Downhole fire extinguishing nipple for air drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail without limitation in conjunction with the accompanying drawings and examples below.

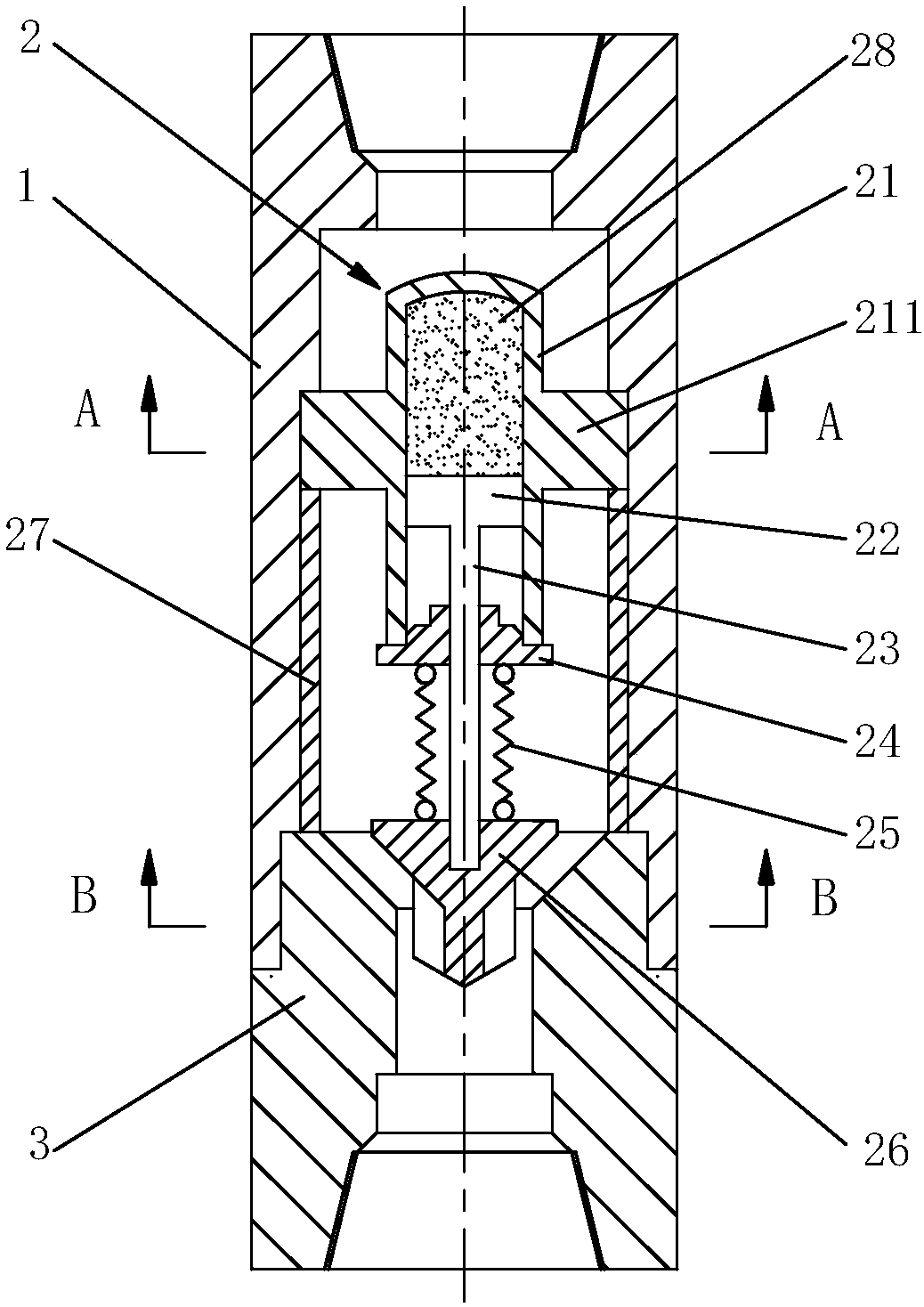

[0034] Such as figure 1 As shown, the downhole fire extinguishing nipple for air drilling according to the embodiment of the present invention includes a cylinder body 1, a lower joint 3 fixedly connected to the lower end of the cylinder body 1, and a valve core assembly 2 arranged in an axially penetrating cylinder cavity. The upper end of the cylinder body 1 is provided with a female thread for connecting with the drill string, and the lower end of the lower joint 3 is provided with a female thread for connecting with a drill bit or an air hammer.

