Easy-to-place enameled wire guiding device

A guiding device and enameled wire technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, and thin material processing, etc., can solve problems such as inefficient maintenance methods and damage to guide wheel grooves, simplify installation and replacement steps, and reduce installation costs. The effect of reducing difficulty and involvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

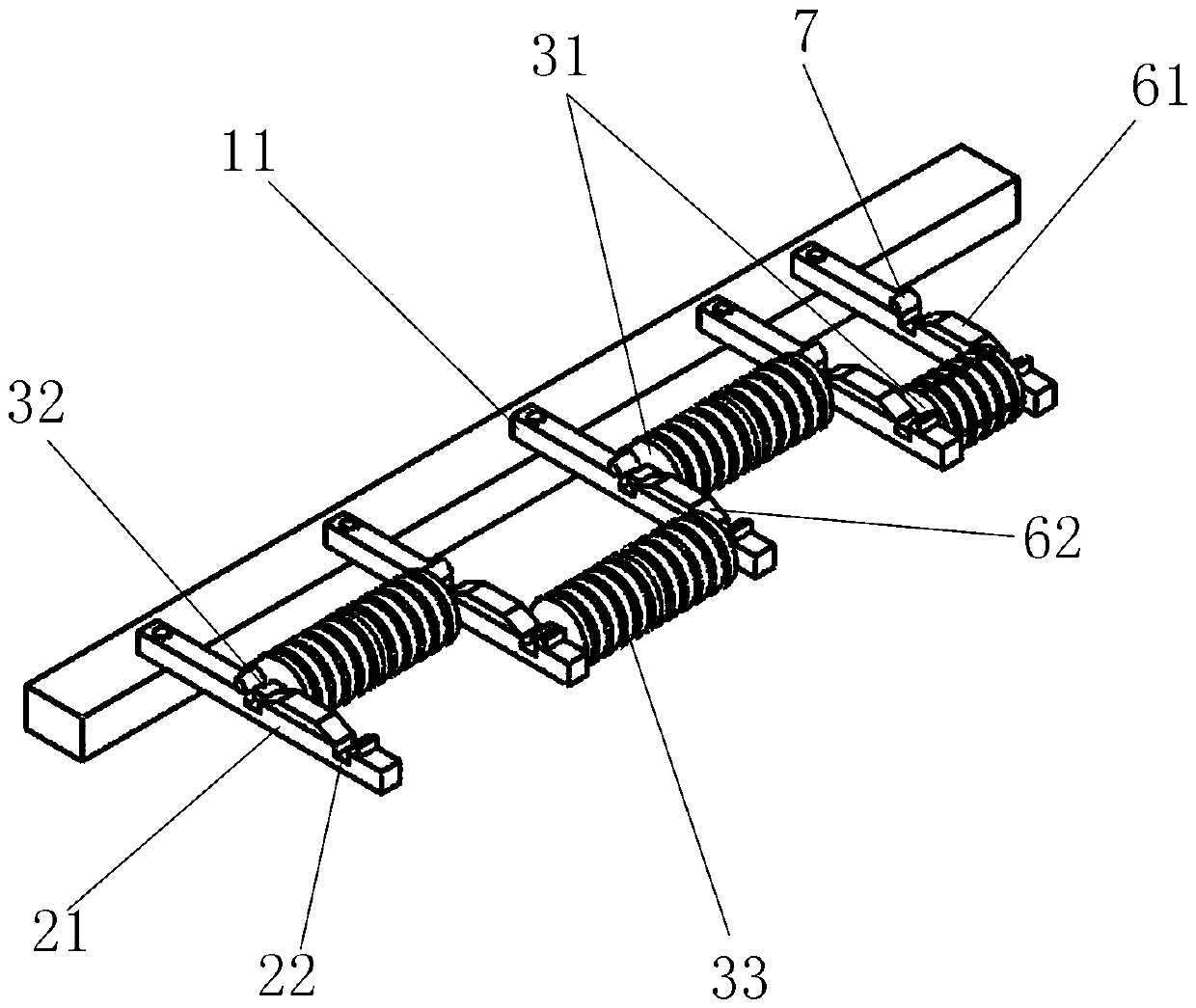

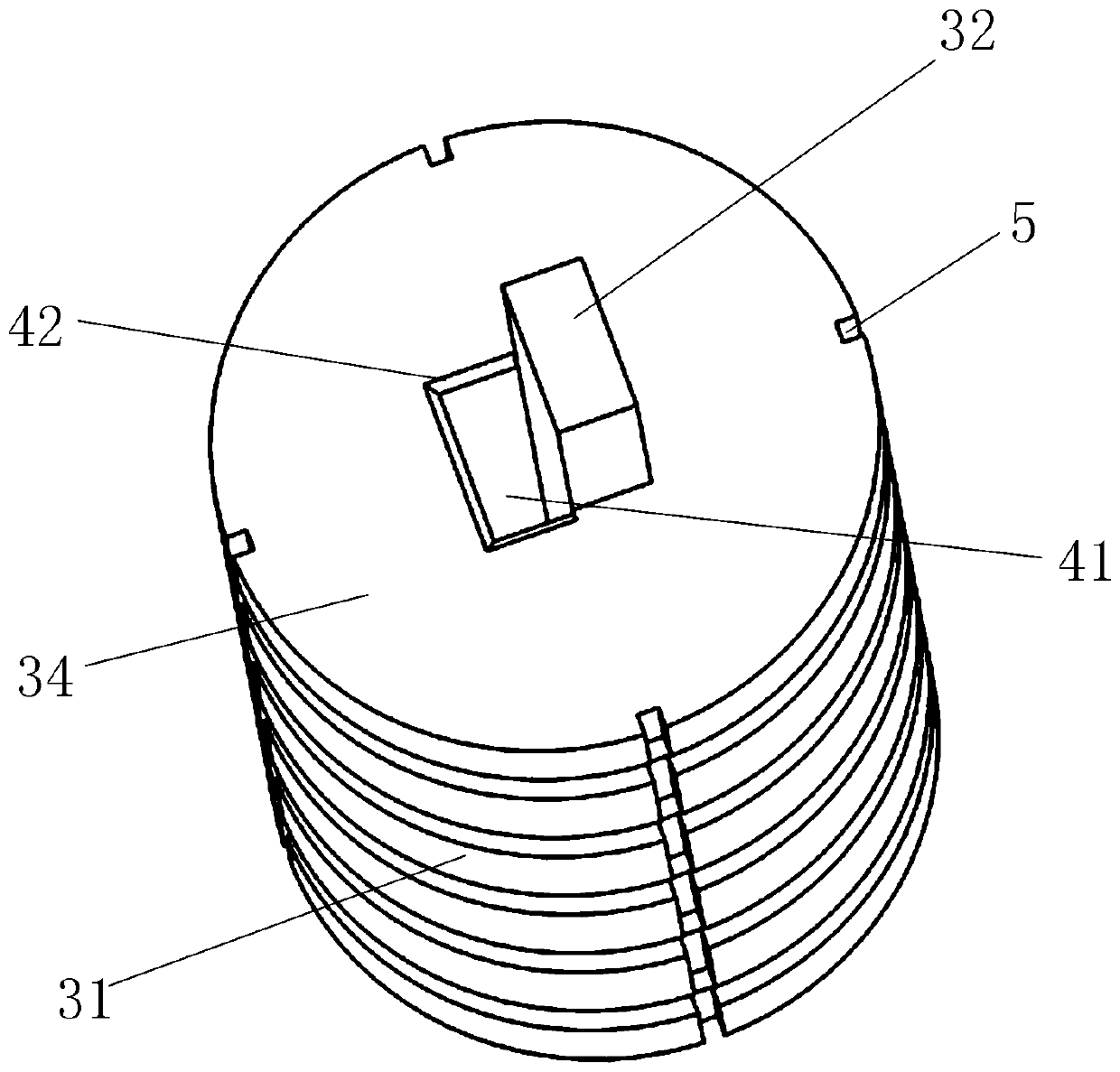

