Padding and drying integrated machine

An all-in-one, padding technology, applied in the processing of textile material carriers, liquid/gas/vapor textile material processing, liquid/gas/vapor removal by air jet method, etc., can solve the problem of increased labor costs, large size, low efficiency, etc. problem, to achieve the effect of high work efficiency, high drying efficiency, and improved impregnation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

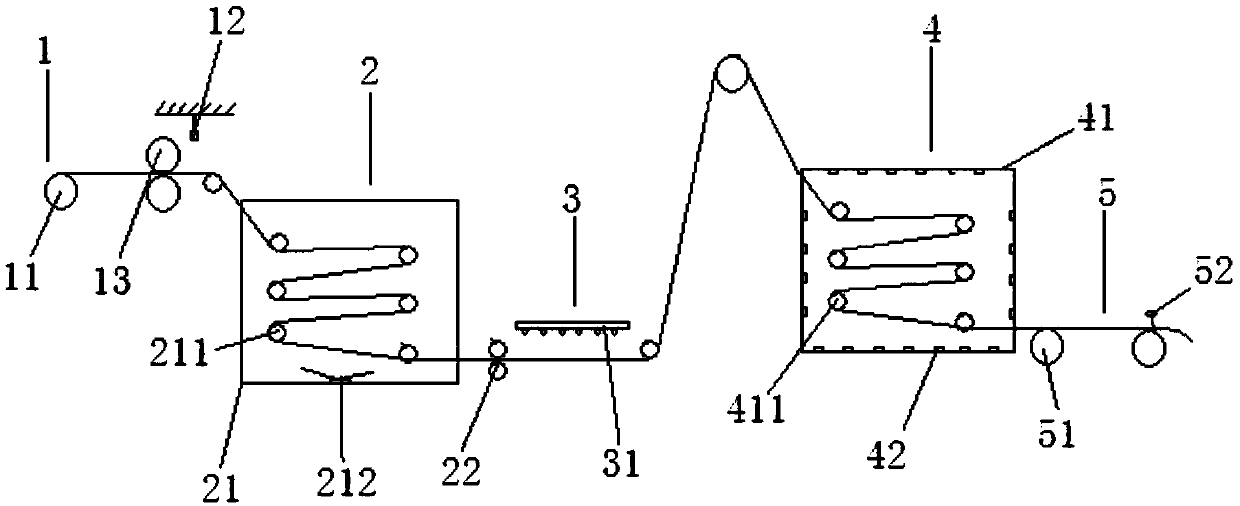

[0022] An integrated padding and drying machine, comprising an introduction mechanism 1, an impregnation device 2, a preheating device 3, and a drying device 4 sequentially connected by a conveyor belt; the impregnation device 2 includes an impregnation cylinder 21, a water rolling mechanism 22, and Two rows of impregnating rollers arranged in a staggered position are arranged in the cylinder 21, and the impregnating rollers are sequentially connected by a conveyor belt; Heating further removes the moisture in the fabric; the drying device 4 includes a sealed oven 41, and the sealed oven 41 is equipped with two rows of heating rollers 411 arranged in a staggered position. The air outlet 42; the stirring device 212 is arranged at the bottom of the dipping cylinder 21; the introduction mechanism 1 includes the introduction roller shaft 11 and the conveyor belt arranged at both ends of the head and the tail, and the introduction roller shaft 11 is connected with the transmission m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com