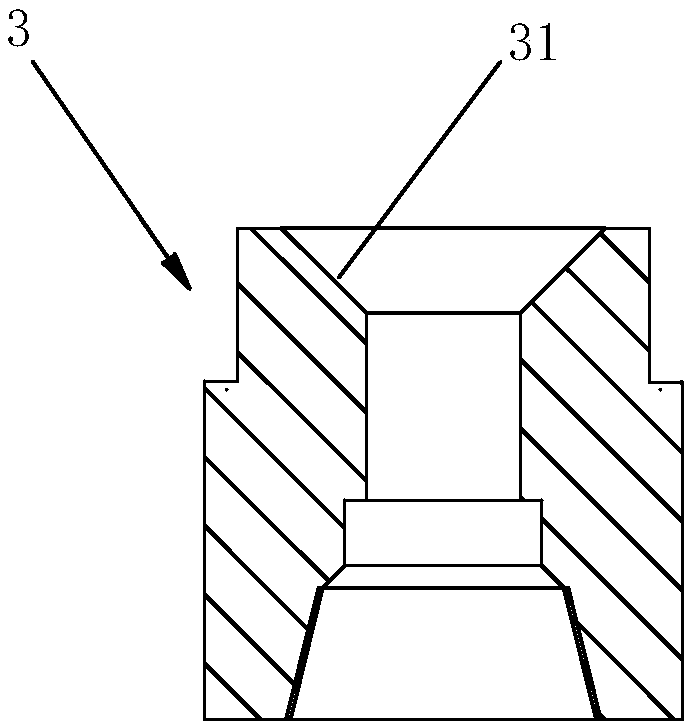

[0035] Such as image 3 As shown, wherein, the lower joint 3 has a lower joint inner cavity penetrating in the axial direction, and the upper end of the lower joint inner cavity is provided with a lower joint inner tapered surface 31 .

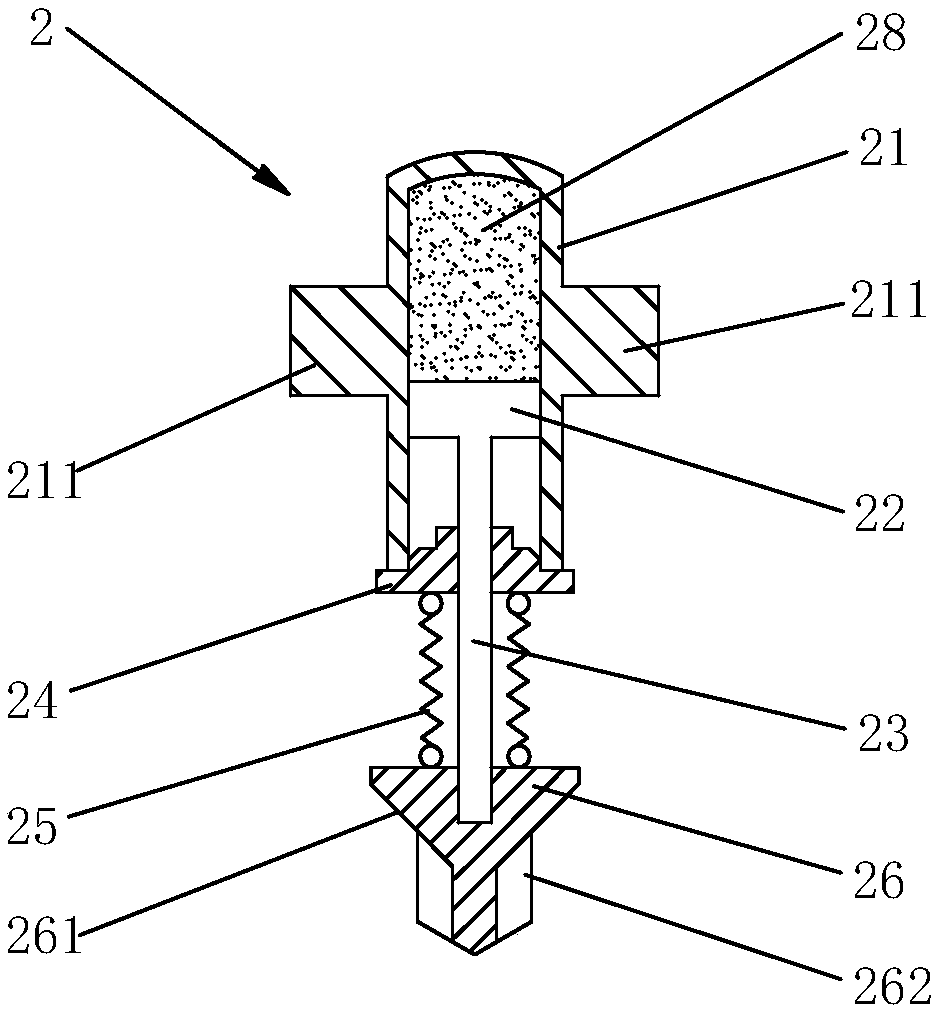

[0036] Such as figure 2 As shown, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com