A system and method for treating waste oil-based drilling mud

An oil-based drilling and treatment method technology, which is applied in the direction of sludge treatment, mining wastewater treatment, water/sludge/sewage treatment, etc., can solve problems that are difficult to promote and use on a large scale, without oil recovery, and the amount of extractant used Large and other problems, to achieve the effect of ingenious design, realization of recycling, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make it easier for those skilled in the art to understand the technical solution of this patent, and at the same time, in order to make the technical purpose, technical solution and beneficial effect of this patent clearer, and to fully support the protection scope of the claims, the following is a specific case in the form of this patent. The technical solution of the patent makes further and more detailed descriptions.

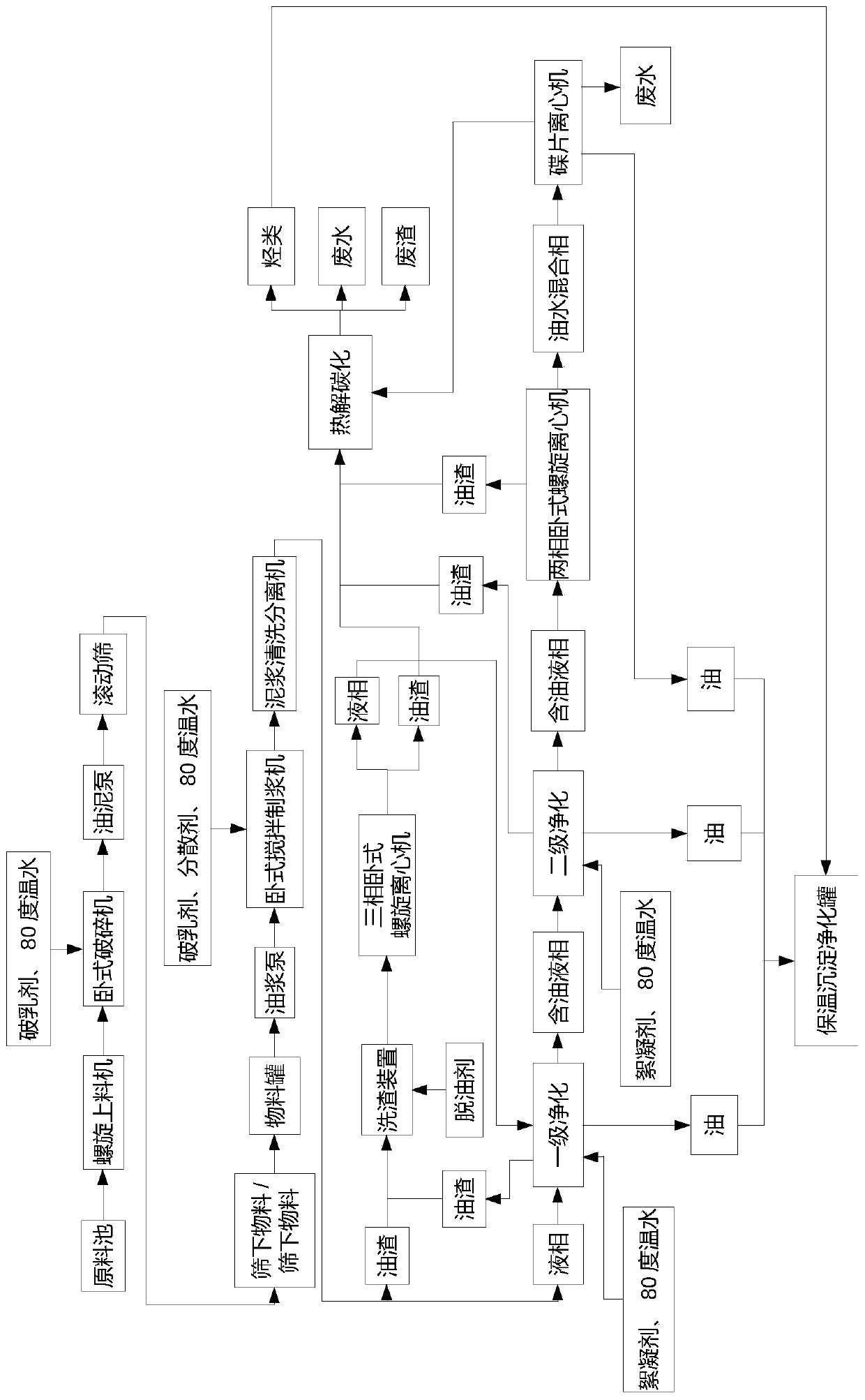

[0032] Such asfigure 1 As shown, a waste oil-based drilling mud treatment system is used to separate oil, water and slag components in oil sludge, including crushing and screening subsystems, pulping subsystems, oil purification subsystems, slag washing subsystems and Pyrolysis and carbonization subsystem; the crushing and screening subsystem includes a crusher, a rolling screen and an oil sludge pump for transporting the sludge from the crusher to the rolling screen, and the crusher is provided with a first demulsifier dosing device and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com