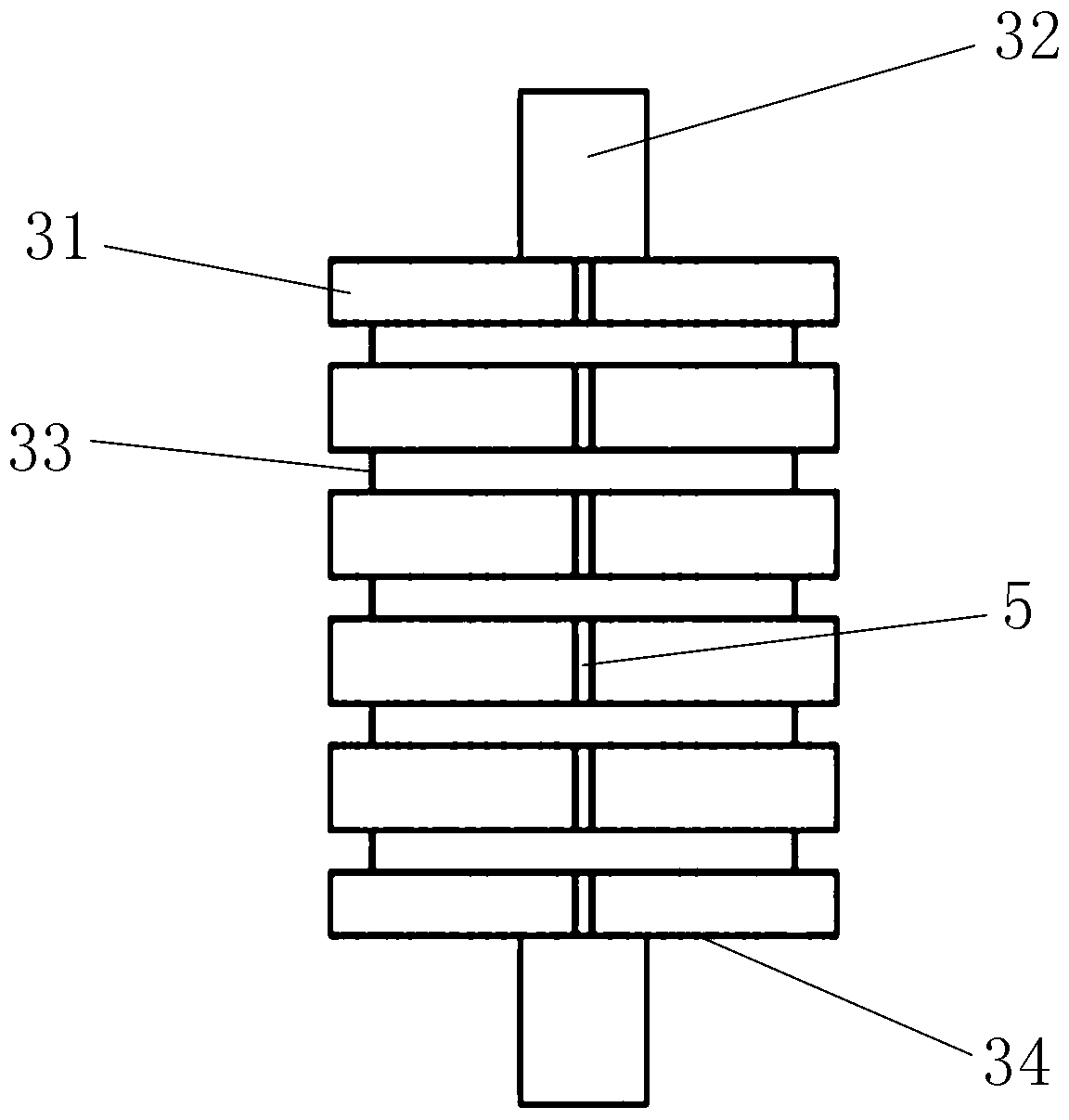

[0036] Example 1, such as figure 1Shown is an overall schematic diagram of an easy-to-place enameled wire guide device, an easy-to-place enameled wire guide device, which includes a fixed rod used to be fixedly connected to the enamelling machine, and shelves arranged at intervals in the length direction of the fixed rod The wheel rod 11 and the guide wheel for guiding the enameled wire, the frame wheel rod 11 includes a fixed part and a shaft 21 for being fixedly connected with the fixed rod, and the shaft 21 is horizontal from the upper surface of the fixed rod to the side of the fixed rod The extended straight bar has a wheel groove 22 for placing guide wheels on the side of the shaft 21 away from the fixed rod. The wheel groove 22 is a groove extending downward from the upper surface of the shaft 21 and arranged at intervals. The guide wheels include The wheel body 31 and the wheel bar 32 for being embedded in the wheel groove 22, the wheel body 31 is a cylindrical block, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com