Energy-saving method for separating methylbenzene and 2-methoxyethanol mixture by extractive distillation

A methoxyethanol and extractive distillation technology is applied in the energy saving field of extractive distillation and separation of a mixture of toluene and 2-methoxyethanol, and can solve the problems of low product purity of toluene, low product purity and yield, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

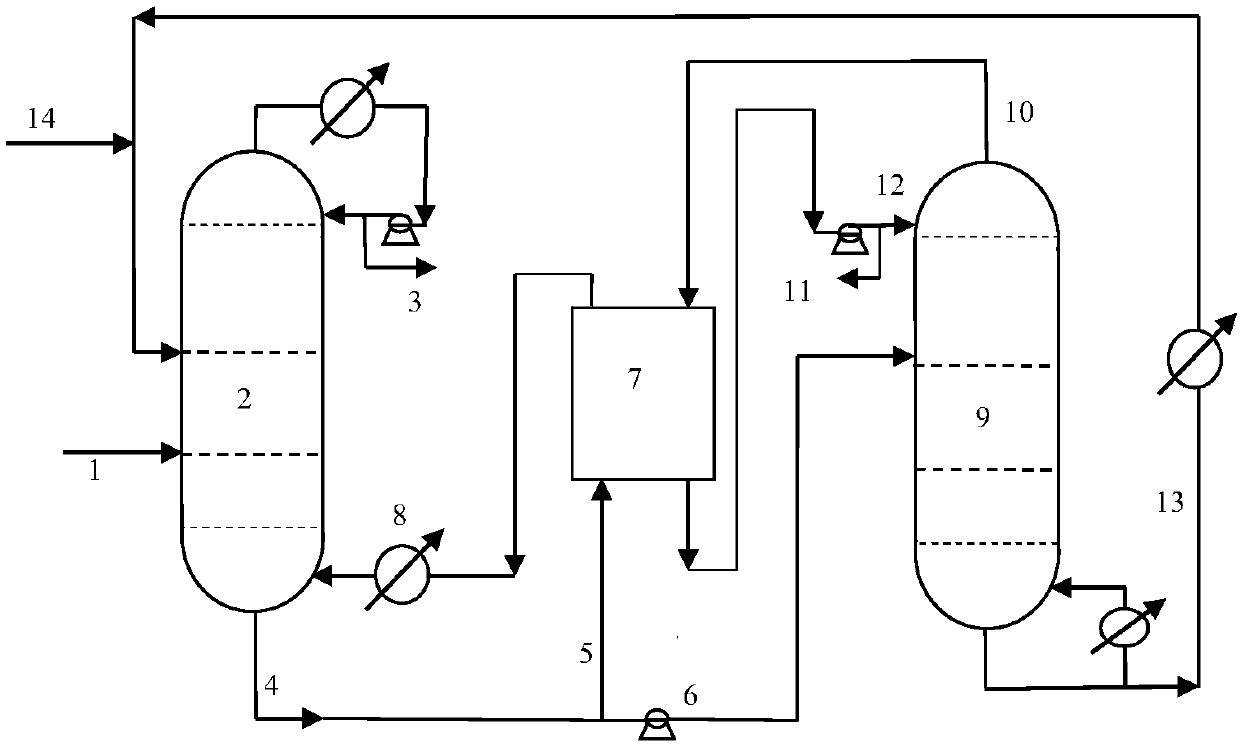

[0025] Take 8411.8kg / h of toluene content as 54.8wt% toluene and 2-methoxyethanol mixture as example:

[0026] The extractive distillation column has a total of 40 trays, the reflux ratio is 0.89, and the operating pressure is 1atm. The fresh material enters the extractive distillation column from the 29th tray, and the flow rate of the extractant (dimethyl sulfoxide) is 5860.1kg / h The rate (molar ratio is 0.75) enters the extractive distillation column from the 8th tray. The temperature at the top of the extractive distillation column is 110.7°C, the heat load of the condenser is 0.88MW, the temperature at the bottom of the tower is 155.3°C, and the heat load of the supplementary reboiler is 1.04MW. The extraction agent recovery tower has a total of 20 trays, the reflux ratio is 0.81, and the operating pressure is 3.3 atm. The mixed solution of 2-methoxyethanol and extractant enters the extraction agent recovery tower from the eighth tray, and the extraction agent recovery to...

Embodiment 2

[0028] Take 8411.8kg / h of toluene content as 54.8wt% toluene and 2-methoxyethanol mixture as example:

[0029] There are 35 trays in the extractive distillation column, the reflux ratio is 1.18, and the operating pressure is 0.8atm. The fresh material enters the extractive distillation column from the 25th tray, and the flow rate of the extractant (dimethyl sulfoxide) is 6250.8kg / The rate of h (molar ratio is 0.80) enters the extractive distillation column from the 8th tray. The temperature at the top of the extractive distillation column is 103.0°C, the heat load of the condenser is 1.03MW, the temperature at the bottom of the column is 148.5°C, and the heat load of the supplementary reboiler is 0.69MW. The extraction agent recovery tower has a total of 15 trays, the reflux ratio is 1.70, and the operating pressure is 3.0atm. The mixed solution of 2-methoxyethanol and extractant enters the extraction agent recovery tower from the sixth tray, and the extraction agent recovery...

Embodiment 3

[0031] Take 8411.8kg / h of toluene content as 54.8wt% toluene and 2-methoxyethanol mixture as example:

[0032]There are 30 trays in the extractive distillation column, the reflux ratio is 1.63, and the operating pressure is 0.5atm. The fresh material enters the extractive distillation column from the 21st tray, and the flow rate of the extractant (dimethyl sulfoxide) is 8204.2kg / The rate of h (molar ratio is 1.05) enters the extractive distillation column from the 7th tray. The temperature at the top of the extractive distillation column is 88.0°C, the heat load of the condenser is 1.27MW, the temperature at the bottom of the tower is 137.1°C, and the heat load of the supplementary reboiler is 0.61MW. The extraction agent recovery tower has a total of 10 trays, the reflux ratio is 2.20, and the operating pressure is 2.0atm. The mixed solution of 2-methoxyethanol and extractant enters the extraction agent recovery tower from the sixth tray, and the extraction agent recovery to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com