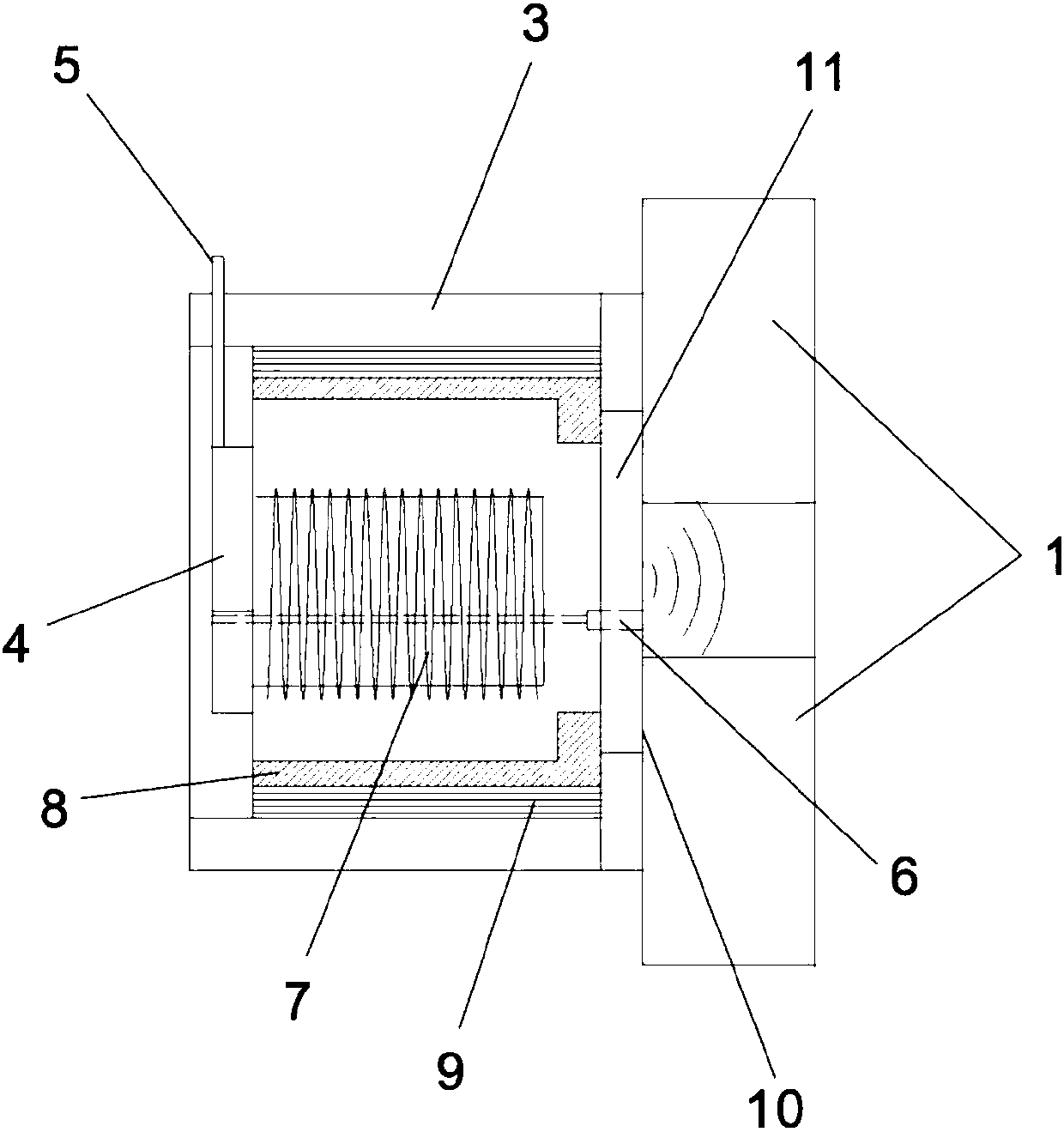

[0022] Such as image 3 As shown, the strong magnetic anti-wax module 29 includes a first airtight protective shell 3, the first airtight protective shell 3 is provided with a first control switch 4, and the first control switch 4 is respectively connected with a first cable 5 and a radiation thickness sensor 6, The first cable 5 passes through the first air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com