Slump-loss-resistant and mud-resistant polycarboxylic acid with high performance and preparation method of polycarboxylic acid

A mud-resistant, high-performance technology, applied in the field of building materials, can solve the problems of high equipment requirements, poor adaptability of sand and gravel materials, singleness, etc., and achieve the effect of high water reduction rate and good slump retention ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of high-performance anti-slump anti-sludge type polycarboxylic acid, its steps are as follows: add 300g isopentenol polyoxyethylene ether, 250g deionized water in the four-necked flask of 1L capacity, stir and dissolve, after dissolving completely Add solution C directly to the bottom of the reaction kettle, and then add solution A and solution B dropwise at the same time ten minutes later; add solution A dropwise for 4 hours, and solution B dropwise for 4.5 hours, if the system temperature exceeds 45°C during the dropwise addition, turn on the cooling system Cool down to keep the temperature in the reactor at 42-45°C; after the dropwise addition, mature for 2 hours, add 169g of deionized water to adjust the obtained product to 40% solid content; that is, the finished product PC- 1.

[0028] The A solution is composed of 25g acrylic acid, 35g hydroxyethyl acrylate, 30g dimethylaminoethyl methacrylate and 30g deionized water;

[0029] Descri...

Embodiment 2

[0032] A kind of preparation method of high performance anti-cold mud type polycarboxylic acid, its steps are as follows: add 300g isopentenol polyoxyethylene ether, 5g acrylic acid and 250g deionized water in the four-necked flask of 1L capacity, stir and dissolve, Add 3.5g of ammonium persulfate after the dissolution is complete, then add solution A, solution B and solution C dropwise after ten minutes; add solution A for 4 hours, solution B and solution C for 4.5 hours, if the system temperature exceeds 45°C, turn on the cooling system to cool down, so that the temperature in the reactor is maintained at 42-45°C; after the dropwise addition, mature for 2 hours, add 76g of deionized water to adjust the obtained product to 40% solid content; obtain polycarboxylic acid High performance slump retaining agent PC-2.

[0033] The A solution is composed of 20g acrylic acid, 35g hydroxyethyl acrylate, 30g dimethylaminoethyl methacrylate and 30g deionized water;

[0034] Described B...

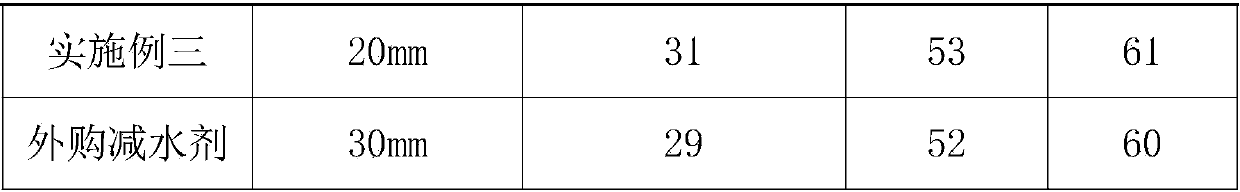

Embodiment 3

[0037] A preparation method of high-performance anti-cold and anti-mud polycarboxylic acid, the steps are as follows: add 300g prenol polyoxyethylene ether and 250g deionized water into a four-necked flask with a capacity of 1L, stir and dissolve, and dissolve it completely Add 3.5g of ammonium persulfate, and add solution A, solution B and solution C dropwise after ten minutes; add solution A for 4 hours, and solution B and solution C for 4.5 hours. If the temperature of the system exceeds 45°C during the dropping process, Then turn on the cooling system to cool down, so that the temperature in the reactor is maintained at 42-45°C; after the dropwise addition, mature for 1.5 hours, add 83g of deionized water to adjust the obtained product to 40% solid content. That is to obtain the finished product PC-3 of polycarboxylic acid high-performance slump-retaining agent.

[0038] The A solution is composed of 25g acrylic acid, 20g hydroxyethyl acrylate, 15g methyl acrylate, 30g dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com